What is a geotextile tube?

A geotextile tube is an innovative engineering solution designed for various applications in environmental and hydraulic engineering. It is essentially a large, tubular bag made from permeable geotextile fabric. These tubes are filled with materials like sand, soil, or dredged sediments, and they serve multiple purposes, including erosion control, shoreline protection, and dewatering projects.

- Purpose: The primary purpose of geotextile tubes is to provide a cost-effective, environmentally friendly method for protecting and stabilizing shorelines, creating breakwaters, and managing sediments. They are also used in dewatering applications, where they allow water to filter out while retaining solids, thus concentrating the solid material for disposal or use in other applications.

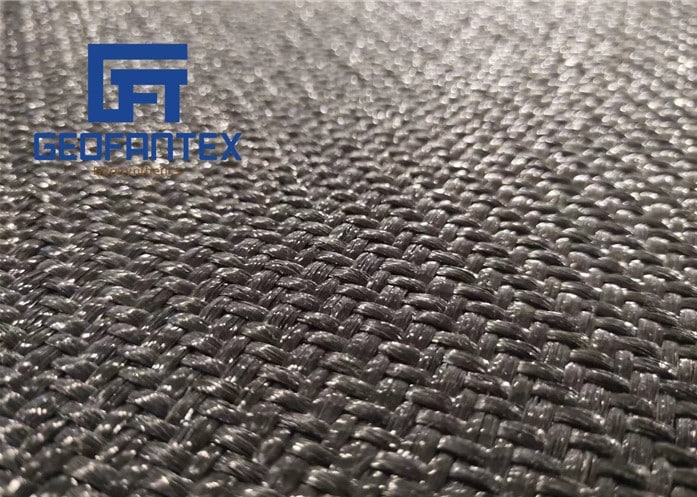

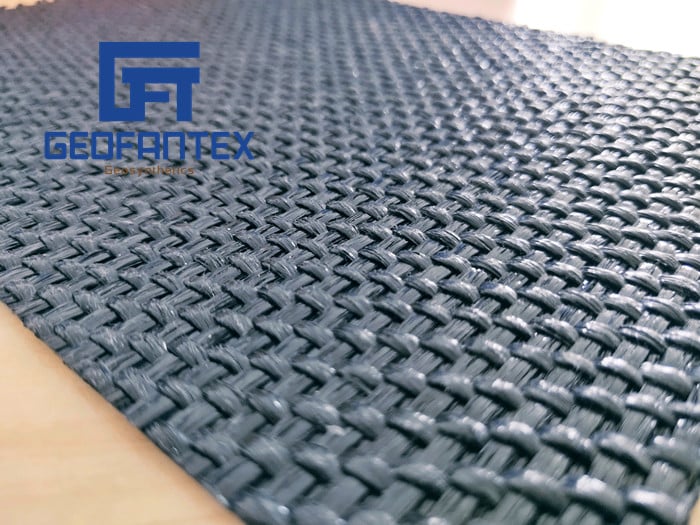

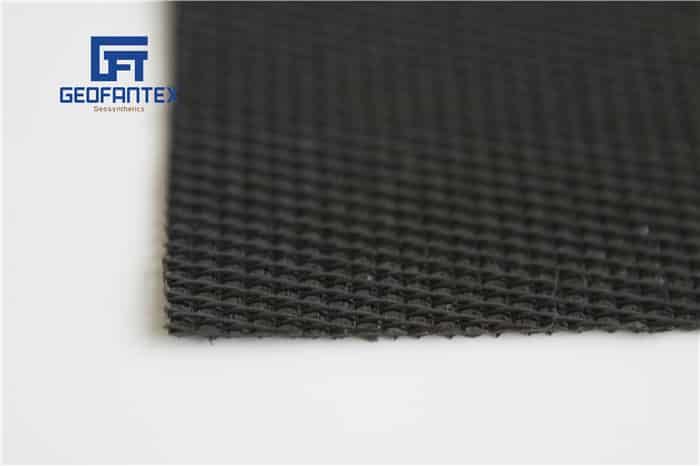

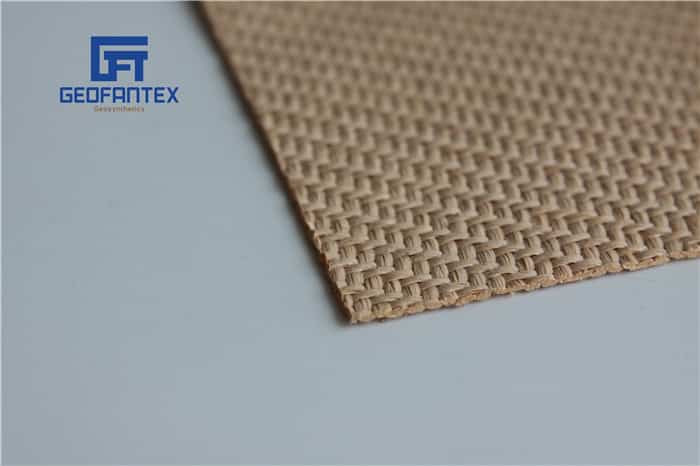

- Construction: Geotextile tubes are constructed from strong, durable, and permeable fabrics that can withstand the pressures of the materials they contain and the environmental conditions they are exposed to. The fabric’s permeability allows water to escape while retaining the solid particles, making them ideal for dewatering and sediment containment.

