STEP 01

Planning The Geogrid Retaining Wall

- MagnumStone is available in 0 / 2.4 / 4.5 degree batter (setback) Check with your local producer for availability.

- Face textures vary from producer to producer. Please check with your local sales representative for more information and styles available.

- It is always recommended that a qualified engineering consultant be hired for all projects by the owner of the gravity retaining wall project.

- Soils test and analysis should be performed before design and excavation are performed. Understanding and utilising the correct soils information will help to determine the length depth of excavation and gravity retaining wall pieces.

Review

-

Mark the bottom and top of the geogrid retaining wall excavation location with spray paint or stakes

-

Establish proper elevation points for both the bottom and top of the wall before starting excavation

-

Organic Materials should not be used in any Backfill Zones

-

Store and protect good quality Backfill Materials from inclement weather during construction

STEP 02

Excavating The Geogrid Retaining Wall

Figure #1

Review

-

Excavate and prepare Sub Base Levelling Trench 6 to 8″ (15 to 20cm) below first course. This will be filled with a good 3/4″ road base material.

-

Figure 1 – The Leveling Pad Trench Depth should be cut out to approximately 6″ (15cm) from the back and and the front of the total depth of the base course. For instance, MagnumStone Standard Unit 24″ + 6″(front) + 6″(back) = 36″ total (61 cm + 15 cm + 15 cm = 91 cm)

-

Typical retaining wall burial depth or embedment Depth is 6″ to 12″ (15 to 30cm) Or 10% of the total height of the wall. Follow engineers cross section details or design parameters to ensure the correct embedment depth is being followed.

-

Excavate cut line to a 2 to 1 slope or greater. Check with local codes and regulations to ensure they are being followed correctly.

STEP 03

Sub Base and Base Stabilization Fabrics

Review

-

Compact Sub Base to 95% Standard Proctor Density or greater

-

Remove any Organic or poor soils in the Sub Base and replace with proper reinforced fill materials before compacting

-

(Optional) place 5′ to 6′ wide Base Stabilization Fabric on top of leveling pad trench

-

Base Stabilization Fabrics will help prevent sub base materials from mixing with the gravel base leveling pad during compaction

-

Fabric also provides extra Structural Bearing Stability to the base leveling pad

STEP 04

Compact Gravel Leveling Pad

Review

-

Typically a 3/4″ (20mm) road crush gravel or equivalent is used for the base leveling pad

-

Compact Gravel Leveling Pad to 95% Standard Proctor Density or greater

-

Correct Moisture Content in the gravel will help in reaching proper compaction

-

It is crucial that the base is level front to back and side to side. Any imperfections will be exaggerated as the wall goes taller

STEP 05

Laying First Course of MagnumStone Retaining Wall Blocks

Review

-

Place a steel stake at either end of the leveling pad to establish the back of the first course of units

-

Secure a tight string line to the stakes at either end which will provide the guide to line up the back of each MagnumStone™ base block

-

The distance of the string line between the steel stakes may vary due to heavy winds

-

MagnumStone™ base blocks, placed on the leveling pad, are manufactured without SecureLugs

-

Place each unit on top of the leveling pad in such a way as not to disturb the level gravel

STEP 06

Complete Base Row Installation

Review

-

Complete the first course of the MagnumStone geogrid retaining wall blocks

STEP 07

Backfill the Gravity Retaining Wall

Review

-

Backfill the MagnumStone blocks with an approved material. Run a plate vibratory compactor (for smaller lifts) or a roller / vibrating compactor over backfill materials with the proper moisture content.

-

Backfill in lifts or layers that are acceptable to the soils conditions and size of the compaction equipment.

-

Proper compaction is crucial to the success of the finished product.

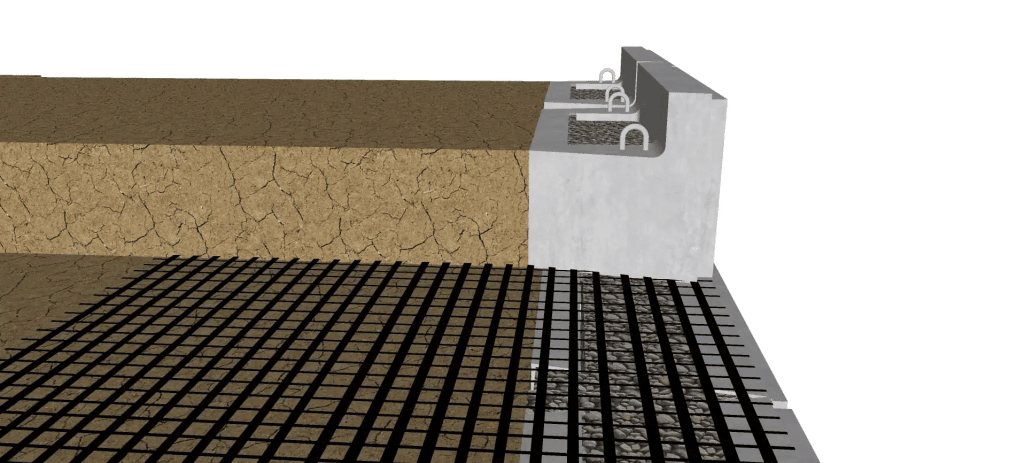

STEP 08

Drain Pipe for Geogrid Retaining Wall

Review

-

Drain Pipe should have adequate slope to drain water in the right direction towards each Drain Pipe Outlet

