Miragrid 5XT Geogrid – 12′ x 150′ Roll – TenCate

$1,209.80

FREE SHIPPING

SKU MIRAFI-5XT-12X150

1 2 3 4 5 6 7 8 9 10+ Quantity

Quantity

Add to cart

Free Shipping – Please call (800) 748-5647 for pricing on larger quantities than listed below.

| Number of Units | Price Per Unit |

|---|---|

| 1+ | $1,209.80 |

| 2+ | $881.36 |

| 3+ | $782.34 |

| 10+ | $681.37 |

{} Share this:

Share on Facebook Tweet on Twitter Share on LinkedIn Pin on Pinterest

Miragrid 5XT Geogrid – 12′ x 150′ Roll – TenCate

Model: 5XT-12X150 Brand: TenCate Size: 12′ x 150′ Square Feet / Roll: 1,800 Geogrid Specifications: Download Miragrid 5XT Specification Sheet

Looking for a smaller roll size? We offer retaining wall geogrid in both 4′ and 6′ widths in addition to 12′. View Selection >

View our Full Selection of Geogrid >

Do you need a written quote? Submit a quote request >

This fabric is produced in the state of Georgia, USA and can meet Build America / Buy America (BABA) requirements when requested. If ordering this fabric for a BABA project be sure to indicate that a BABA fabric is required in the “order message” field on the cart page.

NOTE: Mirafi branded products are ineligible for return or order cancellation once the order has been shipped. If you would like to purchase an equivalent fabric which is eligible to be returned with a standard restocking fee please give us a call at (800) 748-5647.

This Product is Stocked in the California and Georgia Distribution Centers Only. FREE SHIPPING Require a written quote? Request Online > Questions? Call (800) 748-5647

PRODUCT SUMMARY

- High long-term design strengths (LTDS): Miragrid® geogrids have more than 220,000 hours of tension creep testing performed at an independent test laboratory.

- Credible: Dependable long term strength assured.

- Cost effective: Creep resistant polyester fibers provide higher allowable tensile strength, minimizing the required number of geogrid layers. Wide rolls significantly reducing placement time, lowering cost.

- Light weight: Easy to handle and no sharp edges.

- Flexible, tough: Minimizes movement of soil structure.

- Strength: Miragrid® geogrids provide the widest strength range, and are the highest strength geogrid material in the market today.

TenCate Miragrid® XT uniaxial geogrids function for: – Soil Reinforcement

YOUR TRUSTED MIRAFI SUPPLIER

- We are an authorized Mirafi / Tencate distributor.

- We only sell genuine Mirafi geogrid. We never ship mislabeled overruns or “knock-offs”.

- You order Mirafi, we ship Mirafi. Even if a stock issue arises we never substitute for another brand without the customer’s direct consent.

- Hate phone trees? So do we. When you call Paramount Materials you get a live person within a few rings, ready to help with product or order questions 5am – 5pm PST.

Fabric Shipping Time – Georgia Warehouse:

By default, Mirafi fabric orders ship from the Georgia warehouse where a full stock of the Mirafi fabric types are maintained. Most orders ship same day (M-F) if order is placed before 11:00 AM EST. Transit times displayed in the map are listed in business days, are approximate and are specific to the Mirafi fabric line. The day that the order is shipped is not counted as a transit day. Most Mirafi fabric rolls ship via LTL freight. For expedited shipping rates please call: (800) 748-5647 The transit times displayed on the map are for our free shipping option.

Fabric Shipping Time – Southern California Warehouse:

Note: By default, orders ship from the Georgia warehouse with the standard transit times shown above. If you would like your order to ship from the Southern California warehouse (Mira Loma) you must first fill out a stock check request. Orders can also be picked up at this warehouse location if preferred. Southern California warehouse orders must be placed over the phone. Most Mirafi fabric California warehouse orders ship same day (M-F) if order is placed before 11:00 AM EST. Transit times displayed in the map are listed in business days, are approximate and are specific to the Mirafi fabric line. The day that the order is shipped is not counted as a transit day. Most Mirafi fabric rolls ship via LTL freight. For expedited shipping rates please call: (800) 748-5647 The transit times displayed on the map are for our free shipping option.

