Fabricated Geomembrane Panels

Save on Time and Costs

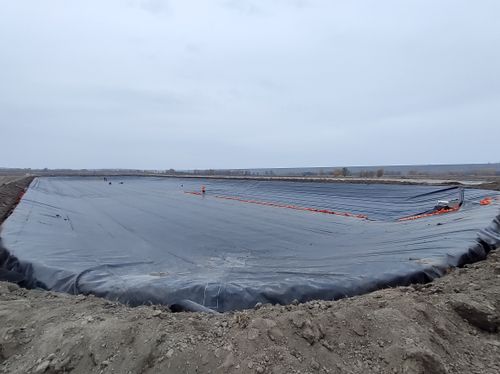

Save time and money on your lining project with Titan’s prefabricated geomembrane panels. Custom-fabricated to your specifications, these high-quality membranes eliminate on-site seaming and reduce installation time and costs. Made from durable materials that resist chemicals and environmental factors, they are ideal for a range of projects, including landfills, water features, and athletic field covers. Packaged for easy installation, these geomembranes offer the highest quality control standards in the industry.

Advantages

- Customized sizing

- No on-site seaming = time and cost savings!

- Folded and packaged for easy installation.

Common Applications

- Landfills liner

- Pond liner

- Floating cover

- Secondary containment system liner

- Water pit liner

- Mud pit liner

- Water feature liner

- Sports field liner and cover

Fabricated Geomembrane Institute

LESSONS LEARNED

Originally specified a 45RPP geomembrane for a project due to its UV resistance, puncture and tear strength, cold cracking resistance, and compatibility with fish rearing. However, due to supply chain issues, it was not available, so engineers substituted a 45 mil thick LLDPE geomembrane that shares similar properties and was available within the project timeframe.

HOW THE USE OF FABRICATION IMPROVED THIS PROJECT

The utilization of factory fabricated geomembranes and ballast tubes proved to be a crucial factor in the successful completion of the project, despite facing various obstacles. Originally scheduled for installation in August 2021, the project faced supply chain issues with the specified geomembrane, causing a delay until late October. Despite the limited welding hours due to the colder temperatures in Riverdale, North Dakota, the project was able to minimize field geomembrane seaming by utilizing large fabricated panels, enabling the crew to perform quality welding operations when optimal temperatures were reached. Additionally, the use of fabricated panels and ballast tubes played a vital role in mitigating the challenges posed by the strong North Dakota winds during late October, ensuring the safety of all crew members and allowing for efficient ballasting. Through the implementation of these measures, the project was completed with the highest quality standards, demonstrating the effectiveness of innovative solutions in overcoming complex obstacles.