- Applications: These tubes are widely used in coastal and shoreline protection projects, where they act as barriers against erosion and help in land reclamation. In dewatering applications, they are used to treat wastewater, manage sludge from industrial or municipal sources, and control sediment in water bodies. Geotextile tubes are also employed in the construction of artificial islands, reefs, and underwater structures.

The versatility and effectiveness of geotextile tubes make them a preferred choice for engineers and environmentalists looking to solve complex problems related to water management, erosion control, and environmental restoration.

What materials can a geotextile tube dewater?

The list of materials that can be dewatered by geotextile tubes includes:

- Municipal water treatment and wastewater sludge

- Contaminated dredged material

- Marine dredgings

- Agricultural animal waste

- Fine-grained, inorganic industrial sludge

- Construction dewatering

- Shale fracking wastewater

POLYPROPYLENE MULTIFILAMENT WOVEN GEOTEXTILE – Geofantex

- Brand GeoFanTex® HWN

- Product origin China

- Delivery time 14-20 days

- Supply capacity 40′ HQ/ 14 Days

What are the advantages of geotextile tubes?

Advantages of Geotextile Tubes

Erosion Control

- Effective Barrier: Geotextile tubes act as a robust barrier against wave action, tidal changes, and water flow, reducing shoreline and riverbank erosion.

- Sediment Retention: They effectively trap sediments, preventing them from being washed away and promoting land reclamation.

Environmental Benefits

- Eco-friendly Materials: Made from environmentally friendly synthetic fibers, geotextile tubes minimize ecological impact.

- Habitat Creation: They provide a habitat for marine life by creating calm water zones where vegetation can establish and thrive.

Cost-Effective

- Lower Installation Costs: Compared to traditional methods like concrete structures, geotextile tubes are more economical to install.

- Reduced Maintenance: They require less maintenance over time, leading to cost savings in the long term.

Versatility

- Various Applications: Geotextile tubes are used in coastal protection, riverbank stabilization, dewatering of dredged materials, and wastewater treatment.

- Adaptability: They can be customized in size and shape to fit specific project requirements.

Durability and Strength

- High Tensile Strength: The synthetic fibers used in geotextile tubes provide high tensile strength, making them resistant to tears and punctures.

- Long Lifespan: These tubes are designed to withstand harsh environmental conditions, ensuring longevity and reliability.

Easy Installation

- Quick Deployment: Geotextile tubes can be quickly deployed and filled with dredged material or sand, speeding up project timelines.

- Minimal Equipment Required: Their installation does not require heavy machinery, making the process simpler and more efficient.

Improved Water Quality

- Filtration: Geotextile tubes filter out contaminants and fine particles from water, improving overall water quality in the surrounding area.

Can I stack geotextile tubes?

Stacking Process

- Foundation Preparation: Ensure the base surface is stable and level to support the weight of the tubes.

- Placement of Base Layer: Lay the first layer of geotextile tubes, ensuring they are properly filled and securely placed.

- Intermediate Layer Preparation: Add a geotextile layer or other material between the stacked layers to provide stability and prevent slippage.

- Placement of Subsequent Layers: Place additional layers of geotextile tubes on top, ensuring alignment and stability.

- Securing Layers: Use ties or other securing methods to connect layers and maintain the structure’s integrity.

Limitations and Considerations

- Weight and Stability: Ensure the underlying surface can support the weight of multiple layers.

- Material Quality: Use high-quality geotextile tubes designed for stacking to avoid failures.

- Environmental Factors: Consider the impact of environmental conditions, such as water flow, wave action, and soil type.

- Maintenance: Regular inspection and maintenance are required to ensure the long-term stability of the stacked structure.

Benefits

- Enhanced Protection: Stacking increases the height and provides better protection against high waves and floodwaters.

- Space Efficiency: Effective use of vertical space in limited areas.

- Customizability: Allows for tailored solutions to specific site conditions and project requirements.

Drawbacks

- Cost: Higher initial cost due to additional materials and labor.

- Complexity: Requires careful planning and engineering to ensure stability and effectiveness.

- Maintenance: Potential for higher maintenance needs due to environmental exposure.