PRODUCT INFORMATION

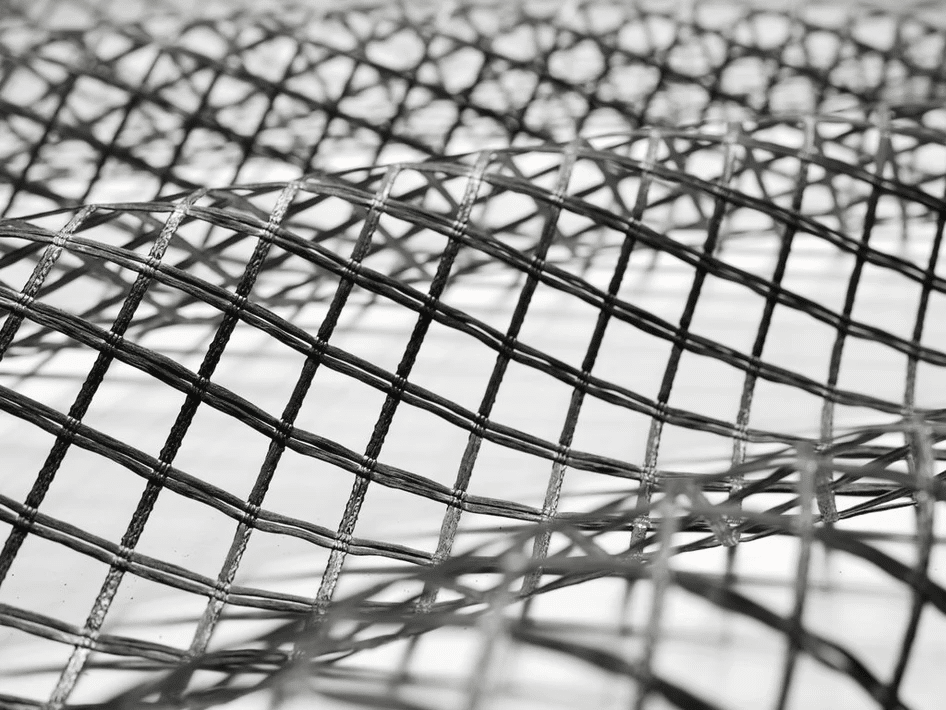

TENCATE MIRAGRID® XT UNIAXIAL GEOGRIDS: TenCate Miragrid® XT uniaxial geogrids are high performance woven polyester and polymer-coated geogrids used for soil reinforcement. TenCate Miragrid® XT uniaxial geogrids are used in Mechanically Stabilized Earth applications including internally reinforced walls, segmental retaining walls (SRW’s), and steepend slopes. TenCate Miragrid® XT uniaxial geogrids provide high, long-term design strengths (LTDS) and excellent soil interaction. TenCate Miragrid® XT uniaxial geogrids are constructed of high tenacity, high molecular weight, woven polyester to deliver long-term performance. The Difference TenCate Miragrid® XT uniaxial geogrids make: – Flexible and durable – Excellent creep resistance – High long-term design strengths – Lightweight and easily handled – Cost effective – Custom fabricated – System Solutions: Mechanically Stabilized Earth – Steepened Slopes: Vegetated and Wrapped Faced – Walls: Permanent and Temporary – Segmented Retaining Walls – Void Spanning – Veneer Reinforcement – Soil Reinforcement – Landfills

Downloads:

Product Description Sheet (MARV)

2XT Product Description Sheet

2XT Tri-fold

Engineered Structures Brochure

Mechanically Stabilized Earth Line Card

NTPEP Report REGEO-2011-01-001

NTPEP Report REGEO-2015-01-002

Technical Data Sheet PDF (MARV):

- XL

- 2XT

- 3XT

- 5XT

- 7XT

- 8XT

- 10XT

- 20XT

- 22XT

- 24XT

Case Studies:

