Geogrid Fabric for Retaining Wall, Slope and Roadbase Support

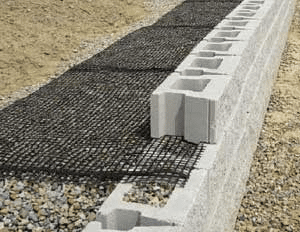

Retaining Wall Geogrid

(Universal & 3-9 Series)

Designed to help stabilize a retaining wall, retaining wall geogrid provides additional support to prevent wall collapse and movement. We offer both biaxial and uniaxial types which can be installed either perpendicular or parallel to the wall.

Various Sizes and Grades Available.

View Grid Options & Pricing

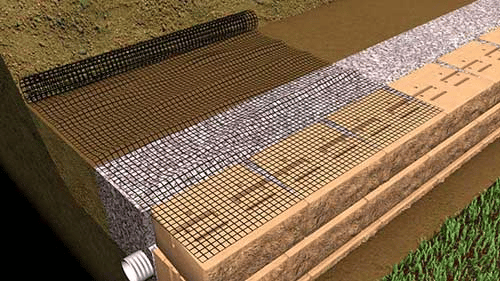

Road Base Geogrid

(Type 1 & Type 2)

Road base geogrid is designed to provide support to roadways and reduce the amount of base material required.

View Grid Options & Pricing

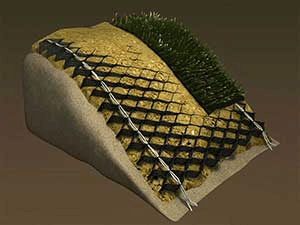

Slope Support Geogrid

(Geocells)

Although not technically a geogrid. Slope support geocells resemble a 3-D geogrid which is designed to protect a slope from erosion.

View Geocell Details & Pricing

Sort By: Price: Low to High Price: High to Low Most Popular Title Manufacturer Newest Oldest Availability

Go

40 per page 80 per page 160 per page 240 per page 400 per page Page of 1

Geogrid 3-Series, Soil Stabilization Grid 6′ x 50′

Price: $168.19

Geogrid 5-Series, Soil Stabilization Grid 6′ x 50′

Price: $216.45

Road Base Geogrid, Soil Stabilization Grid – Type 1 – 13.1′ x 246′ Roll

Price: $964.31

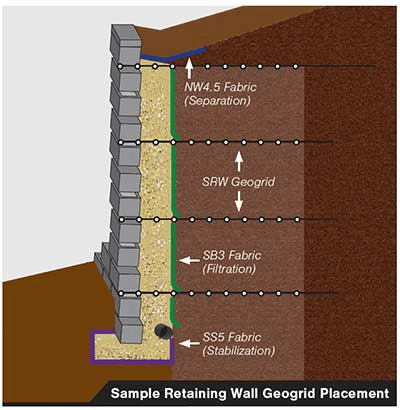

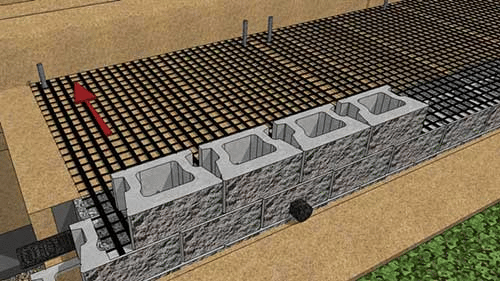

Geogrid in a Retaining Wall (click to enlarge diagram)

How to Build a Proper Retaining Wall with Geogrid Fabric (stabilizing grid):

Retaining walls play a very important role in protecting landscapes from natural elements. It is essential that the wall is constructed correctly using proper material to ensure long term stability. If corners are cut and stabilizing grid is not used the wall can lose stability and fall, endangering people and damaging the landscape. When hiring professionals to do the work, always check their experience in this area of construction.

There are several reasons why retaining walls fail. The most common being inadequate drainage behind the wall. With poor drainage, moisture circulates, freezes and thaws which can happen on a daily basis during the colder seasons. Some northern states experience this more often during Spring months and then again in the fall. With a clay back-fill, during the evenings freeze sets in and then ice starts melting and working its way deeper into the surrounding area and pushes outward.

In other cases, the walls are being forced to hold back more soil than they can handle. While in most cases this is caused by novices who really do not know how to properly construct a retaining wall, there have also been cases with landscapers, who should know better, doing the same thing.

