HDPE Liners: What is the Life Expectancy of these Liners?

What is an HDPE Liner?

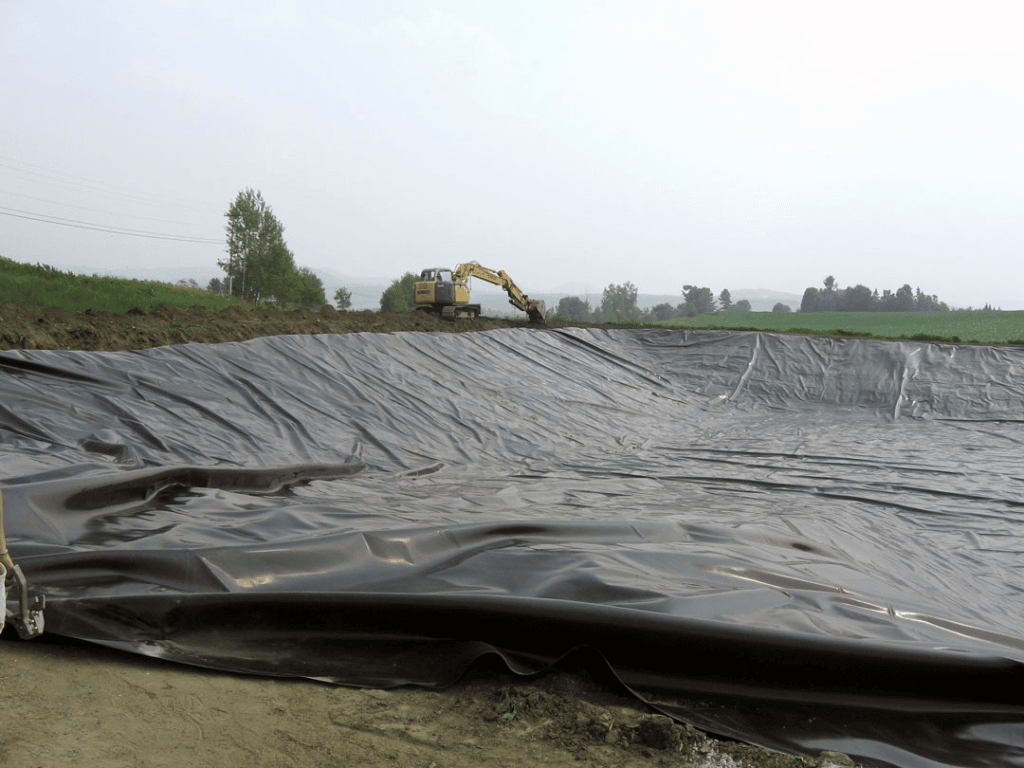

High-Density Polyethylene is one of the materials used to make heavy-duty liners and geomembranes. HDPEs are the thickest of liners with mil thicknesses from 20 mils up to 120 mils. HDPE liners are often used to line aquaponics, ponds, troughs, bioswales, canals, drainage, mud runners, slip-n-slides, and other water retention and containment applications. Other uses include root barrier, piping, and slip sheets.

Read 50 + Applications HDPE can be used in

What is the Life Expectancy of a HDPE Liner?

Geomembrane HDPE liners lasts the longest out of all synthetic liners. The life of the liner depends on many factors, most of them concerning the use of the liner and the condition of the environment. For example, a buried high-density liner can last hundreds of years in mild environments, but perhaps only several decades in weather conditions normally 100 degrees or hotter. Exposed liners have increased considerations. These are some of the common factors that affect HDPE liners: UV radiation, chemical degradation, oxidative degeneration, temperature, biology, the changing geography, and the morphology of the polymer.

Oxidative Degradation

The primary cause of geomembrane liner degradation is oxidation, which is either stifled or promoted based on the level of exposure to heat and UV radiation. Heavily exposed liners can reach their half-life in a matter of a few years. In stage one of oxidation, the antioxidants deplete; the second stage is the induction time, and the third stage is the time it takes for the liner to reach its half-life. Changing temperatures can cause liners to stretch and shrink, causing cracks and weak points making the liner more susceptible to damage. However, many covered liners might not reach their half-life for hundreds of years.

Chemical Degradation

HDPE liners display excellent chemical resistance properties, but hydrocarbon-based compounds can soften the liner over time since it is a petroleum-based material. Most containments are double-lined in case of chemical dissolution, but after decades of testing HDPE, chemical degredation doesn’t impact the integrity of the liner.

HDPE Liners are used in applications that rely on its ability to last a lifetime. Americover can custom fabricate your next liner and there is no minimum purhcase required. Get the size and mil thickness you need for your project. We also offer custom welding for drop-in liners.

Products Mentioned

| Learn more about Custom Fabricated HDPE Geomembrane Liner |

Trusted by Growers, Builders, and Distributors

Americover is the smart source for plastic and polyethylene sheeting. Trusted by contractors and distributors across construction and agriculture industries, our American-made products combine reliability with quality and innovation. As an Americover customer, you will receive the personalized support of a dedicated account manager to simplify the ordering process and ensure the best solution for every one of your projects. Our friendly, knowledgeable staff is here to answer your questions and fulfill orders Monday-Friday from 7 a.m. to 4:30 p.m. Pacific Standard Time. If you would like to speak with a representative, call us at 760-388-6294 or contact us.