Stabilization Fabric – Woven

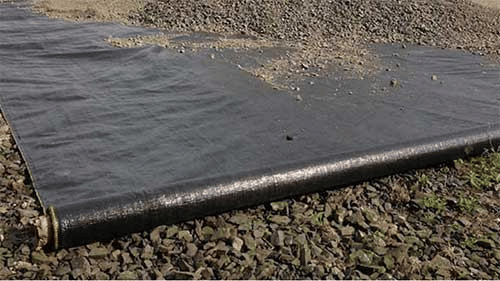

Woven geotextile fabric also known as stabilization or driveway underlayment plays an essential role in building a strong separation layer between the subgrade soil and the base layer which cars and trucks are able to drive on. The following fabrics are classified by grade from Standard to Intermediate then finally to Heavy Duty Grade. Each of these vary in their technical specifications of strength and permeability and subsequently which applications for which they are best suited.

- Woven geotextile provides excellent base support for roadways, parking lots, paver patios, and driveways.

- Reduces the amount of base materials required for the project

- Excellent puncture and tear resistance

- Meets most DOT specs

Standard Grade Woven Stabilization Fabric

Woven stabilization fabrics are ideal for separating the subgrade soil from the aggregate base layer. This is a very popular type of geotextile that has been specified for use by…

More

Intermediate Grade Woven Stabilization Fabric

Intermediate grade woven stabilization fabric is a higher tensile strength permeable geotextile. Perfect for projects where it is essential that water is able to flow through the fabric and into…

More

Heavy Duty Grade Woven Stabilization Fabric

Heavy duty grade woven stabilization fabric provides ultra-high tensile strength at low strain rates to increase project performance and life. This grade of fabric is designed for high permeability and…

More

Other Road/Woven Stabilization Fabrics

Search:

| Product | Roll Width | Roll Length | SF /Roll | SY /Roll | Tensile Strength @ 2% Strain | Tensile Strength @ 5% Strain | Tensile Strength Ultimate | Flow Rate |

|---|

|

Product |

Roll Width |

Roll Length |

SF /Roll |

SY /Roll |

Tensile Strength @ 2% Strain |

Tensile Strength @ 5% Strain |

Tensile Strength Ultimate |

Flow Rate |

|---|---|---|---|---|---|---|---|---|

| -Woven Stabilization Fabric – Standard Grade – 12.5′ x 108′ | 12.5′ | 108′ | 1350 | 150 | NA | NA | 200 lbs/ft | 4 gpm/ft |

| -Woven Stabilization Fabric – Standard Grade – 12.5′ x 27′ | 12.5′ | 27′ | 337.5 | 37.5 | NA | NA | 200 lbs/ft | 4 gpm/ft |

| -Woven Stabilization Fabric – Standard Grade – 12.5′ x 432′ | 12.5′ | 432′ | 5400 | 600 | NA | NA | 200 lbs/ft | 4 gpm/ft |

| -Woven Stabilization Fabric – Standard Grade – 12.5′ x 54′ | 12.5′ | 54′ | 675 | 75 | NA | NA | 200 lbs/ft | 4 gpm/ft |

| -Woven Stabilization Fabric – Standard Grade – 15′ x 360′ | 15′ | 360′ | 5400 | 600 | NA | NA | 200 lbs/ft | 4 gpm/ft |

| -Woven Stabilization Fabric – Standard Grade – 17.5′ x 103′ | 17.5′ | 103′ | 1802.5 | 200 | NA | NA | 200 lbs/ft | 4 gpm/ft |

| -Woven Stabilization Fabric – Standard Grade – 17.5′ x 309′ | 17.5′ | 309′ | 5407.5 | 600 | NA | NA | 200 lbs/ft | 4 gpm/ft |

| -Woven Stabilization Fabric – Standard Grade – 17.5′ x 51.5′ | 17.5′ | 51.5′ | 901.25 | 100 | NA | NA | 200 lbs/ft | 4 gpm/ft |

| .Woven Stabilization Fabric – Intermediate Grade A – 15′ x 300′ | 15′ | 300′ | 4500 | 500 | 1370 lbs/ft | 3600 lbs/ft | 7200 lbs/ft | 15 gpm/ft |

| .Woven Stabilization Fabric – Intermediate Grade B – 15′ x 300′ | 15′ | 300′ | 4500 | 500 | 960 lbs/ft | 2400 lbs/ft | 4800 lbs/ft | 30 gpm/ft |

| .Woven Stabilization Fabric – Intermediate Grade B – 17′ x 265′ | 17′ | 265′ | 4505 | 500 | 960 lbs/ft | 2400 lbs/ft | 4801 lbs/ft | 30 gpm/ft |

| .Woven Stabilization Fabric – Intermediate Grade C – 15′ x 300′ | 15′ | 300′ | 4500 | 500 | NA | 1500 lbs/ft | 3600 lbs/ft | 40 gpm/ft |

| .Woven Stabilization Fabric – Intermediate Grade D – 12.5′ x 375 | 12.5′ | 375′ | 4687 | 520 | 504 | 1272 lbs/ft | 2640 lbs/ft | 40 gpm/ft |

| .Woven Stabilization Fabric – Intermediate Grade D – 15′ x 300′ | 15′ | 300′ | 4500 | 500 | 504 | 1272 lbs/ft | 2640 lbs/ft | 40 gpm/ft |

| .Woven Stabilization Fabric – Intermediate Grade E – 12.5′ x 300′ | 12.5′ | 300′ | 3750 | 400 | NA | NA | 350 lbs/ft | 60 gpm/ft |