- 2XT – Residential MSE/CMU Retaining Wall – Dacula, GA

- 2XT & 10XT – Greer Ranch – Murietta, CA

- 2XT & 24XT – Reinforced Soil Slope – Bennington, VT

- 3XT & 5XT – Soil Nailed Versa-Lok Retaining Wall – Toronto, Canada

- 5XT – Segmental Wall & Pavers – Minneapolis, MN

- 5XT – Reinforced Piled Embankment – Wat Nakon – In, Thailand

- 5XT – Anchor Wall – Botany Bay, Australia

- 5XT – McDonalds – Keystone Wall – St. Louis, MO

- 5XT – Segmental Wall & Pavers – Minneapolis, MN

- 5XT – Reinforced Wall – Keizer, OR

- 5XT – Welded Wire Wall – Burlington- Ontario, Canada

- 7XT – Reinforced Retaining Wall – Eagan, MN

- 8XT – Temporary Wire Wall – Key Largo, FL

- 10XT – Reinforced Slope – Charleston, WV

- 12XT – Landfill – Cumberland County, Shippensburg, PA

- 20XT – Geary Dike Levee Repair – Klamath Falls, OR

- Miragrid – Reinforced Steepened Slope – Hampton, PA

- Miragrid – Slope Reinforcement – Crystal Cove – Newport Coast, CA

- Miragrid – Mechanically Stabilized Slope – I495 – Lawrence, MA

- Miragrid – Steepened Slope – Home Depot – Statesville, NC

- Miragrid – Steepened Slope – I695, MD

- Miragrid – Reinforced Steep Slope – Edmonton, Alberta Canada

- Miragrid – Anchor Wall, Diamond Block – Corpus Christi, TX

- Miragrid – Metrolink – Keystone Wall – St. Louis, MO

- Miragrid – Keystone Wall – Woodstock, GA

- Miragrid – Versa-Lok Wall – LaCrosse County, WI

- Miragrid – SRW Reinforcement Wall – Living Zoo, CA

- Miragrid – ReCon Retaining Wall – Stillwater Mills, MN

- Miragrid – Geosynthetic Plantable Wall System – San Diego, CA 2006 IAA Award of Excellence

- Miragrid – Stress Relief Retaining Wall – Minneapolis Convention Center, MN

Miragrid XT

Show 10 15 25 50 100 entries

Search:

| PRODUCT | DIMENSIONS | SF/ROLL | SY/ROLL |

|---|

|

PRODUCT |

DIMENSIONS |

SF/ROLL |

SY/ROLL |

|---|---|---|---|

| 10XT | 12′ X 200′ | 2400 | 267 |

| 20XT | 12′ X 200′ | 2400 | 267 |

| 22XT | 12′ X 200′ | 2400 | 267 |

| 24XT | 12′ X 200′ | 2400 | 267 |

| 2XT | 12′ X 150′ | 1800 | 200 |

| 3XT | 12′ X 150′ | 1800 | 200 |

| 5XT | 12′ X 150′ | 1800 | 200 |

| 7XT | 12′ X 200′ | 2400 | 267 |

| 8XT | 12′ X 200′ | 2400 | 267 |

| Miramesh GR | 8′ X 150′ | 1200 | 134 |

| Miramesh TR | 8′ X 150′ | 1200 | 134 |

PreviousNext

All Mirafi Products

Show 10 25 50 100 entries

Search:

