Geogrid For Gravel Roads

$1,046.63

FREE SHIPPING

SKU GGR-BXG110-13X246

1 2 3 4 5 6 7 8 9 10+ Quantity

Quantity

Add to cart

Free Shipping – Please call (800) 748-5647 for pricing on larger quantities than listed below.

| Number of Units | Price Per Unit |

|---|---|

| 1+ | $1,046.63 |

| 2+ | $788.55 |

| 3+ | $689.57 |

| 10+ | $648.20 |

View Retaining Wall Geogrid Selection > View Fabric For Beneath Gravel Roads >

{} Share this:

Share on Facebook Tweet on Twitter Share on LinkedIn Pin on Pinterest

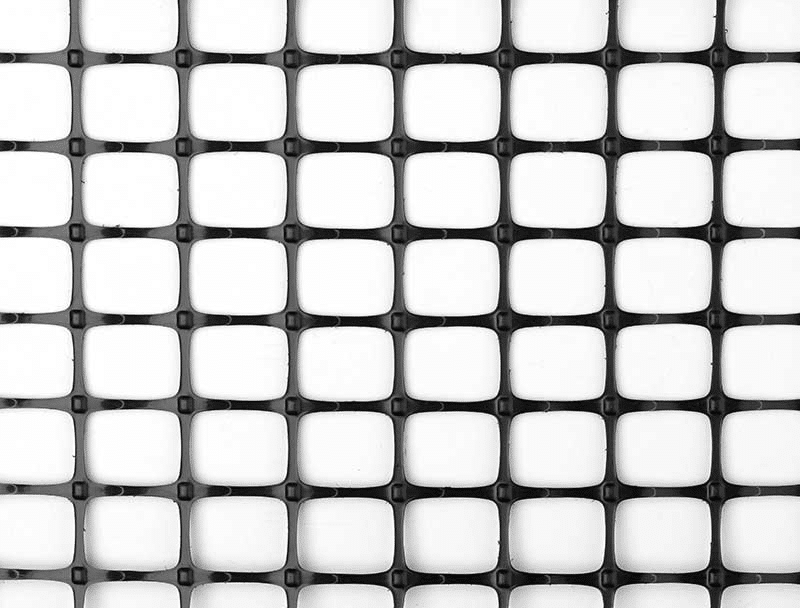

Designed for gravel roads, this geogrid material is the ideal product for reinforcing aggregate roads, driveways, and permanent gravel paths. This geogrid is placed beneath the gravel during construction to limit side-to-side gravel movement and helps support long-term use road use. Many municipalities and private construction contractors prefer biaxial geogrid because it reduces the amount of maintenance typically required to fill in potholes and standard wear and tear. The geogrid is made from durable punched polypropylene plastic and can be easily rolled into place for installation and cut if necessary to fit the project. Model: BXG110-13X246 Brand: TenCate Size: 12.9′ x 246′ Square Feet / Roll: 3,177 Geogrid Specifications: Download BXG110 Specification Sheet NOTE: Mirafi branded products are ineligible for return or order cancellation once the order has been shipped. If you would like to purchase an equivalent fabric which is eligible to be returned with a standard restocking fee please give us a call at (800) 748-5647.

This Product is Stocked in the California and Georgia Distribution Centers Only. FREE SHIPPING Require a written quote? Request Online > Questions? Call (800) 748-5647

PRODUCT SUMMARY

- Reinforcement Strength: High tensile modulus properties per ASTM D6637 for base reinforcement applications. For structures with dynamic short-term loadings, Mirafi® BXG geogrids offer high strength at low strain and are designed for maximum bearing capacity and shear resistance.

- True biaxial strengths: Mirafi ® BXG geogrids are biaxial grids that exhibit high tensile strength in both longitudinal and transverse directions, making them suitable for base course reinforcement and soil stabilization applications.

- Durability: Superior damage resistance from moderate to severe stress installations.

- Soil Interaction: Superior soil confinement resulting in greater load distribution. A combination of grid structure and polymers create optimum soil-grid interaction.

- Seams: Panels can be sewn together in the factory or field, providing cross-roll direction strength to facilitate installation

YOUR TRUSTED MIRAFI SUPPLIER

- We are an authorized Mirafi / Tencate distributor.

- We only sell genuine Mirafi geogrid. We never ship mislabeled overruns or “knock-offs”.

- You order Mirafi, we ship Mirafi. Even if a stock issue arises we never substitute for another brand without the customer’s direct consent.

- Hate phone trees? So do we. When you call Paramount Materials you get a live person within a few rings, ready to help with product or order questions 5am – 5pm PST.

