Geofantex Geosynthetics

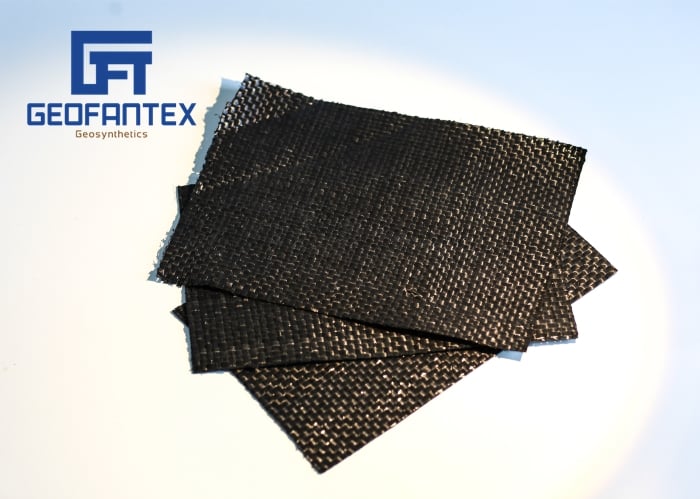

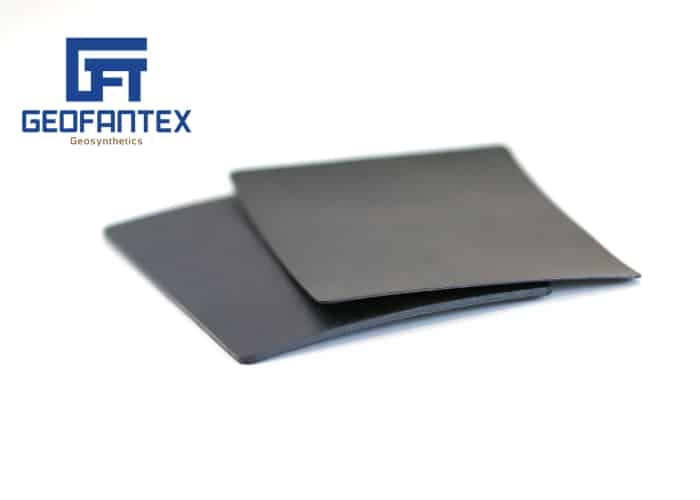

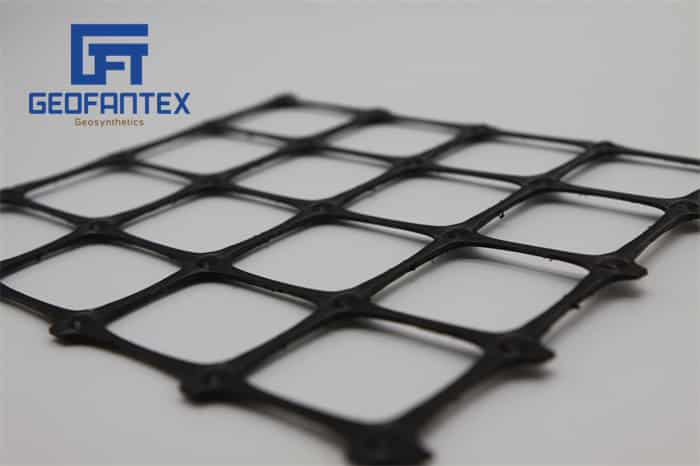

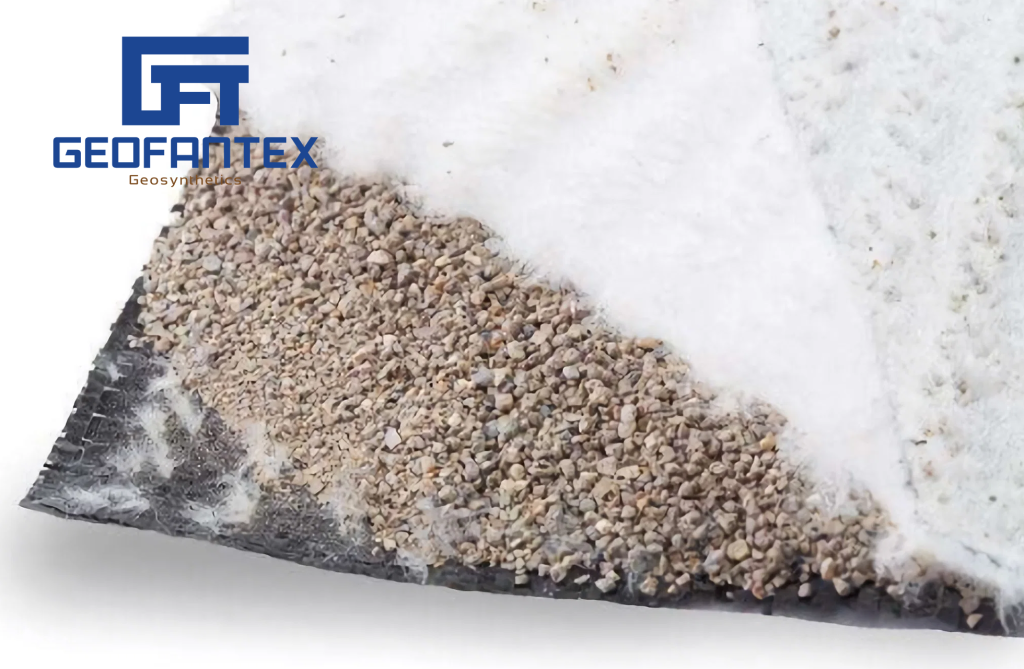

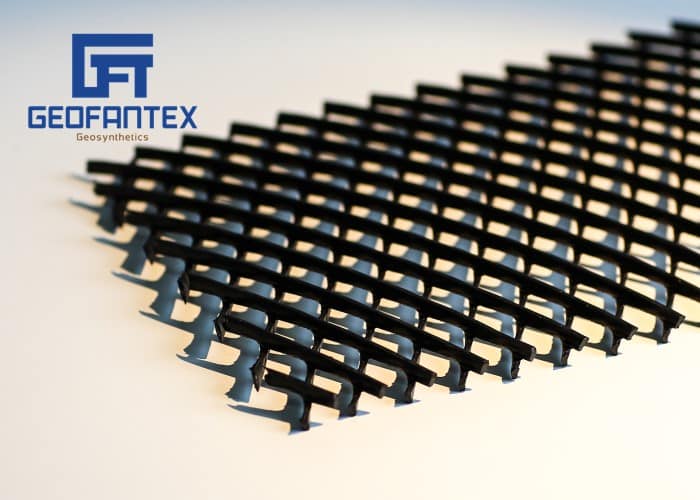

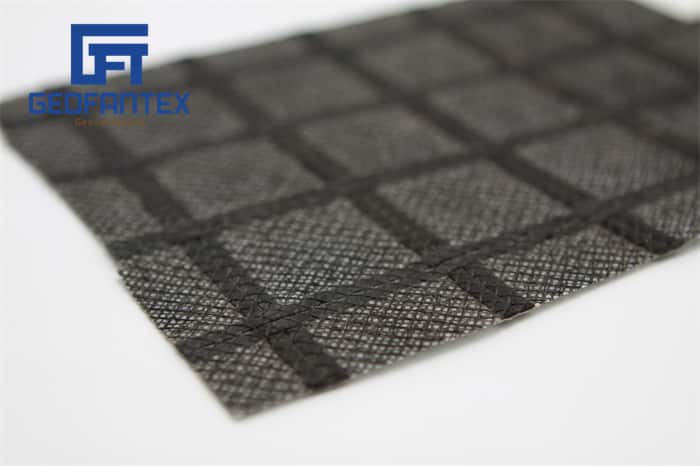

