PP Needle Punched Nonwoven Geotextile

PP Non woven geotextile has good physical and hydraulic properties, especially in tensile strength, aspect strength ratio, uniformity and other advantages.

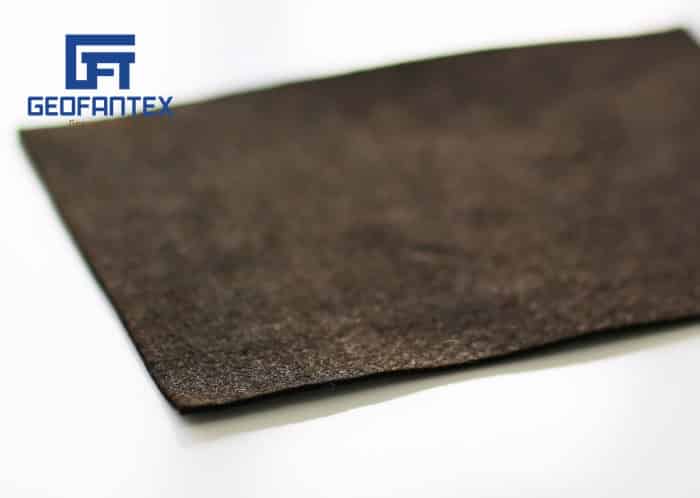

- Material:Polypropylene Fibre

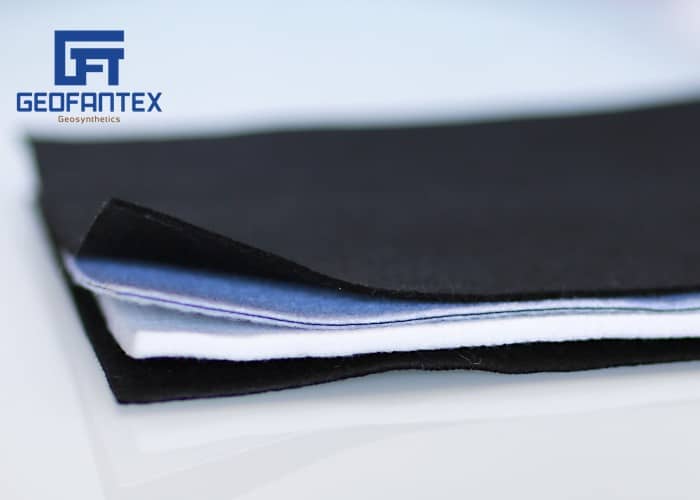

- Color: White or Black

- Length: 50m-100m

- Width: 1-6m

- Certificate: CE /ISO9001/SGS

- Type: Needle Punched

- Supply Ability:60000 Square Meters per Day

- Customization:

- Customized logo (Min. Order: 5000 Square Meters)

Customized packaging (Min. Order: 5000 Square Meters)

Graphic customization (Min. Order: 5000 Square Meters)

- Lead Time: With in 7days per container

| Quantity(Square Meters) | 1 – 10000 | >10000 |

| Est. Time(days) | / | Negotiable |

Categories: Nonwoven Geotextiles, PP Nonwoven

Description

PP Needle Punched Nonwoven Geotextile

- Nonwoven geotextiles are multi-purpose fabrics that are felt-like in appearance. PP needle punched geotextile is manufactured from short synthetic fabric (polypropylene fiber).The product is formed after the processes of opening,combing,mixing and disordering,lapping and needling.

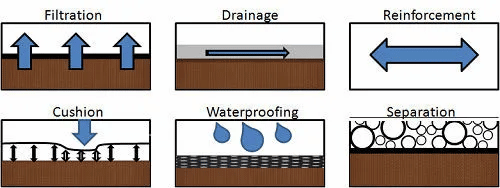

- PP Nonwoven Geotextiles has good impermeability and resistance to deformation, which allows geotextiles be widely applied in civil projects for separation,filtration,reinforcement, protection and drainage.