Fabric Shipping Time – Georgia Warehouse:

By default, Mirafi fabric orders ship from the Georgia warehouse where a full stock of the Mirafi fabric types are maintained. Most orders ship same day (M-F) if order is placed before 11:00 AM EST. Transit times displayed in the map are listed in business days, are approximate and are specific to the Mirafi fabric line. The day that the order is shipped is not counted as a transit day. Most Mirafi fabric rolls ship via LTL freight. For expedited shipping rates please call: (800) 748-5647 The transit times displayed on the map are for our free shipping option.

Fabric Shipping Time – Southern California Warehouse:

Note: By default, orders ship from the Georgia warehouse with the standard transit times shown above. If you would like your order to ship from the Southern California warehouse (Mira Loma) you must first fill out a stock check request. Orders can also be picked up at this warehouse location if preferred. Southern California warehouse orders must be placed over the phone. Most Mirafi fabric California warehouse orders ship same day (M-F) if order is placed before 11:00 AM EST. Transit times displayed in the map are listed in business days, are approximate and are specific to the Mirafi fabric line. The day that the order is shipped is not counted as a transit day. Most Mirafi fabric rolls ship via LTL freight. For expedited shipping rates please call: (800) 748-5647 The transit times displayed on the map are for our free shipping option.

PRODUCT INFORMATION – TENCATE MIRAFI BXG GEOGRIDS:

APPLICATIONS Mirafi BXG geogrids deliver strength, long-term performance, reliability and quick installation for base reinforcement for paved roads, construction haul roads, foundation reinforcement, working platforms on weak subgrades, and secondary reinforcement for soil retaining structures. FUNCTIONS Confinement – The ability of a geosynthetic to restrain lateral movement from a soil or aggregate through friction or mechanical interlock. Soil Reinforcement – The synergistic improvement of a total system’s strength created by the introduction of a reinforcing geosynthetic (that is good in tension) into a soil and/or aggregate system (that is good in compression but poor in tension).

Downloads:

- Product Description Sheet

Geogrid Is The Answer To Prevent Structural Failure

Established construction companies are going out of their way to prevent structural failure and Geogrids have helped prevent this from happening due to their ability to help reinforce substrate.One of the best ways to gauge triaxial geogrid’s dependability is through its junction. Junction integrity is defined by something known as ultimate junction strength. Here’s a look at the term:

Ultimate Junction Strength Ultimate junction strength is the maximum amount of force a junction can withstand before breaking. The higher the junction strength means the greater the junction stability.There are two main reasons why triaxial geogrids are showing incredible junction stability.

- Ribs cross in two directions providing thicker junctions.

- Each junction is made of very dense polymeric materials.

These two reasons are why triaxial geogrid junctions stay intact over time.

Geogrid for Gravel Roads

Biaxial geogrids are geosynthetic materials constructed into a grid of integrally connected tensile components. The grid has open spaces of acceptable size to allow strike-through and will interlock with the surrounding aggregate such as rock. Biaxial geogrid increases the stiffness of unbound aggregate base layers and restricts the aggregate particles under repetitive stress.Biaxial geogrids are punched and drawn with polypropylene material and comply with Caltrans Standard Specifications for Biaxial Geogrids. The geogrid is placed either below or inside the aggregate base layer of a pavement structure. The composite space consisting of the geogrid and aggregate base is referred to as a mechanically stabilized layer or MSL

A typical asphalt biaxial geogrid application consists of:

- Hot Mix Asphalt

- Aggregate Base

- Prepared Subgrade

The Benefits of Biaxial Geogrid

Decreased aggregate base thickness for lower costs. Improved compaction and uniformity over soft soils. Less hauling and heavy truck traffic on local roads due to fewer materials needed for removal, replacement, or backfills. Can be used with recycled asphalt concrete aggregate base. Greater safety due to less construction time from less hauling and processing of subgrade or backfill materials.

Applications

Biaxial geogrids are meant for flexible asphalt pavements or gravel roadways. There are no reports regarding the benefits of using these geogrids under concrete pavement. Biaxial geogrids can be used in a variety of projects but will cost less in areas where pavement surface grade and drainage control are located.

Applicable Applications

For restricted pavement surface grades due to local drainage or vertical clearance. Biaxial geogrid offers a thinner base with a performance equal to the pavement with a thicker base. Accelerated construction is required. Thinner Biaxial geogrid will result in less construction due to fewer materials. Also, biaxial geogrid requires less compaction. An increase in pavement structural capacity and performance over time as a pavement without biaxial geogrid. Encountering soft or weak subgrade, biaxial geogrids can reduce or eliminate the level of materials that will have to be removed.

Summary

Most construction sites are now leaning toward geogrid to prevent structural failure due to its ability to withstand added stress and conditions from the elements.