-

Drain Pipe Outlet can be every 30 or 50 feet

-

Perforated Drain Pipe, laid in the Horizontal Cores, can be a Sock Wrapped system to help prevent fines from migrating into the pipe

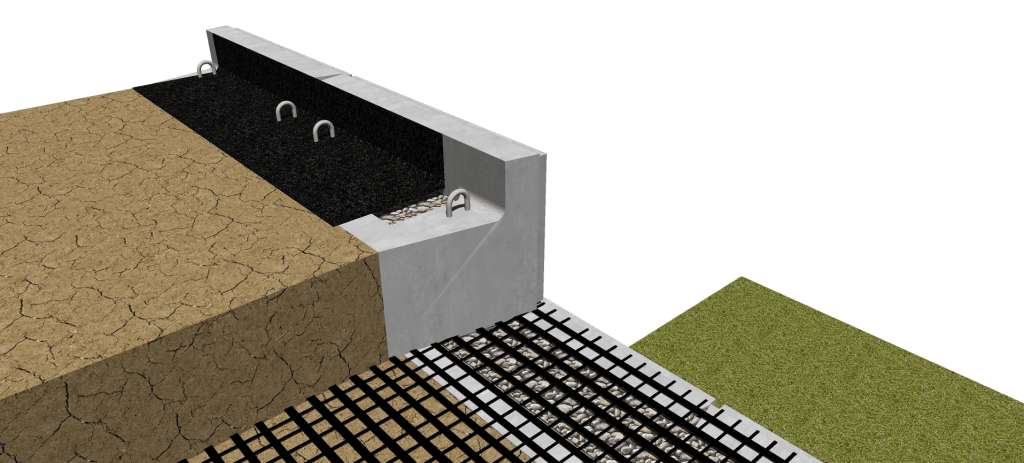

STEP 09

Installing Drain Gravel

Review

-

Clear Crush Drain Gravel is placed in the vertical and horizontal hollow cores after placing and compaction of the backfill materials

-

The Clear Crush Drain Gravel should be 2″ below the top of units to allow for SecureLug connection

-

Clear Crush Drain Gravel does not need to be compacted

-

Sweep the top of the MagnumStone™ Blocks clean of all rock and dirt before placing second course of MagnumStone™ Blocks

-

Make sure the Backfill Materials directly behind the wall are placed flush to the top of the units

-

Make sure the Backfill Materials are well compacted and level as possible

STEP 10

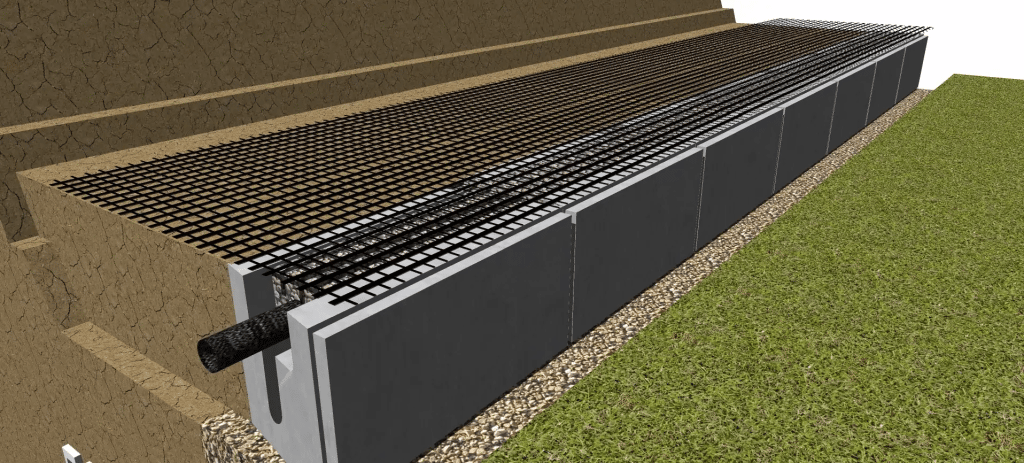

Installing Geogrids to Retaining Walls

Follow geogrid manufacturers guidelines and installation details for proper use

Review

-

Cut Geogrid Reinforcement to the length specified in the design. Each project has specific cross sections with lengths of geogrid shown.

