What is a geocomposite liner?

The geocomposite consists of a tri-planar geonet heat-laminated on both sides with a nonwoven geotextile. The tri-planar structure consists of middle ribs that provide direct flow, along with diagonally placed top and bottom ribs to minimize geotextile intrusion.

A geocomposite liner is a type of liner that consists of multiple layers of different materials, typically including geotextiles, geomembranes, and/or geonets. These layers are bonded together to create a single, durable material that is designed to prevent the escape of liquids or gases from a containment area.

Geocomposite liners are commonly used in a variety of applications, such as landfill liners, pond liners, and mining liners. They are often preferred over traditional liners made from a single material, as the combination of multiple materials allows for greater strength and durability, as well as improved resistance to punctures and tears.

The specific composition and thickness of a geocomposite liner will depend on the specific application and the requirements of the containment area. Overall, geocomposite liners are an important tool for ensuring environmental protection and safety in a variety of industries.

- 16 ounce geocomposite liner

A 16 ounce geocomposite liner is a type of geocomposite liner that has a total weight of 16 ounces per square yard. This weight is a measure of the overall density and thickness of the liner, and it is determined by the combination of materials used in its construction.

The specific materials used in a 16 ounce geocomposite liner will depend on the intended application, but it may include layers of geotextiles, geomembranes, and/or geonets. The combination of these materials provides a strong and durable liner that is capable of withstanding the stresses of the environment it is designed to contain.

16 ounce geocomposite liners are commonly used in applications such as landfill liners, pond liners, and mining liners, where they provide an effective barrier against the escape of liquids or gases. The thickness and composition of a geocomposite liner should be carefully chosen to match the specific requirements of the containment area and the environmental regulations in place.

- 8 ounce geocomposite liner

An 8 ounce geocomposite liner is a type of geocomposite liner that has a total weight of 8 ounces per square yard. This weight is a measure of the overall density and thickness of the liner, and it is determined by the combination of materials used in its construction.

The specific materials used in an 8 ounce geocomposite liner will depend on the intended application, but it may include layers of geotextiles, geomembranes, and/or geonets. While lighter in weight than a 16 ounce liner, an 8 ounce geocomposite liner still provides a strong and durable barrier against the escape of liquids or gases, making it suitable for use in certain applications.

8 ounce geocomposite liners may be used in a variety of applications, such as landscaping and garden projects, erosion control, and temporary barriers. However, it is important to carefully consider the specific requirements of the containment area and environmental regulations before selecting a liner of any weight or composition.

- 20 ounce geocomposite liner

A 20 ounce geocomposite liner is a type of geocomposite liner that has a total weight of 20 ounces per square yard. This weight is a measure of the overall density and thickness of the liner, and it is determined by the combination of materials used in its construction.

The specific materials used in a 20 ounce geocomposite liner will depend on the intended application, but it may include layers of geotextiles, geomembranes, and/or geonets. The increased weight and thickness of the liner compared to lighter options such as 8 or 16 ounce liners provides greater strength and durability, making it suitable for use in more demanding applications.

20 ounce geocomposite liners are commonly used in applications such as landfill liners, pond liners, and mining liners, where they provide a robust barrier against the escape of liquids or gases. The thickness and composition of a geocomposite liner should be carefully chosen to match the specific requirements of the containment area and the environmental regulations in place.

- 280 ounce geocomposite liner

A 280 ounce geocomposite liner is an extremely heavy-duty type of geocomposite liner that has a total weight of 280 ounces per square yard. This weight is a measure of the overall density and thickness of the liner, and it is determined by the combination of materials used in its construction.

The specific materials used in a 280 ounce geocomposite liner will depend on the intended application, but it typically includes multiple layers of geotextiles, geomembranes, and/or geonets, as well as additional reinforcing materials such as geogrids. This combination of materials provides an incredibly strong and durable liner that is capable of withstanding even the most demanding applications.

280 ounce geocomposite liners are typically used in applications where a high level of protection is required, such as hazardous waste containment, industrial liners, and secondary containment systems. The thickness and composition of a geocomposite liner should always be carefully selected to match the specific requirements of the containment area and the environmental regulations in place.

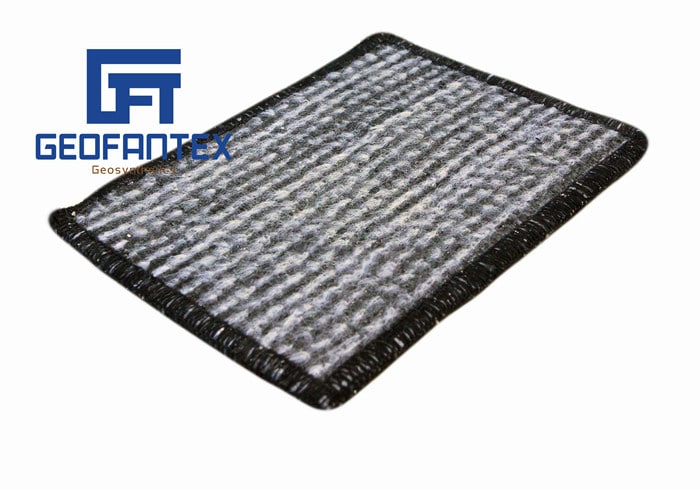

Geosynthetic clay liner

Geosynthetic clay liners (GCLs) are factory manufactured hydraulic barriers consisting of a layer of bentonite or other very low-permeability material supported by geotextiles and/or geomembranes, mechanically held together by needling, stitching, or chemical adhesives. Due to environmental laws, any seepage from landfills must be collected and properly disposed of, otherwise contamination of the surrounding ground water could cause major environmental and/or ecological problems. The lower the hydraulic conductivity the more effective the GCL will be at retaining seepage inside of the landfill. Bentonite composed predominantly (>70%) of montmorillonite or other expansive clays, are preferred and most commonly used in GCLs. A general GCL construction would consist of two layers of geosynthetics stitched together enclosing a layer of natural or processed sodium bentonite. Typically, woven and/or non-woven textile geosynthetics are used, however polyethylene or geomembrane layers or geogrid geotextiles materials have also been incorporated into the design or in place of a textile layer to increase strength. GCLs are produced by several large companies in North America, Europe, and Asia. The United States Environmental Protection Agency currently regulates landfill construction and design in the US through several legislations

What does a geosynthetic clay liner do?

Function. The engineering function of a GCL is containment as a hydraulic barrier to water, leachate or other liquids and sometimes gases. As such, they are used as replacements for either compacted clay liners or geomembranes, or they are used in a composite manner to augment the more traditional liner materials.

The wide range of GCL uses include landfill caps and base liner applications, dams, canals, ponds, rivers and lakes, and even waterproofing of buildings and similar structures.