| PRODUCT | DIMENSIONS | SF /ROLL | SY /ROLL |

|---|

|

PRODUCT |

DIMENSIONS |

SF /ROLL |

SY /ROLL |

|---|---|---|---|

| 10XT | 12′ X 200′ | 2400 | 267 |

| 1100N | 15′ X 300′ | 4500 | 500 |

| 1100NC | 15′ X 300′ | 4500 | 500 |

| 1120N | 15′ X 300′ | 4500 | 500 |

| 1160N | 15′ X 150′ | 2250 | 250 |

| 1160N | 15′ X 300′ | 4500 | 500 |

| 135N | 12.5′ X 360′ | 4500 | 500 |

| 135N | 15′ X 360′ | 5400 | 600 |

| 140N | 12.5′ X 360′ | 4500 | 500 |

| 140N | 15′ X 360′ | 5400 | 600 |

| 140NC | 12.5′ X 360′ | 4500 | 500 |

| 140NC | 15′ X 360′ | 5400 | 600 |

| 140NL | 12.5′ X 360′ | 4500 | 500 |

| 140NL | 15′ X 360′ | 5400 | 600 |

| 140NLOrange | 15′ X 360′ | 5400 | 600 |

| 150N | 15′ X 300′ | 4500 | 500 |

| 160N | 12.5′ X 360′ | 4500 | 500 |

| 160N | 15′ X 300′ | 4500 | 500 |

| 160N Orange | 15′ X 300′ | 4500 | 500 |

| 170N | 15′ X 300′ | 4500 | 500 |

| 180N | 12.5′ X 360′ | 4500 | 500 |

| 180N | 15′ X 360′ | 5400 | 600 |

| 180N Orange | 15′ X 300′ | 4500 | 500 |

| 180NC | 15′ X 300′ | 4500 | 500 |

| 20XT | 12′ X 200′ | 2400 | 267 |

| 22XT | 12′ X 200′ | 2400 | 267 |

| 24XT | 12′ X 200′ | 2400 | 267 |

| 2XT | 12′ X 150′ | 1800 | 200 |

| 3XT | 12′ X 150′ | 1800 | 200 |

| 500X | 12.5′ X 432′ | 5400 | 600 |

| 500X | 15′ X 360′ | 5400 | 600 |

| 500X | 17.5′ X 309′ | 5400 | 600 |

| 550X | 12.5′ X 360′ | 4500 | 500 |

| 550X | 15′ X 300′ | 4500 | 500 |

| 550X | 17.5′ X 258′ | 4515 | 502 |

| 5XT | 12′ X 150′ | 1800 | 200 |

| 600X | 12.5′ X 360′ | 4500 | 500 |

| 600X | 15′ X 300′ | 4500 | 500 |

| 600X | 17.5′ X 258′ | 4515 | 502 |

| 7XT | 12′ X 200′ | 2400 | 267 |

| 8XT | 12′ X 200′ | 2400 | 267 |

| BXG110 | 12.9′ x 246′ | 3177 | 356 |

| BXG120 | 12.9′ x 164′ | 2133 | 237 |

| FW300 | 12.5′ X 300′ | 3750 | 417 |

| FW402 | 12.5′ X 300′ | 3750 | 417 |

| FW403 | 12.5′ X 300′ | 3750 | 417 |

| FW404 | 15′ X 300′ | 4500 | 500 |

| FW500 | 15′ X 300′ | 4500 | 500 |

| FW700 | 12′ X 300′ | 3600 | 400 |

| FW700 | 6′ X 300′ | 1800 | 200 |

| G100N | 4′ X 50′ | 200 | 22.2 |

| G100NC | 4′ X 50′ | 200 | 22.2 |

| G100W | 4′ X 50′ | 200 | 22.2 |

| G200N | 4′ X 50′ | 200 | 22.2 |

| H2Ri | 15′ x 300′ | 4500 | 500 |

| H2Ri | 17′ x 300′ | 5100 | 567 |

| HP270 | 12.5′ X 375 | 4687.5 | 521 |

| HP270 | 15′ X 300′ | 4500 | 500 |

| HP370 | 15′ X 300′ | 4500 | 500 |

| HP570 | 15′ X 300′ | 4500 | 500 |

| HP570 | 17′ X 265′ | 4500 | 500 |

| HP770 | 15′ X 300′ | 4500 | 500 |

| Miramesh GR | 8′ X 150′ | 1200 | 134 |

| Miramesh TR | 8′ X 150′ | 1200 | 134 |

| MPBBC1450 | 14′ X 300′ | 4203 | 467 |

| MPG100 | 12.5′ X 150′ | 1881 | 209 |

| MPG100 | 6.25′ X 300′ | 1881 | 209 |

| MPG4 | 12.5′ X 150′ | 1881 | 209 |

| MPM30 | 12.5′ X 360′ | 4500 | 500 |

| MPM50 | 12.5′ X 250′ | 3123 | 347 |

| MPV400 | 10.5′ X 360′ | 3780 | 420 |

| MPV400 | 12.5′ X 360′ | 4500 | 500 |

| MPV500 | 10.5′ X 360′ | 3780 | 420 |

| MPV500 | 12.5′ X 360′ | 4500 | 500 |

| MPV600 | 12.5′ X 360′ | 4500 | 500 |

| MPV700 | 12.5′ X 360′ | 4500 | 500 |

| MSCAPE | 3′ X 300′ | 900 | 100 |

| MSCAPE | 6′ X 300′ | 1800 | 200 |