-

Geogrids are manufactured in two directions Uni-axial or Bi-axial. Uni-axial grid has one direction of strength and that direction needs to be oriented perpendicularly to the face of the wall during installation. Bi-axial grid can be laid in two directions, perpendicular and lengthwise to the face of wall (ensure that the lengthwise direction is still in accordance to the length specified by the Engineer’s design)

-

Correct geogrid orientation, strength and length is crucial to the success of the wall project

-

Each Geogrid length should be laid parallel and adjacent to each other but never overlapping

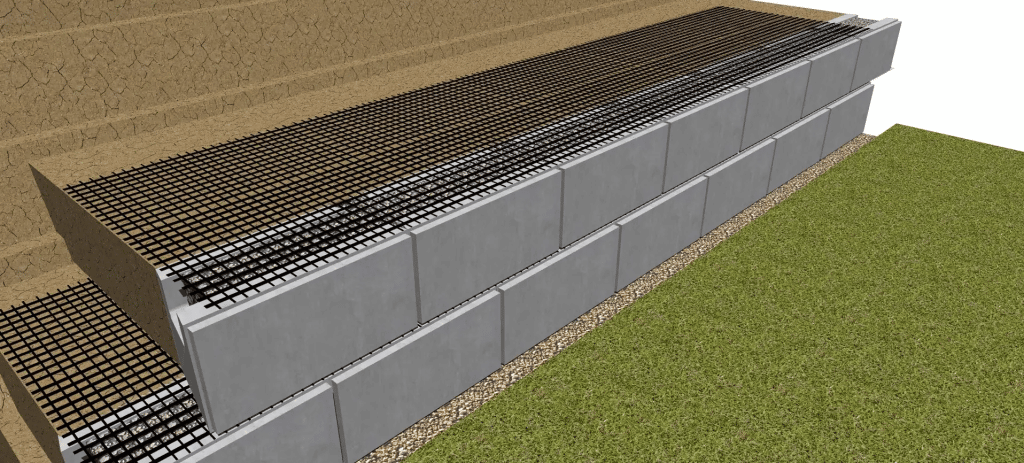

STEP 11

Geogrid and Connection with Second Layer

Review

-

Place the Geogrid as far forward on the MagnumStone™ units as possible without revealing it on the face

-

Place the next course of MagnumStone™ units on top of the lower units and Geogrid at a half bond to the lower units

-

The two SecureLugs will fit securely into the hollow cores of the two units below and lock the Geogrid into the gravel core

-

The gravel in the lower units will be recessed 2″ or more to allow for the SecureLugs connection

-

Complete the installation of units on the Geogrid Reinforced courses

-

Make sure each unit is installed against the unit next to it leaving no gaps between unit joints

-

Use stakes or backfill materials to maintain the tension of the Geogrid during backfilling

-

Do not drive equipment directly on top of Geogrid

STEP 12

Backfill Reinforced Geogrid Layers

Second Row Compaction for Retaining Wall

Second Row Drainage Gravel Installation for Retaining Wall

Second Row Geogrid Installation for Retaining Wall

Review

-

Backfill the Reinforced Zone by placing materials from the back of the wall towards the end of the Geogrid

-

Install drainage gravel in the cores after placing and compacting backfill materials

-

Install and compact backfill materials in Lifts no greater than 8″. Check with the compaction equipment for maximum lift details.

STEP 13

Backfill & Building your Geogrid Retaining Wall

Installing 3rd Row of MagnumStone retaining Wall Blocks

Compaction on 3rd Row of MagnumStone Blocks

Installed Geogrid on 3rd row of MagnumStone Blocks

Review

-

Install third row of blocks following the same guidelines as previous steps.

STEP 14

Backfill & Building your Geogrid Retaining Wall

Review

-

Install fourth row of MagnumStone Retaining Wall blocks following the same guidelines as previous steps.

STEP 15

Backfill & Building your Geogrid Retaining Wall

Review

-

Install third row of blocks following the same guidelines as previous steps.

STEP 16

Top of Wall Units

Review

-

Complete the top of the wall with MagnumStone™ Top Units

-

MagnumStone™ Top Units are manufactured with the back panel 8″ lower than the front face panel

-

The Clear Crush Drain Gravel and backfill materials will be placed flush to the top of lowered back panel. There are times when more than 8″ of top soils may be required.

STEP 17

Soil Separating Filter Fabrics

Review

-

Place a 6 ft wide Soil Separating Filter Fabric on top of the backfill and drainage gravel and against the back of the last units before placing the planting soils

-

The fabric will prevent planting soil fines from staining the face of the wall and migrating into the Clear Crush Drain Gravel (Angular Aggregate free of fines)

STEP 18

Final Grading of Geogrid Retaining Wall Installation

Review

-

Insure that final grading is done on top and bottom of the retaining wall

-

Make sure to protect newly placed planting soil from erosion during heavy rains or surface runoff