Best Solution to Asphalt Pavement – Fiberglass Geogrid

The best solution to asphalt pavement often lies in the integration of innovative technologies like fiberglass geogrid. Fiberglass geogrid is a new type of geosynthetic material made from fiberglass filament, employing a unique woven technique and coated with a special solution. This material boasts strong tension, capable of significantly increasing the bearing capacity of the ground and prolonging the service life of the road. With its high tensile strength and excellent wear-resistant performance, fiberglass geogrid is suitable for reinforcing soft soil, cement, concrete, asphalt, and more. Compared with steel plastic geogrid, fiberglass geogrid exhibits superior heat resistance and excellent thermal stability, performing admirably under high temperatures. Its inherent qualities enhance the structural integrity of asphalt pavements, effectively distributing loads, and mitigating issues such as cracking and rutting. The integration of fiberglass geogrid ensures smoother and safer roads, reducing maintenance costs and contributing to the overall well-being of communities. Its proven effectiveness solidifies its position as a cornerstone in modern pavement engineering, providing sustainable solutions for today’s transportation challenges.

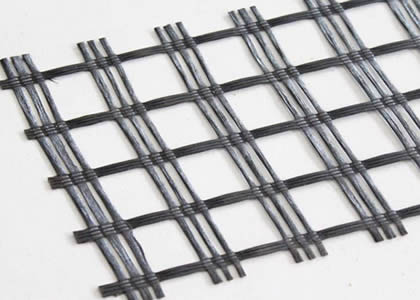

Fiberglass Geogrid for Asphalt Pavement Mesh, Asphalt reinforcement Mesh, Fiberglass Grid and Geotextile Drainage Composite, Road and Bridge Construction Material

Fiberglass geogrid stands at the forefront of modern infrastructure, a versatile marvel transforming the landscape of road and bridge construction. Engineered to reinforce asphalt pavements, it serves as the silent backbone ensuring durability and longevity. Its intricate mesh design intertwines seamlessly with asphalt, fortifying it against the relentless forces of nature and vehicular traffic. Fiberglass Geo Grid Net Fabric is a kind of earthwork-based engineering material that strengthens the road surface and roadbed, enhancing the structural integrity further. The coated fiberglass mesh geogrids possess the advantage of high tensile strength in the warp and weft directions, low elongation, excellent temperature range, and good anti-aging and alkali resistance, making them an ideal choice for asphalt pavement, concrete pavement, and roadbeds. Beyond mere reinforcement, the fiberglass grid extends its utility to geotextile drainage composite, orchestrating a symphony of functionality where water management meets structural stability. In the symposium of construction materials, fiberglass geogrid emerges as the silent yet indispensable conductor, orchestrating the harmonious fusion of strength and resilience. Additionally, plastic or PP geogrids are also available, offering further options for tailored solutions in construction projects.

Features

Effective and efficient solution for pavement improvement

ACEGrid®GA has a very high melting point exceeding 500 ° F to endure high temperatures during the asphalt layer construction process. Furthermore, the adhesive coating, bitumen, strengthens the bonding between fiberglass and asphalt, and the aperture size of ACEGrid® GA, 25.4 X 25.4 mm, provides an interlocking effect between the grid and asphalt course to increase its reinforcement performance. As a rolled and self-adhesive product, ACEGrid® GA is easy to install. Thus ACEGrid® GA is highly suitable for road construction, maintenance, and repair to reduce cracks and rutting.

Strong reinforcement in the long term

The fiberglass used for producing ACEGrid® GA has a very high modulus, which makes the geogrids have extremely low elongation and creep. Along with the adhesive surfaces and adequate aperture sizes beneficial for forming strong connections to asphalt layers, ACEGrid® GA can have high resistance to dynamic shock loading and seismic activity. Furthermore, the bitumen coating of ACEGrid® GA offers high resistance to abrasion, ultraviolet, weathering, bio-decomposition, and chemical corrosion. It can also effectively reinforce the asphalt layer in the long term.

Asphalt pavements are usually under the threat of cracking and degradation, and the repairs not only cost time and money but also influence traffic volume and safety. Therefore, for road pavement construction or rehabilitation, laying ACEGrid® GA in the asphalt layer is surely an economical choice. The benefits of using ACEGrid® GA include:

Asphalt Fiberglass Geogrid

Fiberglass geogrid is a new kind of favorable earthwork base material to strengthen the road surface and roadbed, which is composed of fiberglass filaments coated with an inorganic sizing agent. These fiberglass products possess the advantage of high tensile strength in the warp and weft directions, low elongation, excellent temperature range, and good anti-aging and alkali resistance. Fiberglass geogrid is extensively used for the reinforcement of asphalt pavement, concrete pavement, and roadbeds. Compared to traditional materials, fiberglass grids can reduce construction costs, extend road service, and prevent deflection cracks. Fiberglass geogrid can also be used to reinforce roadbeds in soft soil for railways, airfields immigration channels, and water dams.

Fiberglass geogrid has long-term structural stability. It is suitable for permanent projects. Fiberglass geogrid is extensively used in asphalt pavement, soil stabilization, and embankment reinforcement. It can effectively prevent the ground from cracking and subsiding. Applying this product can reduce the overlay thickness of asphalt, thereby, fiberglass geogrid can greatly reduce the construction cost and project investment.

- Material: Fiberglass yarns

- Color: Black

- Coating: Bitumen

- Elongation: 3% Max

- Length: 50m Width: 1-6m

- Certificate: CE /ISO9001/SGS

- Mesh Size: 12.7×12.7 25.4×25.4 40×40mm