Geotextile is one of the new materials of geosynthetics. It is a water-permeable geosynthetic material made of polyester or polypropylene through needle punching or weaving. The width of the geotextile is usually 4-6 meters. , The length is usually 50-100 meters. Both woven geotextile and non-woven filament geotextile belong to geotextile.

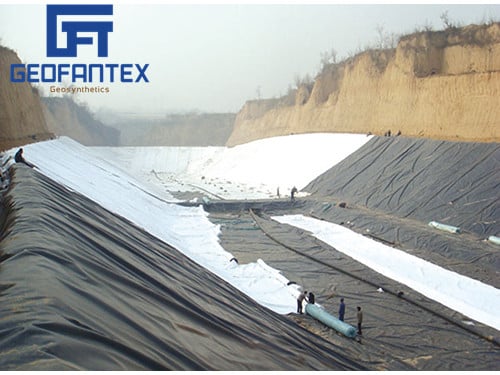

Geotextile Project

Features of geotextile:

- Whether it is dry or wet, geotextile can maintain great strength and elongation.

- Acid and alkali resistance, no matter it is acidic PH value or alkaline PH value, geotextile can be kept from being corroded.

- Geotextile has very good water permeability.

- Geotextile has good antibacterial performance, will not damage microorganisms and insects.

- The material of geotextile is softer and lighter, so it is faster and more convenient during construction.

- Complete specifications: The maximum width of the geotextile is 9 meters.

|

Nominal Breaking Strength KN/m |

4.5 |

7.5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

|

MD/CD Break Strength kN/m |

4.5 |

7.5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

|

Elongation At Break % |

40%-80% | ||||||||

|

CBR KN |

0.8 |

1.6 |

1.9 |

2.9 |

3.9 |

5.3 |

6.4 |

7.9 |

8.5 |

|

MD/CD Tearing Strength KN |

0.14 |

0.21 |

0.28 |

0.42 |

0.56 |

0.7 |

0.82 |

1.10 |

1.25 |

|

Thickness(mm) |

0.8 |

1.2 |

1.6 |

2.2 |

2.8 |

3.4 |

4.2 |

5.5 |

6.8 |

|

Unit Weight Tolerance % |

-5 | ||||||||

|

EOSØ90(Ø95), mm |

0.05-0.2 | ||||||||

|

Vertical Permeability Coefficient cm/s |

K×(10-1-10-3) K=1.0-9.9

| ||||||||

|

Width Deviation |

-0.5 |

Geotextile Project

Geotextile Price:

1.Geotextile Raw material price:

First of all, the price of geotextile raw materials will affect the price of geotextile. Polyester extracted from petroleum is the main raw material for the production of geotextiles. Thus, the price of oil will affect the geotextile price.

2. Geotextile Production process

The production process of polyester staple fiber needle-punched geotextile and polypropylene staple fiber needle-punched geotextile is a carding and needle punching process, which is simple; while polyester filament geotextile is a method of forming and consolidating polyester filaments Made. Different production processes will also lead to different types of geotextile prices.

3. Geotextile Specifications

Generally speaking, the wider the width and the higher the weight, the higher the price of the corresponding geotextile.

4. Geotextile Seasonal influence

When the winter is cold and the land is frozen when various projects cannot be constructed, the market demand for geotextiles will decrease, and the price of geotextiles will go down; the temperature is hot or the flood season, various water conservancy projects and flood control projects start, and the demand for geotextiles increases, Geotextile prices will also rise.

|

Geotextile Density |

Price Period |

|

100g/m2 |

$0.129-$0.151 |

|

200g/m2 |

$0.256-$0.311 |

|

300g/m2 |

$0.384-$0.421 |

|

400g/m2 |

$0.512-$0.622 |

|

500g/m2 |

$0.642-$0.752 |

Geotextile Packaging

Geotextiles are used in geotechnical engineerings such as power engineering, mining engineering, highway and railway, and water conservancy engineering.

Geotextile Welding

Geotextile production process:

According to different raw materials, non-woven geotextiles are divided into staple fiber needle-punched non-woven geotextiles and filament spunbond needle-punched non-woven geotextiles. The staple fiber needle-punched non-woven geotextile is made of polypropylene fiber and staple fiber polyester as raw materials. It is added to the bag opener to open the bag. After the bag is opened, it enters the opener to open; then it is sucked into the material box, and then squeezed and compacted to the calendar. Roll, stretch out the net, and then spread the net. Generally, 4 to 5 layers of net are laid, and then stretched by pre-needling, barbed, and main-needling processes, and trimmed; filament spunbond needle punched non-woven geotextile is Polyester chips are used as raw materials, melted and plasticized at high temperature, punched into a net, and consolidated by needle punching.

FAQ:

Q:What does geotextile mean?

A: Geotextile is a synthetic fiber with a high tensile strength that is usually used in civil engineering construction projects.

Q: Why do we use geotextile?

A: In many projects, such as landfills, road construction, etc., geotextiles can play a great role. It can protect water sources, land, etc. from erosion, help drainage and maintain soil stability.

Q: Does geotextile fabric stop weeds?

A: Geotextile can prevent the growth of weeds. Geotextile can keep the land moist and protect it from temperature changes. Therefore, the need for watering the plants is reduced, saving a lot of water costs.

Q: Does water go through geotextile?

A: Water flowing through the geotextile is the function of the geotextile:

- Geotextile can isolate building materials with different physical properties so that two or more materials are not lost, and the cloth is mixed to maintain the structure and function of the material, but the load-bearing capacity of the building is enhanced.

- Filtration function When water flows from low density to high-density soil layer, the good water permeability and air permeability of geotextile are used to make the water flow and intercept soil particles, fine sand, small stones, etc., and stabilize water and soil engineering!

- Water seepage effect, geotextile is good water pouring material, it can form a channel inside to discharge the excess liquid and gas in the soil structure!

Q: How to choose a suitable geotextile manufacturer from China?

A:

- Quantity and proportion of geotextile orders: The first thing to understand is of course whether the production capacity of Chinese geotextile suppliers can meet your geotextile order requirements. Our company has three production bases with a geotextile production capacity of 15 tons/day. Our goal is to become a world-class company dedicated to providing customers with comprehensive, reliable, and high-quality services and solutions.

- The delivery date of geotextile: when choosing a Chinese geotextile supplier, we must pay attention to the delivery date. Whether the delivery date can meet our waiting time for geotextiles. Our company has 3 production lines, which can completely solve the problem of delivery time, and deliver goods within 15 days at the latest.

- The quality of geotextile: The most important thing is to see whether the production equipment used by Chinese geotextile suppliers can meet the quality required by the geotextile project. Our clients’ projects involve 20 industries including environment (landfill, wastewater), aquaculture (fish and shrimp ponds), mine tailings, dams, oil and gas, canals, biogas, and water treatment. Thus, you can trust the quality of our company’s geotextile.