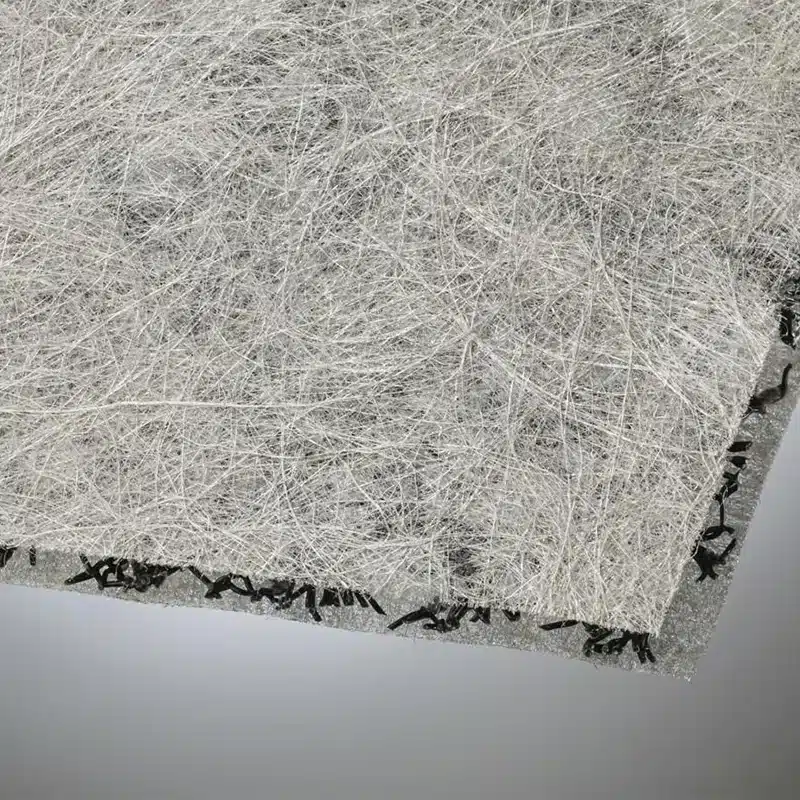

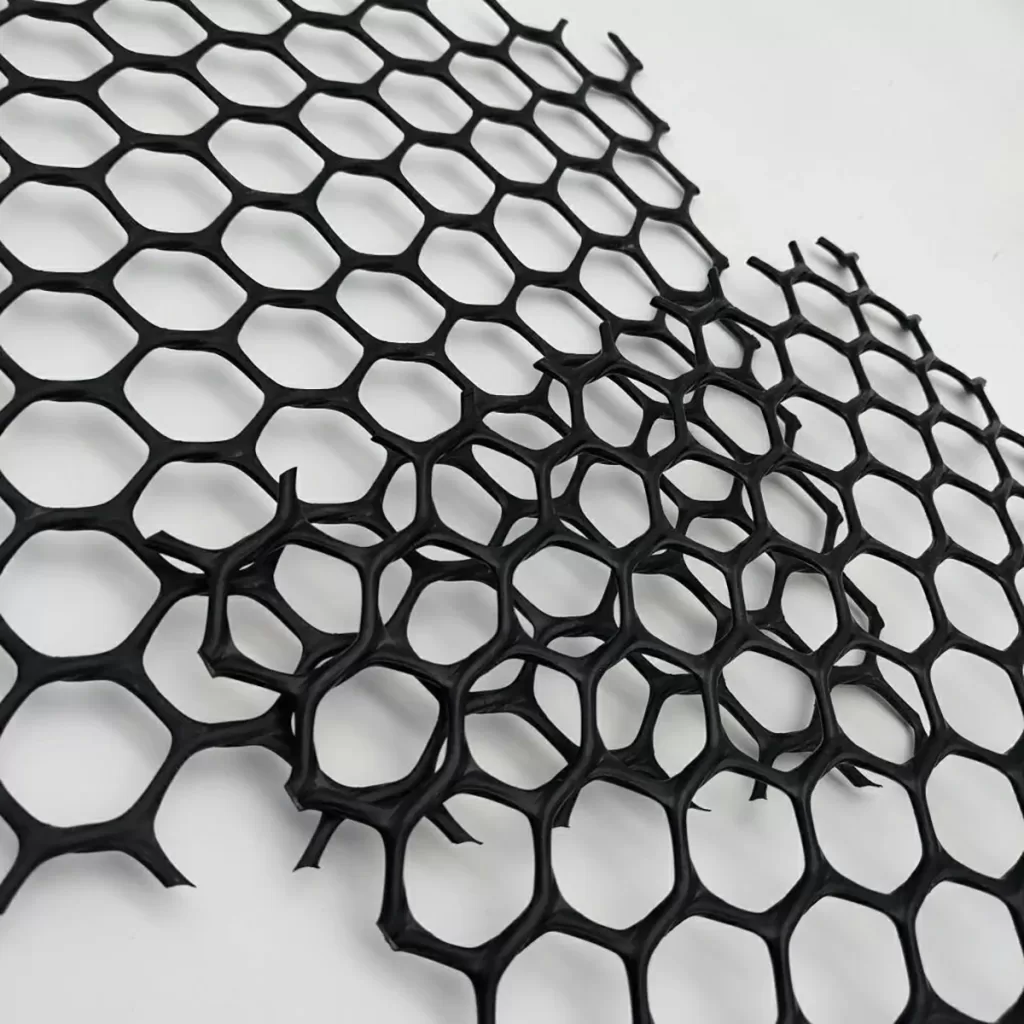

At Geofantex, we specialize in high-quality geosynthetics. Our portfolio includes Geotextiles, Geogrids, Geocells, Geomembranes, Geonets, Concrete Blankets, etc., which are exported to various countries worldwide, such as New Zealand, Canada, South America, Southeast Asia, South Africa, and Africa. This has enabled us to establish a strong presence in the market and forge successful partnerships with several industry leaders.

BLOG

Get Free Sample

We’ll respond as soon as possible(within 12 hours)