Product Features

- Excellent drainage performance

- High strength,excellent tenacity

- Anti-aging,anti-acid and alkali

- Can accommodate irregular deformations

- Creep, corrosion and abrasion resistance

- Safe and easy for construction

Application

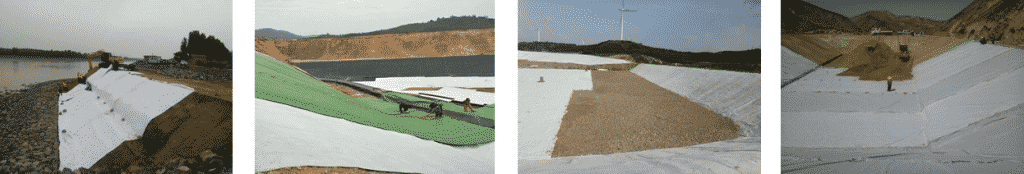

Nonwoven geotextiles have a wide range of applications in civil environmental engineering and construction projects.

- Filtration

When water passes from a fine-grained to a coarse grained layer, Non-woven Geotextiles can retain fine particles well. Such as when water flows from a sandy soil into a Geotextile wrapped gravel drain.

- Separation

To separate two layers of soil with different physical properties, such as the separation of road gravel from soft sub-base materials.

- Drainage

To drain liquid or gas from the plane of the fabric, which leads to draining or venting of the soil, such as the gas vent layer in a landfill cap.

- Reinforcement

To improve the load bearing capacity of a specific soil structure, such as the reinforcement of a retaining wall.

Specifications

PP Needle Punched Non-woven Geotextile

Polypropylene (PP) Nonwoven Geotextiles have main functional mechanical properties, permeable or impermeable properties, and soil-tightness. The data sheet as the blow is part of mechanical properties, not full of it. The permeable properties, loading quantities, or other details will be mailed to you if needed. As bellows.

(* Geofantex Geosynthetics can produce GeofanTex® GFP according to your requirement in constructions, MINIMUM ORDER QUANTITY: 20’ft Container)

| Properties (Standard) | Unit | GFP 100 | GFP 150 | GFP 200 | GFP 250 | GFP 300 | GFP 350 | GFP 400 | GFP 450 | GFP 500 | GFP 550 | GFP 600 | |

| Tensile Strength [ASTM D 4595] | T M | KN/m | 6.0 4.8 | 10 7.8 | 13 11 | 17 15 | 21 17 | 25 19 | 29 23 | 32 25 | 34 26 | 38 28 | 44 31 |

| Tensile Elongation [ASTM D 4595] | T M | % | 80 50 | 70 50 | 70 50 | 70 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 |

| Grab Strength [ASTM D 4632] | T M | KN | 0.37 0.29 | 0.52 0.39 | 0.65 0.52 | 0.87 0.70 | 0.99 0.75 | 1.32 1.09 | 1.58 1.33 | 1.75 1.35 | 1.94 1.54 | 2.07 1.64 | 2.3 2.1 |

| Grab Elongation [ASTM D 4632] | T M | % | 80 50 | 70 50 | 70 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 |

| Properties (Standard) | Unit | GFP 800 | GFP 1000 | GFP 1200 | GFP 2000 | |

| Tensile Strength [ASTM D 4595] | T M | KN/m | 56 42 | 67 51 | 82 65 | 135 102 |

| Tensile Elongation [ASTM D 4595] | T M | % | 60 50 | 60 50 | 60 50 | 60 50 |

| Grab Strength [ASTM D 4632] | T M | KN | 2.9 2.1 | 3.4 2.4 | 4.55 3.23 | 7.15 5.43 |

| Grab Elongation [ASTM D 4632] | T M | % | 60 50 | 60 50 | 60 50 | 60 50 |

The light PP Staple Fiber Nonwoven Geotextile (GeofanTex® GFP) has a filter and separation function, the main properties of heavy PP Staple Fiber Nonwoven Geotextile (GeofanTex® GFP) for reinforcement are Strength, stiffness, and the conservation of these properties during the life cycle of construction.

1. Geotextile for Filtration and Separation

PP Staple Fiber Nonwoven Geotextile (GeofanTex® GFP) provides superior hydraulics and soil retention, making them ideal for filtration in subsurface drainage systems. PP Staple Fiber Nonwoven Geotextile (GeofanTex® GFP) extends the performance life of the road, and also reduces the overall thickness of the road structure by requiring less aggregate during construction.

2. Geotextile for Reinforcement

PP Staple Fiber Nonwoven Geotextile(GeofanTex® GFP) is commonly installed in the construction of embankments, which let the water pass out and retain the particles, decreasing the slope damage.