| MSCAPE | 9′ X 300′ | 2700 | 300 |

| MTK 1′ W | 1′ X 200′ | 200 | 22.2 |

| MTK 2′ W | 2′ X 100′ | 200 | 22.2 |

| MTK 3′ W | 3′ X 50′ | 150 | 16.7 |

| RS280I | 15′ X 300′ | 4500 | 500 |

| RS280I | 17′ X 300′ | 5100 | 567 |

| RS380I | 15′ X 300′ | 4500 | 500 |

| RS380I | 17′ X 300 | 5100 | 567 |

| RS580I | 15′ X 300′ | 4500 | 500 |

| RS580I | 17′ X 300′ | 5100 | 567 |

| S1000 | 15′ X 300′ | 4500 | 500 |

| S1200 | 15′ X 300′ | 4500 | 500 |

| S1600 | 15′ X 300′ | 4500 | 500 |

| S600 | 15′ X 300′ | 4500 | 500 |

| S800 | 15′ X 300′ | 4500 | 500 |

| TM13C | 12′ X 75′ | 900 | 100 |

| TM14S | 12′ X 75′ | 900 | 100 |

PreviousNext

How Miragrid 5XT Is Used

Waste Management was needed to close a section of the Elk River Landfill, Phase 15 Cell, and apply a final geomembrane cover. To reduce the intrusion of the western landfill toe into a buffer area, the Landfill Operator or Owner needed a steep 40-foot high landfill side slope.

Gale Tec Engineering (USA) prepared a Value Engineering Change Proposal, or VECP, for the Contractor that would reduce the original project costs by effecting a geosynthetic reinforcement 1H:1V landfill side slope without hindering fundamental performances and characteristics of the project.

The project involved the construction of a steep 1H:1V landfill western slope at 40-feet above grade and the slope needed to support a new access road at the top of the landfill.

The Design

A soil reinforcement area defined by a slope of 1H:1V determined for the project. Due to both internal and global stability issues, the 1H: 1V slopes were designed and constructed with soil reinforcement.

A limit equilibrium computer program was brought in to assess the stability of circular and wedge failures within the reinforced slope sections. The global failures were designed based on the “target” factors of safety of 1.1 – 1.3 for temporary conditions and 1.4 – 1.5 for long-term conditions. The computer analysis performed searches to identify the most crucial failure surfaces as related to factors of safety. To provide both long-term and temporary stability to the slopes, geosynthetic fortifying layers were embedded into the newly constructed perimeter berm using granular fill.

Installation

The main reinforcement was achieved by installing TenCate Miragrid® 5XT and 7XT followed by installing Miragrid® 2XT as a secondary geogrid at 1-foot intervals between the main reinforcement layers. The main embedment lengths were 32 feet at the bottom of the berm and 28 feet at the top. For the reinforcement to work properly, the geogrid lengths needed to lie flat and taut. To make this happen, the fill was shoved out over the grid panels.

Erosion at the face of the reinforced slope was a major concern due to infiltration during storms. These storms could generate sloughs and slides in the near future. The following steps were applied to improve performance – 1 foot of topsoil, an erosion mat that was wrapped around the face, a MnDOT 50B seed mix with 12-12-12 slow-release fertilizer.