If a retaining wall is built too high there will be no reinforcement to handle the force. Customers are spending thousands of dollars to build these retaining walls and then thousands more to tear them down and start all over again. Anyone can go search online about failing retaining walls and discover just how disastrous the outcome can be.

How A Good Retaining Wall Is Constructed:

A retaining wall is actually quite straight forward and the materials needed are not overly expensive. In order to construct the wall properly the process will require some additional digging, backfilling and compacting. The upside, its very inexpensive compared to the cost of having to start all over again.

Sadly, many people, in an effort to save time and cost, do not know about stabilizing grid and whether they even need it in their construction. In many cases, they will hire contractors who truly do not understand how a retaining wall actually operates or when stabilizing grid is needed. The money they end out saving, gets spent when the wall needs to come down and they have to start over.

Retaining wall reinforcement grid (stabilizing grid) from SRW is a woven fabric that is extremely strong. This fabric has high tensile strength and is pinned between the layers of the retaining wall. This extends into the soil the wall is retaining and locks the block or stone wall together with the soil behind.

When Is Stabilizing Grid Needed:

Determining wether stabilizing grid is needed for your wall will depend on the wall building material as well as they type of soil to be retained. Clay soils, for example swell when moist and retain water and thus are the hardest to retain. When clay soil is to be retained, stabilizing grid is highly recommended.

The material used for a retaining wall matters a great deal, the more massive the material is, the less stabilizing grid will need to be used. For example, most six inch or eight inch wide split face limestone walls, stabilizing grid should be considered if the exposed height is over 24”.

stabilizing grid is most desirable for man made walls with a height of 36” to 48”, depending on the design and size. If there is a slope at the base of the wall stabilizing grid should also be taken into consideration.

Once you have a wall that is over 6 ft in height, constructed with 24”or wider limestone or similar blocks and very dense material, stabilizing grid should be used.

Installing Different Geogrid Types (click to enlarge diagram)

Building the Retaining Wall:

Step One:

First you must excavate the soil area for reinforcement. All existing soils should be removed in order to have maximum embedment (or enclosed area) length for the stabilizing grid. There should be a good level soil condition behind the wall units in order to place each stabilizing grid layer.

Step Two:

You need to cut the stabilizing landscape geogrid (rated for retaining walls) in sections from the roll to a specific length (the embedment depth). The stabilizing grid should be rolled in the direction from the wall toward the embankment. You should always check the manufacturer’s specification for biaxial or uniaxial stabilizing grid. In most cases, the stabilizing grid is rolled perpendicular to the face of the wall.

Step Three:

You have to hook the stabilizing grid over the Keystone pins to ensure a positive operating connect between the unit and the stabilizing grid. Always be sure the stabilizing grid is placed within one inch of the wall’s face.

Step Four:

Secure the stabilizing grid by pulling the pinned stabilizing grid taut in order to eliminate any loose folds. Secure or stake the back edge of the grid before and during the back-filling and compaction. If desired, you can remove the stakes after the back-fill is in place. You can then place additional sections of grid, abutting each other, for a more continuous coverage for each layer.

Step Five:

Finally, you will place back-fill over the grid in 8 inch lifts. Give a minimum of 6 inches reinforcement fill cover before driving any equipment over the grid. Stay away from driving or turning any vehicles directly over the grid, this could cause excessive damage.

Uniaxial Geogrid: Physical Characteristics and Common Uses

Uniaxial geogrid retaining wall mesh is one of those products that you’ve likely benefitted from and probably haven’t realized it, either driven over or past without even noticing. Uniaxial geogrid is used in many structural building applications, but the question remains, though, what are uniaxial geogrids? Uniaxial Geogrids are lattice grid fabrics made of high strength composites or plastics such as high-density polyethylene or polypropylene. These strong plastic punched sheets are used to reinforce paved roads, or structurally support retaining walls. Geogrids are commonly used all around the world. They come in a few different styles and are made a handful of different ways. What Exactly is a Uniaxial Geogrid Material? As mentioned above, a geogrid can be made of very tightly woven polyester material with a polymer’s protective coating. The pattern of the geogrid is what makes it uniaxial. The uniaxial geogrid is stretched along the longitudinal direction. This makes the stress only transfer along the longitudinal axis. It also gives it a rectangle shape in the design. Geogrid should not be confused with geotextiles, which are:

-

Non-woven Fabrics (needle punched, or spun bond)

-

Woven Fabrics made from weavable plastic fibers

Where Is It Used? Geogrids are used in many different places that you drive by daily. Geogrid Reinforcing Fabric is used on:

Steep walls, steep hillsides, retaining walls, and many other vertical soil areas

-

If these areas are left unsupported, they could potentially lead to a hillside erosion

-

When landslides happen, the best case scenario the road is a little damaged; worst-case scenario, cars, houses, and lives could sadly be taken in the slide.

