Driveway Fabric

Heavy-duty woven driveway fabric (also referred to as driveway matting) helps a gravel driveway resist ruts and potholes while significantly increasing time between resurfacing. For a very long lasting gravel driveway install our fabric with Ground Grid which greatly reduces gravel migration. When placed underneath asphalt or concrete driveway, the fabric helps to reduce cracking which extends the life of the driveway. Our selection of driveway fabric meets most DOT specs.

Building a Driveway with Driveway Fabric

Driveway fabric is an ideal material for building a driveway with a supportive base layer which will help to create a more stable surface which will resist ruts and potholes.

The Difference Between Woven and Non-Woven Fabrics:

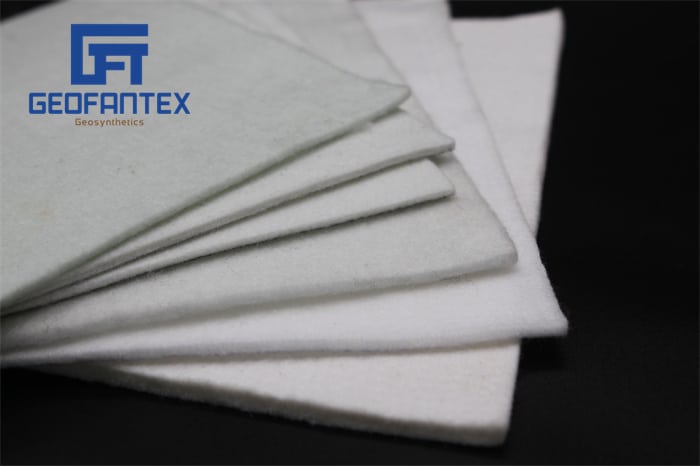

Woven fabrics allow for the passage of water where non-woven fabrics are filters; both serve different purposes. Our fabric is a woven stabilization fabric with high high durability. These fabrics offer a critical function that allows water to pass through and not damage your driveway. Non-woven fabrics, are often suggested, by some companies, but are not a good choice. Non-woven fabrics serve as a filter product and are not good for stabilization. Also, non-woven fabrics stretch more than woven fabrics, making them less attractive for driveway use.

Straightforward Application:

First, you must prepare the surface by removing any debris and protruding objects such as rocks and stumps that will tear the fabric. Next you are going to level the surface without creating a bathtub effect that could hold water. If you have an area that always retains water, use a pipe or drain to remove it.

Take the fabric and lay it directly on the now prepared surface. You do this by rolling it out flat, as you need to minimize any creases and folds. If needed, overlap the fabric by 1 to 3 inches and if needed, use pins or staples to hold the fabric in place. Using stones, dirt or other somewhat heavy materials will be enough to hold the fabric in place for dumping the aggregate (rock).

Apply the gravel in place and compact it in 6 to 8 inch lifts. If needed, dump trucks and/or loaders may be driven directly on the fabric without harm. However, avoid any quick stops, starts or turns. The proper method is to dump the stone onto the stabilized fabric then push it into the fabric for protection. You want to create a slight crown in order to provide water drainage on the driveway sides.

Fabric Under Asphalt

What Kind Of Rock (Aggregate) To Use:

The aggregate should be crushed and angular with a one inch diameter and 10% dust. Limestone is a good choice but other stone material will work just as well.

Some names of good stone quality are:

Dense Grade Aggregate (DGA) or

Crusher Run

Driveway fabric removes the need to use stones larger than one inch in size but do not use rounded stones.

Mistakes To Avoid Building A Gravel Driveway:

If you do not mind the extra care needed for a gravel driveway, the cost will be a lot less than paving and will last just as long. If building a gravel driveway is a first for you, there are mistakes you must avoid, so keep this information in mind:

Soft – Mushy Ground:

You do not want to spread gravel on a soft, mushy ground. Soil that has leaves, grass, roots, weeds and other debris will cause a spongy surface that will lead to trouble down the road. You must get rid of all topsoil and strip the soil all the way down to hard rock. This will make for a much more stable and dependable bed. You can place the topsoil somewhere for later use.

