Oustanding Flexibility

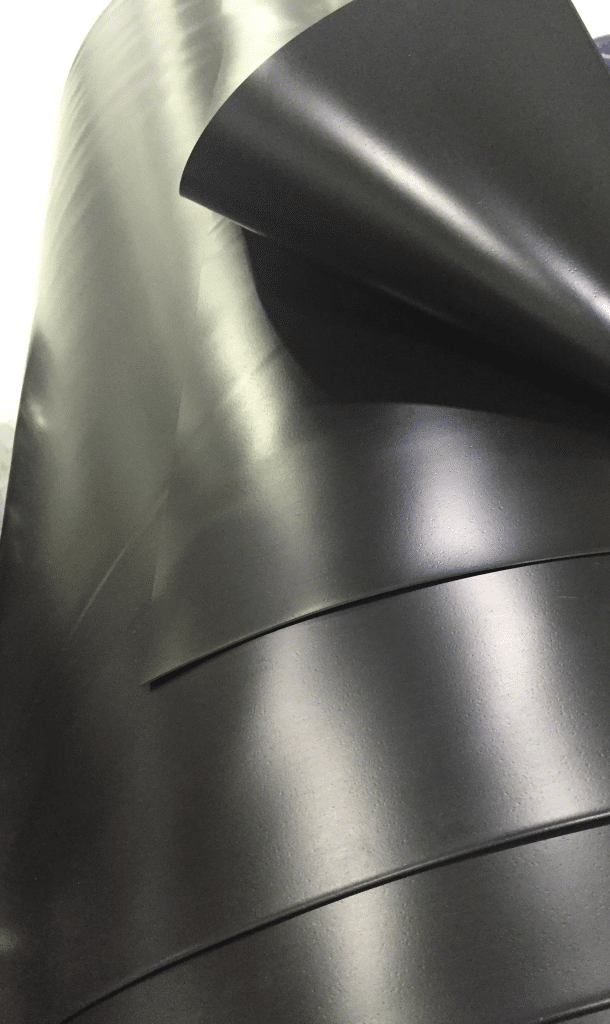

Polypropylene (PP) styles combine outstanding flexibility, elongation, cold temperature resistance, long-term UV stability, and advanced chemical resistance. Unsupported Polypropylene (PP) is manufactured without the reinforcing scrim found in supported styles. The unsupported styles of PP are some of the most flexible materials available for use as a fabricated geomembrane, making detail work such as attaching to structures or creating corners an easy task. PP can be installed and welded in the coldest conditions having been installed in temperatures as low as -50 C (-58 F). Upon request, an NSF/ANSI Standard 61 certified PP Geomembrane is also offered; please contact us for further details.

Unsupported PP is a clear choice for water and water-based effluent storage when the liner will be left exposed. PP has quickly become a favorite with many of our customers who require a flexible prefabricated liner to provide tough, resilient containment. On your next water containment project, PP’s unique blend of properties and performance may be just what you are looking for.

Benefits of Polypropylene:

- Flexibility

- Resistance to low temperatures

- Long term UV stability

Typical Applications:

- Coal Mining

- Floating Covers

- Lagoons

- Ponds

- Potable Water

- Reservoirs

- Bioswales

Product Specifications:

- 40 Mil Specification

Each and every liner panel produced is a custom panel. The way we set up our shop is unique in that our shop welders produce prefabricated panels to best match your containment area. We size each panel to fit, without waste, in a logical sequence in your containment area. In containments with irregular shapes, we size our panels to best accommodate the irregular size.

| POLYPROPYLENE FABRICATION SIZES | ||

| Material Style | 3000 lb Panel size 1400 kg | 4000 lb Panel size 1800 kg |

| PP 20 mil (U) Unsupported | 30,000 ft2 2,800 m2 | 40,000 ft2 3,700 m2 |

| PP 30 mil (U) Unsupported | 20,000 ft2 1,900 m2 | 26,500 ft2 2,500 m2 |

| PP 40 mil (U) Unsupported | 15,000 ft2 1,400 m2 | 20,000 ft2 1,900 m2 |

There are no theoretical limits to the size of the liner panels that we can prefabricate but there are some practical limits, notably panel weight. Panel weight is important because of the limits of handling equipment that will be available in the field. If a forklift or other piece of equipment is available for placement and deployment then a panel up to 1800 kg (4000 lbs) could be used. If only “hand power” is available for deployment then a panel weight of 1400 kg (3000 lbs) should not be exceeded. Under certain circumstances, larger panels can be provided. Please contact your EPI Representative for further details.

EPI utilizes hot wedge fusion welding for the fabrication of unsupported PP materials. This welding technique produces welds with full Film Tear Bonds.

Panels are accordions folded in one direction and then rolled in the other direction. Unfolding instructions and dimensions are marked on the individual liner panel. Each panel is wrapped in an opaque, weather-resistant covering suitable for shipment and storage at the site.