Select Links Q and A Photos Guides and Manuals

Links Q and A Photos Guides and Manuals

Related Product(s)

US 200,

US 250,

US 270,

US 315

Our Products At Work

Chatfield College – Case Study,

Precaster’s Yard – Stacy, Minnesota – Case Study

Related Sections

Geotextiles,

Woven Geotextiles

Product Lines US Fabrics Linecard

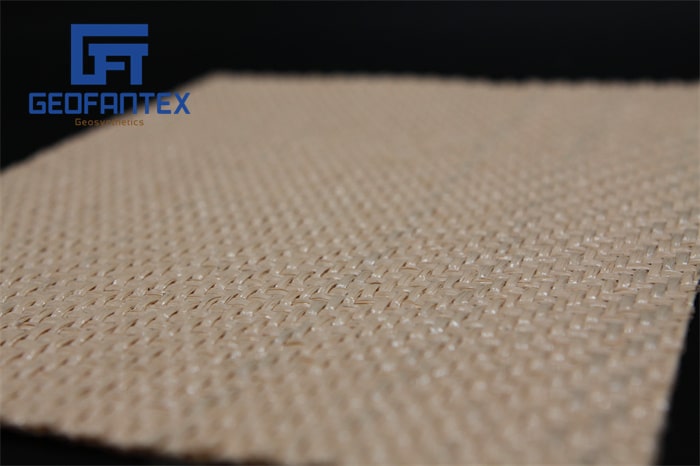

US Fabrics offers cost-effective woven geotextiles made from polypropylene slit film yarns. These ground stabilization geotextiles, sometimes known as Driveway Fabric, have high tensile strength at low elongations. They reduce maintenance costs and improve the performance of paved and unpaved surfaces.

Woven slit-films are made from cutting sheets of impermeable liner into narrow strips or tapes and then weaving them similar to a basket weave. These are used for separation/stabilization applications, such as parking lots, driveways, construction site entrances or under foundations and building pads. While they are permeable, they are not typically used in applications requiring filtration as the main function.

- Minimizes Rutting

- Improves Performance

- Reduces Maintenance Costs

- Prevents Intermixing of Aggregate & Soil

- Cost-Effective

- Affordable “Aggregate Insurance”

- Saves Time & Money

- High Tensile Strength

Woven geotextiles used for ground stabilization minimize rutting and prevent intermixing of the aggregate with the soft soils below. Think of woven geotextiles as affordable insurance for your aggregate. They save time and money by reducing or eliminating the need for additional rock.

Woven geotextiles are placed between the aggregate and the subgrade to stabilize the soil, preserve the aggregate and reinforce the surrounding soil. They will also keep mud below the rock from “pumping” up and help keep cleanup to a minimum.

If you are building a road, constructing a parking lot, stabilizing material staging areas or repairing/installing a gravel driveway, woven geotextiles perform at a high level and save time and money.