Poor Drainage:

If your driveway is not properly leveled, drainage is going to become a problem, allowing water to erode and destroy it. You will have nothing but a mud hole as silt, from below, comes up to the gravel. The silt will loosen the gravel pieces, they will lose their friction and start to weaken and separate.

Under these conditions your gravel will be a total and complete mess. To prevent this from happening, place a layer of Geotextile fabric between your subsoil and the bottom layer of gravel.

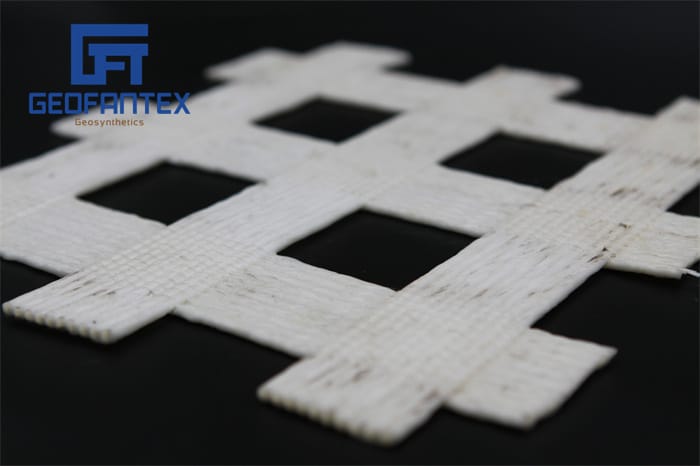

Keep the Gravel from Migrating:

One option to keeping the gravel in place on your drivewway is to use a gravel paver product which prohibits the gravel from migrating, resists rutting and provides a very stable surface. Gravel pavers are available in a variety of different shapes and sizes and are composed from either plastic or a heavy duty geotextile. Another option is to install sides to the driveway. The side forms can be constructed of wood or you could opt to place a retaining wall of brick or concrete blocks. These materials will also prevent spreading outside the parameters of the driveway.

Stay Away From The Wrong Size & Shape Of Gravel:

Your base layer of gravel pieces should be at least 3 to 4 inches in diameter or you will experience shifting and sinking from the weight of your vehicle on top of it. The pieces must be angular with sharp edges, rounded pieces are not capable of locking into place with adjacent pieces. Sharp-edged pieces are almost as solid as a single large rock. Gravel pieces laid on the final top layer should not be any larger than a golf ball. The total thickness of your driveway, with layers of different sizes of gravel, should be approximately 12-inches.

Each Layer Must Be Compacted:

While your driveway should be composed of various layers of gravel, each layer must be compacted. If not compacted properly, the driveway will not keep its shape. Each layer should be approximately 4-inches thick and the gravel pieces should be smaller than those of the layer below it. You must compact each layer as you lay them down by tamping with a hand operated roller or a machine.

If done properly, you will have a great driveway that will last for many years. Be careful not to overlook steps that must be taken. Building a driveway will take a little time and some work, doing a poor job will only lead to a complete mess that will have to be completely done over. Take each step one at a time, do not skip steps and make sure you have the proper materials required.

Driveway Fabric 101

As a homeowner, you have probably patched, paved, and performed other repairs to your driveway. There are times you feel like you spend half your life taking care of it. Of course, constant repairs come with a cost which is why many people have decided to go with gravel driveways. If you have chosen gravel, you should know everything you can about Landscape Fabric designed just for that purpose.

Some of the major benefits of laying landscape fabric under your gravel driveway, it allows for excellent drainage, keeps the gravel even, and prevents weeds from working their way through the gravel. On top of that, this fabric will increase the lifetime of your driveway at a minimal cost.

Aggregate Driveways have become very popular due to needing very little maintenance and the costs are much lower than asphalt or concrete. If this sounds good to you, then it’s time to find out about landscape fabric.

Why Should I put Landscape Fabric Under My Driveway?

If you want a gravel driveway that withstands wear and tear and is extremely stable, you need to place landscape fabric under the gravel. Even though gravel driveways have several layers of gravel, you still need landscape fabric under the first level.

