geotextile thickness tester

Standards

According to GB/T 13761.1, ISO 9863-1, and ASTM D5199-01 test methods, the thickness of a single layer of geosynthetic material can be determined under specified pressure conditions. These test methods provide a precise means of measuring the thickness of geotextiles and other geosynthetic products. The test involves applying a specified pressure to the material and measuring the resulting thickness. This measurement is typically repeated multiple times to ensure accuracy and reliability of the results. The test method described in ASTM D5199-01 specifies the nominal thickness of the geosynthetic material, which refers to the thickness value assigned to the material for identification and classification purposes.

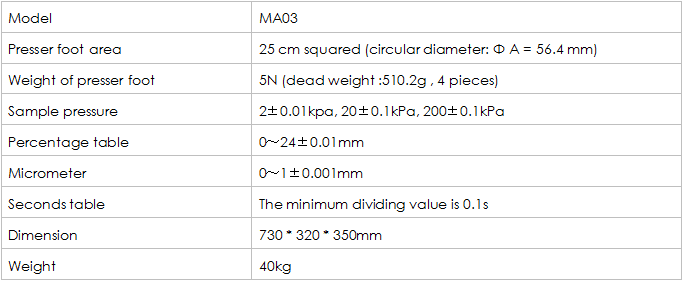

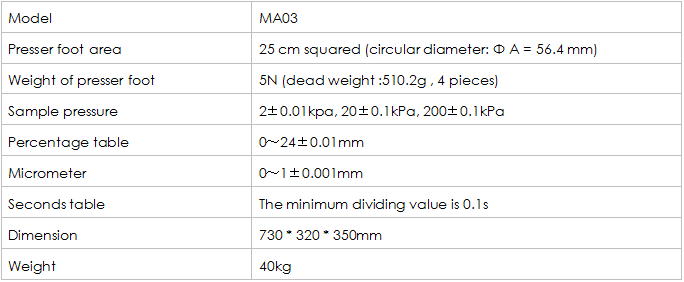

Key Specifications

geotextile fabric thickness

The thickness of geotextiles typically ranges from 0.25 to 7.5 mm, while the thickness of commonly used geomembranes today is 0.5 mm. It’s important to note that stiffness as a physical property refers to the flexibility of a material, and is not equivalent to the mechanical property of stiffness, which describes a material’s load-strain modulus.

1/8″ Thick Non-Woven Geotextile Fabric – 15′ x 300′ Roll

The 1/8″ thick (.115″) non-woven geotextile fabric is a heavy-duty material that serves as a separation layer between rock and soil, while also allowing water to pass through. These needle-punched non-woven fabrics are designed to be non-biodegradable, tear-resistant, and permeable with varying water flow rates.

This type of geotextile fabric has numerous applications, including use in drainage systems, as a separation layer under rip-rap, and in soil erosion prevention projects. The fabric’s ability to allow water to pass through while still providing separation makes it ideal for use in these applications.

In addition to the 1/8″ thickness, non-woven geotextile fabrics are available in thicknesses ranging from 3/32″ (.08) to 5/16″ (.32″). These varying thicknesses allow for customization based on specific project requirements.

Overall, non-woven geotextile fabrics are a versatile and durable solution for many construction and civil engineering projects. With their ability to provide separation and drainage capabilities, these fabrics are an essential component in many soil stabilization and erosion control applications.

Product Specifics

Drainage / Erosion

1/8″ (.115″) Thick Fabric

- Contractor Grade

- UV Resistant

- Non-Biodegradable

- Will Not Rot or Mildew

- Resistant to Rodent and Insect Damage

what thickness geotextile under ballasted roof

Ballast or protected flat roofs are primarily designed for smaller buildings with reinforced concrete construction. The characteristic cross-section of this roof includes a decline or cement screed on the decline, vapor barrier, thermal insulation (XPS or polyurethane foam), geotextile separation layer (except for TPO and FPO membranes), premium quality PVC, TPO or FPO ballast roofing membrane, drainage protective layer, and natural gravel.

l.The roof should have a minimum 1.5% decline to the basin level or ideally 2% decline, and thermal insulation should be a closed water-non absorbent structure. The ballast roofing membrane should be extremely resistant to chemical elements, bacteria, and algae, with a thickness of 1.5-2.0 mm and distinct ability for each welding. A honeycomb structure PVC protection and drainage layer with PP filter serves as mechanical protection and fast drainage.

Rounded edge gravel with a recommended thickness of 6 cm is used as a finishing layer. Ballast roofs used to have an advantage over exposed waterproofing membranes, but now they are mainly used for aesthetic reasons, strong winds, and easier installation. These roof systems are technically justified, economically advantageous, reliable, and easy to repair.