-

They are also used as sheet anchors by being inserted between geotextiles and geomembranes

As mentioned above:

-

Geotextiles = fabric

-

Geomembranes = Are used to contain liquids • Geogrids can be used on railways/railroads:

-

-

Railroads can become damaged and fail if the earth underneath gives way. This could lead to a derailment.

-

Trains are very heavy and will eventually wear down the earth below them.

-

With the added support, the railway can last much longer under the train’s heavyweight loads.

They are used on roads

-

Geogrids are also used in construction as an asphalt overlay.

-

Adding a geogrid under the asphalt will help spread out the weight of the asphalt across the dirt.

-

This helps support the ground from wearing down and creating dips in the road when vehicles pass over

-

It contains the earth but also prevents the asphalt from breaking away and settling into the dirt.

-

Utility companies

-

If you’ve ever driven past a scenery opening after utility companies have removed a significant number of trees (the trees’ roots typically help keep the ground intact), you have more than likely seen a geogrid.

-

After they are finished using the area, they are responsible for putting a geogrid in place to help stabilize the earth before adding new grass seed.

-

Geogrids work because they interlock with the fine material placed over them locking the material in place and preventing the aggregate from moving though the grid. This effectively creates a trapped solid layer that now acts like a solid block of material rather than individual rocks or grains of soil and provides stability to the layers underneath. The apertures allow the material to meet the covered soil, allowing the materials to interlock with the geogrid holes. This provides confinement of the underlying soil and safely prevents the soil/earth from shifting. Advantages of Using Geogrid Mesh There are many advantages of using geogrids such as:

-

Geogrids are a fairly inexpensive construction material compared to concrete retaining walls

-

They reduce the time it would take to finish the project

-

They will allow you to get better use out of your land by supporting steep hills and making the land more useable

-

It may seem like a simple design and even feel flimsy to the touch. This is intentional. Because of the flexibility, it can mold easily to the ground, which can be very uneven.

During an earthquake, it is far less likely to break or allow the land to give way.

-

It will move with the ground and help prevent the soil from loosening and causing damage.

-

-

They keep you safe from any debris falling when used as retaining walls.

They don’t block the grass.

-

You won’t have to worry about seeing a hillside of only dirt.

-

The grass will grow just fine (after grass seeds are put down), leaving a nice sturdy hill.

-

Different Geogrid Patterns There are typically three different patterns used when speaking about geogrids. These patterns are:

Uniaxial Geogrid – Also referred to as mono – oriented geogrids.

-

As mentioned above, a uniaxial is stretched along the longitudinal direction.

-

Simply put, the pattern is more of a long oval or rectangle shape pattern.

-

-

This makes the stress transfer only along the axis, giving it far higher strength in one direction over the other.

Biaxial Geogrid – Also known as bi-oriented geogrids. This pattern is stretched along both longitudinal and transverse directions.

-

This design is more of a square shape.

-

The stress is equally transferred in both directions.

-

These are typically used in construction due to the equal strength running along both axis’s

-

-

Triaxial Geogrid – This is a newer pattern in the geogrid world.

-

This pattern also has the weight stretched in all directions

-

This pattern resembles diamonds or triangles.

Different Ways Geogrids are Manufactured There are three different ways that geogrids are manufactured. Depending on the way it is manufactured will change the look and feel of the grid. These are the different ways geogrids can be manufactured:

-

Woven Geogrid – These are as simple as they sound. These are made from a very tightly woven polyester material with a protective coating of polymer on it.

-

Bonded Geogrid – These are made by bonding at right angles. Two or more sets of strands or other elements are typically used to form this bond.

-

Extruded Geogrid – These geogrids are made of extruded polymers. The uniaxial or biaxial polymers are stretched to create an extruded integral structure. This pattern is far less flexible than other types.