Bringing Driveway fabric into building your driveway is actually quite easy to do and will make a world of difference! You also have several options to choose from to get the right fabric for your needs.

Do I Really Need Fabric For My Driveway?

Geotextile fabric will separate the rock layers from the gravel driveway from the soil below. When you decide to use this fabric, it will lengthen the life of the gravel and prevent rocks from sinking into the soil. Also, you will not have to constantly replace rocks over and over.

Gravel helps with drainage so it plays an important role in preventing water from seeping into areas where you do not want it to land, including nearby building foundations. Many runoff issues happen when using concrete or asphalt driveways but gravel driveways are well ahead of either.

You are welcome to use a regular landscape fabric but geotextile fabric is preferred because it’s stronger and a great deal more durable. Standard landscape fabric can be thin and feeble, which is usually the case with cheaper products.

A thinner fabric might be suitable but be aware it can easily tear when it comes in contact with rocks or even the tools you are using for the project.

How Does Landscape Fabric Work Under Gravel?

You might think laying down landscape fabric is not worth it because there does not seem to be much difference between the various fabrics compared to layers of rock. As reasonable as that sounds, you’d be wrong.

Landscape fabric plays an important part in creating your gravel driveway. It will withstand wear and tear caused by vehicles driving over it regularly. When installed properly, it will definitely increase its durability and provide a longer lifetime.

A geotextile or driveway fabric offers several purposes:

• Stabilization & Reinforcement

• Separation

• Filtration & Drainage

Stabilization & Reinforcement

Landscape or driveway fabric creates a separation that adds stabilization. Geotextile fabric offers high tensile strength so the fabric will stabilize the first layer of gravel that sits on top of it. In turn, it reinforces the entire structure of the gravel layers.

Without the use of landscape fabric, over time, the first rock layer will sink into the ground. The pressure on the driveway is concentrated on the sides of the cars. The rocks will start to sink unevenly into the ground. You will have to totally restructure the driveway instead of just revamping the top level.

Separation

One of the most important functions of landscape fabric is the separation of the ground from the layers of rock that forms the gravel driveway. This area is very important for keeping the driveway from sinking into the ground underneath.

The landscape fabric serves as a layer of separation that will prevent weeds from growing under the gravel driveway. This is very important around the edges of the driveway where there is far less gravel to keep weeds at bay.

Filtration & Drainage

It’s extremely important that gravel driveways have good drainage. If not, water will clog the driveway and cause many runoff issues. Landscape or geotextile fabric is created to allow water to flow through without causing erosion of the soil underneath.

Driveway fabric should provide enough absorbency to allow water to flow through without being so porous it will let soil out. The idea is to keep water from being retained while leaving behind the soil needed to keep the driveway level.

What Fabric Is Best For Driveways, Woven or Non-Woven?

For gravel driveways, the best choice is the woven landscape fabric. The non-woven fabric is good for filtration but not suitable for the passage of water.

Non-woven fabric does not have the bonding ability to create stability, though non-woven landscape fabrics have excellent value for certain projects. When it comes to gravel driveways, non-woven fabrics cannot match up to woven fabric. Also, non-woven landscape fabrics stretch a lot more than woven due to the lack of a tight weave needed for fabric strength

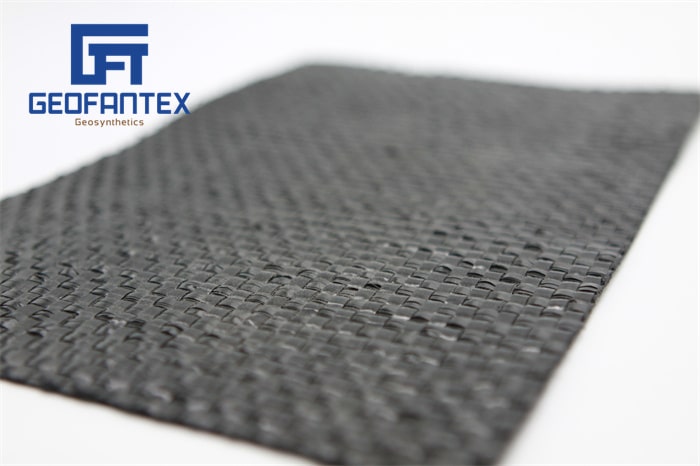

The Benefits Of Woven Landscape Fabric

Woven fabric offers excellent stabilization due to its woven fiber construction. The fabric will not stretch easily, allowing the gravel driveway to keep its original shape. This fabric ensures the subsoil underneath will be well covered.

