This is a debate we are living each time we have to build internal roads on soils with a low (<5) to very low (<2) CBR.

Basically when the others alternatives (mainly soil substitution and soil improvement) are not feasible we are adopting two different solution, either a strong geotextile with reinforcement and separation properties or a geogrid (coupled with a thin geotextile used as a filter if necessary).

Presently both of them are working well, but only after many years we will know which one works best. I’m hearing very different opinion on the subject, so there is not an universal consensus.

As geotextile, both woven and nonwoven alternatives seem reasonable. Both of them provides separation of the aggregate from the subgrade and have high tensile strength and modulus, adding reinforcement to the foundation soil. Right now the woven solution is widely preferred.

As woven geotextile we have used the US250 from US Fabric, with the following properties:

| PROPERTY | TEST METHOD | ENGLISH | METRIC |

|---|---|---|---|

| Tensile Strength | ASTM D-4632 | 250 lbs | 1,112 N |

| Elongation @ Break | ASTM D-4632 | 15% | 15% |

| Mullen Burst | ASTM D-3786 | 450 psi | 3,102 kPa |

| Puncture Strength | ASTM D-4833 | 100 lbs | 445 N |

| CBR Puncture | ASTM D-6241 | 900 lbs | 4,005 N |

And as nonwoven, something like the US Fabric US 160NW looks like the best option:

| PROPERTY | TEST METHOD | ENGLISH | METRIC |

|---|---|---|---|

| Weight – Typical | ASTM D-5261 | 6.0 oz/sy | 203 g/sm |

| Tensile Strength | ASTM D-4632 | 160 lbs | 711 N |

| Elongation @ Break | ASTM D-4632 | 50% | 50% |

| Mullen Burst | ASTM D-3786 | 305 psi | 2,103 kPa |

| Puncture Strength | ASTM D-4833 | 90 lbs | 400 N |

| CBR Puncture | ASTM D-6241 | 410 lbs | 1,824 N |

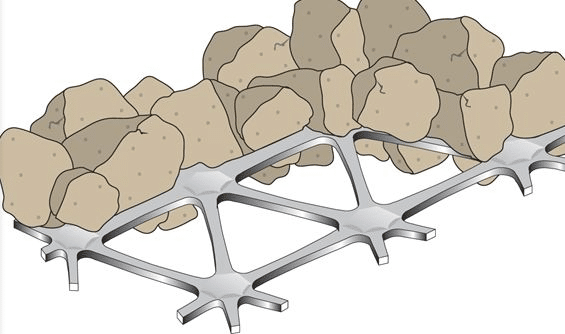

Regarding geogrid, it has been used in several wind farms all around Europe. I had a meeting with the representative from Tensar, and their product looks interesting.

It is a triangular net, providing support to the stone aggregate. It works equally well in every direction.

We have used it in Spain, and it have been used in several other projects in UK and Romania.

Previous Post

Next Post