| .Woven Stabilization Fabric – Intermediate Grade E – 6′ x 100′ | 6′ | 100′ | 600 | 66.6 | NA | NA | 350 lbs/ft | 60 gpm/ft |

| .Woven Stabilization Fabric – Intermediate Grade E – 6′ x 300′ | 6′ | 300′ | 900 | 100 | NA | NA | 350 lbs/ft | 60 gpm/ft |

| Woven Stabilization Fabric – Heavy Duty Grade A – 15′ x 300′ | 15′ | 300′ | 4500 | 500 | 540 lbs/ft | 1560 lbs/ft | NA | 90 gpm/ft |

| Woven Stabilization Fabric – Heavy Duty Grade A – 17′ x 306′ | 17′ | 306′ | 5202 | 578 | 540 lbs/ft | 1560 lbs/ft | NA | 90 gpm/ft |

| Woven Stabilization Fabric – Heavy Duty Grade B – 15′ x 300′ | 15′ | 300′ | 4500 | 500 | 720 lbs/ft | 2100 lbs/ft | NA | 85 gpm/ft |

| Woven Stabilization Fabric – Heavy Duty Grade B – 17′ x 300′ | 17′ | 300′ | 5100 | 566 | 720 lbs/ft | 2100 lbs/ft | NA | 85 gpm/ft |

| Woven Stabilization Fabric – Heavy Duty Grade C – 15′ x 300′ | 15′ | 300′ | 4500 | 500 | 840 lbs/ft | 1980 lbs/ft | NA | 85 gpm/ft |

| Woven Stabilization Fabric – Heavy Duty Grade C – 17′ x 300′ | 17′ | 300′ | 5100 | 566 | 840 lbs/ft | 1980 lbs/ft | NA | 85 gpm/ft |

Woven Stabilization Fabric Used for Driveway

General Guidance – Driveway Fabric

So, you have decided to construct a gravel driveway in place of the old one you presently have. It will take some work and time but you might be pleasantly surprised when it’s done. Just make sure you follow all necessary steps and make sure you have all the materials you are going to need. You need driveway fabric to create a great driveway with a supportive base layer for a more stable surface that will resist ruts and potholes.

Preparing The Surface For Your Driveway

Before anything else, you have to prepare the surface for your driveway by removing debris such as rocks and stumps which could easily tear the fabric. Next, you have to level the surface without creating a trench that will hold water. If you have an area that holds water, use a pipe or drain to remove the water. Place the fabric directly on the prepared surface by rolling it out so it’s flat and try to keep down any creases or folds. If you need to, overlap the fabric by 1 to 3 inches and then, if needed, use pins or staples to hold it in place. You can also use dirt or other heavy material to hold the fabric in place before dumping the rocks on top. Place the gravel and compact it in 6 to 8-inch lifts. You can use a dump truck or loader driven over the fabric without causing damage but avoid any quick stops or turns. The best approach is to dump the stone on the stabilized fabric and then push it into the fabric for protection. The idea is to create a slight crown in order to provide water drainage on the driveway sides.

What Kind Of Rocks Should Be Used?

The rocks should be crushed and angular with a one-inch diameter and only 10% dust. Limestone is a good choice but if you prefer you can use other stone materials. Some good choices include: Dense Grade Aggregate (DGA) or Crusher Run The advantage of using this fabric, you will not need stones larger than one inch, just make sure you do not use round stones.

Rocks to Use with Woven Fabric

Woven Stabilization Fabric Used for Road

Mistakes You Should Avoid When Creating A Gravel Driveway

If you do not have a problem with the extra maintenance needed for a gravel driveway, the cost will be a great deal less than a paved driveway and will last just as long. If constructing this gravel driveway is the first time for you, there are mistakes you must avoid: Stay Away From Soft Spongy Ground Do not spread gravel on ground that is soft. If the soil is loaded with leaves, grass, roots, weeds, or other debris you will have a spongy surface that will lead to problems down the road. Get rid of topsoil and strip the soil down to the hard rock. It will help create a more stable and dependable bed. You can always use the topsoil somewhere else.

Poor Drainage

If your driveway is not correctly leveled, drainage will become an issue. An unleveled driveway will allow water to erode and damage the driveway. You will end up with a mud hole with silt from below coming up to the gravel. The silt will loosen the gravel and lose the needed friction which will cause weakening and separation.

Prevent Gravel From Moving

To prevent the gravel from moving, a gravel paver product can be optionally used to prevent gravel from moving. It will prevent rutting and offer a very stable surface. Gravel Pavers come in many different shapes and sizes and are made from either plastic or a heavy-duty geotextile. Another good option is installing sides to the driveway. The sides can be made of wood or you can create a retaining wall with brick or concrete blocks. These materials will prevent spreading outside the parameters of the driveway.

Avoid The Wrong Size And Shape Of Gravel

The base layer of gravel fragments should be at least 3 to 4 inches in diameter or you will experience shifting and sinking when you drive over it. The gravel fragments must be angular with sharp edges. Rounded rock fragments are not a good choice because they cannot lock into place with other pieces. Sharp-edged fragments are just as solid as a single large rock. The gravel laid on the final top layer should not be any larger than a golf ball. The total thickness of the driveway, with layers of different sizes of gravel, should be around 12-inches.

Each Layer Must Be Properly Compacted

Even though the driveway should be constructed of various layers of gravel, each layer must be compacted properly. If not, the driveway will not keep its shape. Each layer should be around 4-inches thick and the gravel fragments should be smaller than the layer below it. Each layer must be properly compacted by tamping down each layer using a hand-operated machine or roller.