Woven landscape fabric has a base layer that is strong, supportive, and very stable which is exactly what you want from a driveway fabric. Woven geotextile fabrics are a better choice than non-woven and traditional landscape fabrics for these reasons.

The Various Kinds Of Woven Landscape Fabric

Woven landscape fabrics are usually categorized with different grades. The average grades are standard, intermediate, and heavy-duty. Heavy-duty grade is generally used for commercial projects instead of residential driveways. The environmental surroundings where the driveway will be located will also have an influence over the kind of woven landscape fabric you should use.

Standard grade and intermediate grade geotextile fabrics are generally used for residential purposes. They are less expensive than heavy-duty landscape fabrics but these fabrics do not have the strength or drainage of heavy-duty.

Most residential gravel driveways do not need heavy-duty grade geotextile fabrics. On the other hand, if you live in an area where there is a great deal of rain and has poor draining soil, maybe heavy-duty would be what you need. All in all, the other grades are more than adequate for a residential driveway.

Below is a brief description of the Standard, Intermediate, and heavy-duty geotextile landscape fabrics:

Standard Grade Geotextile Fabric

The standard grade fabric is the most common woven landscape fabric for residential gravel driveways. The standard grade is a woven geotextile fabric that is single-layered. It is not particularly absorbent but is a good choice for dry areas or areas with low surface water.

This geotextile fabric is a good choice for separation. As this fabric works well in low surface water, it easily keeps soil from washing out.

Intermediate Grade Geotextile Fabric

Intermediate grade geotextile fabric provides a greater level of permeability water flow through and greater strength. This fabric is a tighter weave allowing for higher tensile strength.

You will observe a noticeable difference in the flow-through rate of this fabric and that it’s better for draining water.

The intermediate-grade driveway fabric is a good choice for residential gravel driveways as well as some commercial projects. This grade of fabric is a suitable choice for areas that have moderate rain and porous soil.

Heavy-Duty Grade Geotextile Fabric

As you can probably tell by the name, heavy-duty fabric is the most durable and strongest of the woven landscape fabrics. This driveway fabric has been designed with round and rectangular fibers woven into the fabric.

Heavy-duty geotextile fabric offers extremely high tensile strength and excellent drainage. Water passes through the heavy-duty landscape fabric very easily without the loss of the underlying soil.

Heavy-duty geotextile fabric is mainly used for commercial projects. This fabric is a good deal more expensive and typically is not the first choice for residential driveways. It’s primarily used for industrial projects that require a very strong material due to constant heavy traffic.

The Benefits Of Gravel Driveways

Affordability

The downside to installing a paved driveway such as asphalt or concrete, it’s a pretty big investment. You would need to bring in a professional to put down the concrete or asphalt which is going to end up costing you several thousands of dollars.

Unfortunately, it does not stop at that. Asphalt or concrete driveways need constant maintenance after construction which leads to higher costs. In most cases, the professional installer has to reseal the driveway every few years and the cost will add up.

If you choose a gravel driveway, there are many benefits. You do not have to hire a professional installer. The materials for a gravel driveway are a great deal cheaper and you do it yourself, saving a great deal of money on labor.

Minimal Maintenance With A Long Lasting Driveway

Gravel driveways last a very long time with very little maintenance. They do not degrade which will save on dealing with surface cracking that is normal with paved surfaces like concrete and asphalt.

By nature, gravel will move over time. The gravel does not move very much but typically the rocks will move off to the sides. As the gravel shifts, solving the problem is quite easy. Just re-level the top layer and add some more gravel if needed.

