Nonwoven Geotextile Fabric

A Nonwoven Geotextile is a permeable fabric that separates poor soils, provides high flow, and at certain strengths stabilizes the subgrade. A needle punch nonwoven geotextile is made from polypropylene fiber and has a felt-like texture.

Nonwoven geotextile fabric is also known as filter fabric and drainage fabric.

Common Applications

Nonwoven geotextiles are used on construction sites and landscaping projects. Some common applications for nonwoven geotextiles include:

- Soil separation

- Drainage layer

- Pipe wrap

- French drain

- Soil stabilization

- Erosion Control

- Asphalt Overlay

The application determines what type of nonwoven geotextile fabric you will need. For example, pipe wrap and French drain projects require a lightweight nonwoven fabric. Roadway stabilization projects, on the other hand, require medium to heavyweight filter fabrics.

Types of Nonwoven Geotextiles

Nonwoven geotextile fabrics are categorized by application and weight. The broad application categories include Civil Nonwovens, Environmental Fabrics and Paving Fabrics.

You can further categorize nonwoven fabrics as lightweight, medium weight and heavyweight geotextile fabrics.

Civil Nonwovens

Environmental Fabrics

Paving Fabrics

Civil Nonwoven Geotextiles

This category includes lightweight, medium weight and heavyweight nonwoven geotextile fabrics. Civil Nonwovens are used for a variety of applications ranging from heavy civil construction to landscaping projects.

Lightweight

Drainage | Separation

Lightweight nonwoven geotextiles are most commonly used as a drainage and separation layer. Typical applications include pipe wrap on road and utility projects, filter fabric for landscaping projects and drainage fabric for retention and detention systems. These geotextiles range from 3.0oz to 4.5oz.

Data Sheets

GT135 – 3.5oz

GT140 – 4.0oz

GT142 – 4.5oz

Medium Weight

Separation | Stabilization

Medium weight nonwoven geotextile fabrics are used for drainage, separation and stabilization. These fabrics have a greater tensile strength than the lightweight fabrics but lower permittivity. That means they are stronger than the lightweight geotextiles but not as permeable.

Medium Weight Nonwoven Geotextiles work great for drainage and are excellent at separating soils. When used for separation, medium weight geotextiles prevent contamination between soil layers while still allowing water to pass through the subgrade. This group of geotextiles is often used in combination with a geogrid to achieve maximum stabilization and separation on unstable subgrades.

Data Sheets

GT160 – 6.0oz

GT170 – 7.0oz

GT180 – 8.0oz

Heavyweight

Stabilization | Cushion

Heavyweight nonwoven fabrics act as a soft separating geotextile layer between rough aggregate and other geosynthetic structures. The felt-like fabric provides protection for sensitive structures such as geo-membranes and liners that can be compromised if they are punctured, ripped or torn. Heavyweight nonwoven fabrics are also applied for stabilization under roadways.

Data Sheets

GT180 – 8.0oz

GT110 – 10.0oz

GT112 – 12.0oz

GT116 – 16.0oz

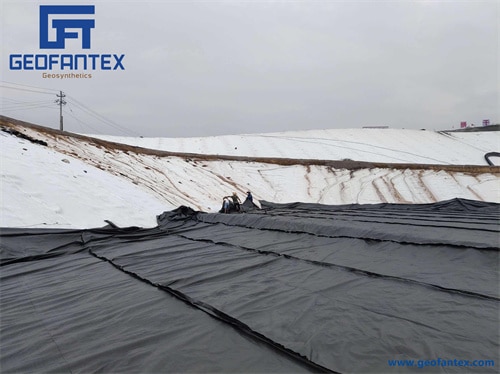

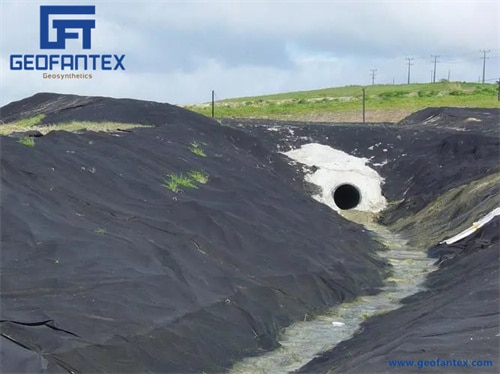

Environmental Nonwoven Geotextiles

Separation | Cushion

Environmental nonwoven geotextile fabrics line landfill cells and stormwater ponds.

On landfills, these needle-punch nonwovens separate stone from geosynthetic liners. The environmental nonwoven geotextile provides a cushion layer and separation layer to also prevent contamination between soil/stone and trash.

In stormwater ponds, environmental fabrics separate groundwater from the retention pond while providing a cushion layer under the geosynthetic liner.

Environmental Geotextiles Data Sheets

GE140 – 4.0oz

GE160 – 6.0oz

GE170 – 7.0oz

GE180 – 8.0oz

GE110 – 10.0oz

GE112 – 12.0oz

GE114 – 14.0oz

GE116 – 16.0oz

What is the difference between a civil nonwoven and an environmental nonwoven?

Weight is the critical difference between a civil nonwoven and an environmental nonwoven. Weight is reported as a typical value for a civil nonwoven. A typical value represents the mean value. This means 50% of the values can exceed the typical value and 50% of the values can be lower than the typical value.

Environmental geotextile’s weight is reported by the Minimum Average Roll Value, also known as MARV. MARV is derived from the average value less two standard deviations. As a result, geotextiles testing according to MARV is more accurate. When comparing civil nonwovens to environmental nonwovens, the MARV weight as tested and reported for environmental nonwovens is more accurate than the typical value weight reported for civil nonwovens.

Paving Fabrics

Separation | Cushion

A needle-punch nonwoven Paving Fabric relieves stress between road layers. This reduces cracking and deterioration, increases the road’s flexibility, and ultimately aims to increase the road’s lifespan.

Paving Fabrics are bonded to the road surface and saturated with bitumen (a petroleum based liquid binding agent found in asphalt). This layer seals the pavement and waterproofs the overlay.

Paving Fabric Data Sheets

GC130

GC140

GC150

GC160

Explore more geosynthetics

Woven Geotextiles

Learn More

Geocells

Learn More

High Strength Geotextiles and Geogrid

Learn More

Need a price?

Contact our sales team to get started.

Call Us