Description:

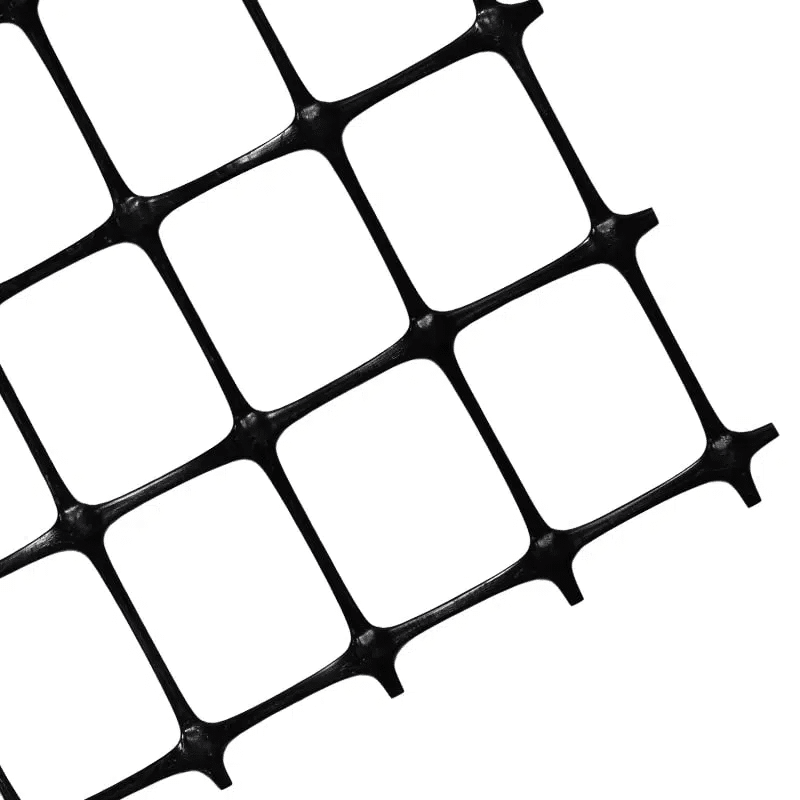

Cherokee Manufacturing offers a full line of punched and drawn polypropylene geogrids. Geogrids can be used in base reinforcement applications to reduce aggregate base, extend roadway life, and reduce construction timelines. Punched and drawn geogrids offer superior junction strength and efficiency, thus achieving a more reliable aggregate interlock and stabilizing subbase sections more efficiently.

| SKU | Description |

| GRID1100 | 13.1 ft x 246 ft |

| GRID1200 | 13.1 ft x 164 ft |

Commonly asked questions:

How deep should geogrid be?

For retaining walls take 10% of the wall height and bury it at that depth. For road stabilization, it is often a depth of 6″ to 12″. This is a general answer, always determine exact requirements from a civil engineer.

When should you use geogrid?

Geogrids can be used in base reinforcement applications to reduce aggregate base, extend roadway life, and reduce construction timelines. Geogrid can also be used for any retaining walls over 6 feet in height.

How is geogrid used as a soil reinforcement?

Geogrid interlocks with the soil or granular material placed on top of it. As force pushes down on the material above, the geogrid ribs stabilize the material below, ultimately confining it in place.

Can you overlap geogrid?

With retaining walls you should avoid overlapping geogrid without following proper procedures for overlapping materials. There must be at least 3 inches of soil between geogrid layers to avoid movement between geogrid materials. With road stabilization projects you can overlap geogrid to accommodate wider roadways but only overlap 1 to 2 feet. Also, make sure the bulldozer blade avoids catching that overlap/centerline by pushing the aggregate the correct way across the overlap. This is a general answer, always determine exact requirements from a civil engineer.