If you keep up with routine maintenance, the chances of having to completely redo the driveway will be slim to nil. The base layers can last for decades as long as you maintain the top layers.

Gravel Driveways Are Good For The Environment

Gravel driveways prevent runoff water that could form streams of debris that will run into the streets.

Because gravel is porous, it helps to prevent standing water from accumulating into puddles on the surface of the driveway. Water accumulating on a paved driveway will cause the water to move to a nearby area.

Also, with a paved driveway that runs close to your house or another building, water will drain into the weak areas of the foundation. Water seeping into the foundation will lead to structural damage. Because gravel is more porous, the water will drain to the right areas easily.

Learn How To Use Landscape Fabric

The first step in the project of constructing a gravel driveway is laying down the fabric. Because the geotextile fabric is so very important in the project, it’s important to know how to use the landscape fabric. In order to get any of the benefits depends on how well you have learned how to use the fabric correctly in order to finish the project the right way.

Performing each step properly will dictate whether your gravel driveway will work the way it’s intended to. The best way to go about it is to detail the steps for installing a gravel driveway. It won’t do any good if you know you need landscape fabric but have no idea how to work with it or how to put it in a gravel driveway.

How To Build A Gravel Driveway With Landscape Fabric

Actually installing the driveway is not difficult. You need some materials that you probably do not have hanging around but you can get them very easily.

The Needed Materials

Before starting your project, you must have all the right materials. How much material you will need will depend on the size of your driveway.

The Different Sizes of Gravel

Each layer of the gravel driveway will require different sizes of rock. Stay away from rounded rocks as they will easily shift away from each other. It’s strongly suggested you use angular rocks.

Tools

Get different rakes and shovels to spread the gravel. Purchase a tamp or leveler to compact the surface before you start installing the driveway.

If you need help, your home improvement center or store should be able to help you out.

Delivering The Gravel

You will have to hire a service to deliver the gravel to your location. It will take a large dump truck to bring the rocks to you and drop them along the length of the driveway. Count on more trips to deliver the different sizes of gravel.

Measure & Prepare The Driveway

You have to know the area of your driveway to ensure you have the right amount of fabric and gravel. Use markers that are visible and block the area that will become your driveway. If you are simply revamping your driveway, just measure the current dimensions.

Take the driveway and multiply the length by the width. It’s always a good idea to get a little more landscape fabric than the actual area of the driveway. You can overlap the fabric or if any of the fabric should rip.

Make sure the area is clear of all vegetation. If the ground is soft, you may have to remove a layer of topsoil. It’s important that you do not build a gravel driveway on soft or mushy ground.

Level The Ground & Lay Landscape Fabric

Once the ground is clear, it’s time to level the ground. If you are building a short driveway you can use a hand leveler but you’d be better off renting a leveler from the home improvement center.

The area for the driveway should be flat and level. Make sure you smooth out any bumps. Once everything is level, start to roll out the fabric. While laying out the fabric, you may need to place large rocks on the corners to prevent the fabric from being blown by the wind.

Use the pins and staples to secure the fabric to the ground. You can add pins according to each square yard of fabric or every three feet if you are only pinning the edges of the material.

Start Adding Gravel Layers

Once the fabric is in place, start adding layers of rock. The base gravel should be made up of large rocks. These rocks should be at least 4-inches in diameter and have rough edges. Have a dump truck drop off the gravel layer so you can spread it.

Be sure to tamp to compact the base layer before you start on the middle layer. Once compacted, the base layer of gravel should be at least 4-inches deep on top of the landscape fabric.

Repeat the process of spreading and tamping gravel for 2 more layers. The second, or middle layer, should have rocks around 2 to 3-inches in diameter. The top layer should have small, angular rocks. Each layer should be at least 4-inches deep once compacted.

As you will see, installing landscape fabric is a must for gravel driveway projects. Make sure you have woven geotextile fabric as average landscape fabric is too thin and can easily rip during installation.

Conclusion

More and more people are looking to build driveways and Driveway Fabric is a crucial component of a building something that will last the lifetime of your project.