Applications of Non Woven Geotextile

- •Roads (including temporary roads), railways, embankments, earth-rock dams, airports, sports fields, etc., are used to strengthen weak foundations and at the same time to isolate and filter. The geotextiles on the banks of rivers, rivers, lakes, and seas can also prevent the water from turbid.

- •Reinforcement non woven geotextile in backfilling of retaining walls, or panels used to anchor retaining walls. Construct a wrapped retaining wall or abutment.

- •Reinforce the flexible pavement nonwoven geotextile, repair the cracks on the road, and prevent the pavement from reflecting cracks.

- •Nonwoven geotextile Increase the stability of gravel slopes and reinforced soil to prevent soil erosion and freezing damage to the soil during low temperatures.

- •The separation layer nonwoven geotextile between the roadway and the roadbed, or the separation layer between the roadbed and the soft foundation.

- •Separation nonwoven geotextile between artificial fill, rock fill or material field and foundation, and separation between different frozen soil layers. It acts as a filter and reinforcement.

- •The filtration layer nonwoven geotextile of the initial upstream dam surface of the ash storage dam or tailing dam, and the filter layer of the drainage system in the backfill of the retaining wall.

- •The filtration nonwoven geotextile layer around the drainpipe or the gravel drain ditch.

- •Nonwoven geotextile filtration layers for water wells, relief wells or barbed pipes in water conservancy projects. •Separation of geotextiles between the road, airport, railway ballasts and artificial rock fills and foundations.

- •Vertical or horizontal drainage nonwoven geotextile inside the earth dam, buried in the soil to dissipate the water pressure in the gap.

- •Drainage nonwoven geotextile behind the anti-seepage geomembrane in the earth dam or earth embankment or in the lower part of the concrete facing.

- •Nonwoven geotextile excludes water seepage around the tunnel, reduces the external water pressure on the lining and seepage water around each building.

- •Drainage of the base nonwoven geotextile of the ground-based sports ground.

Geofantex Geosynthetics have to make a series of guarantee for our products both plant processing and selling out to our customers. Selling to you is the first step, the service, and guarantee are our tasks. Geofantex Geosynthetics have an ISO Certificate to guarantee the raw material, the product processing, and the end product. From receiving your order to replacement and installation of the products, we have solved the problems in time if you need, whatever the quality and technics guidelines or suggestions. Our company has been committed to supplying high-quality products with reasonable prices and delivery on time.

MANUFACTURING QUALITY ASSURANCE

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at the factory. GEOFANTEX maintains a high level of quality and up-to-the-minute results on finished products through a fully equipped, well-staffed, dedicated laboratory existing in each of the manufacturing facilities. Each facility follows the same guidelines for evaluating the quality of GEOFANTEX products and is capable of adapting to market-driven requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define the implementation of basic manufacturing quality assurance (MQA) procedures necessary to ensure the consistent production of quality products supplied to the geosynthetic market. Note that at this time, these procedures are limited to polypropylene staple fiber nonwoven geotextile.

B. Scope

In order to achieve GEOFANTEX’s stated purpose, a rigorous set of minimum standards and an effective test program to assure compliance have been established. These procedures and requirements are frequently reviewed and adjusted to assure compliance with current market demands and/or predetermined project specifications. These procedures assure that raw materials and process parameters are controlled to provide products complying with GEOFANTEX’s pre-defined minimum characteristics.

PRODUCT IDENTIFICATION AND DOCUMENTATION

A. Roll Numbering

Each roll of geotextile is assigned a unique roll number. The Quality Assurance Laboratory maintains records documenting the raw materials and resulting product quality information.

B. Approval Procedure

Results for each tested roll of the product are checked against both GEOFANTEX China standards and customer specifications for compliance. The Quality Assurance Laboratory approves those materials that meet these requirements for shipment.

C. Non-Conformance

Material that does not meet GEOFANTEX minimum standards is given a roll number but is rejected and not placed into inventory. The material is identified as scrap and will not be utilized. Material that meets GEOFANTEX minimum standards but does not meet a stricter customer specification is not allocated to that customer but is placed into inventory as GEOFANTEX standard material.

D. Documentation

Individual Quality Assurance Certificates are generated and supplied for each roll of needle punched nonwoven geotextile product to include all relevant quality assurance information about the material(s).

Geofantex Geosynthetics have a series of package and delivery service working procedures. Geofantex Geosynthetics have supplied thousands of containers to Latin America, North America, Southeast Asia, developed countries, and Africa within the past ten years. We provide the package of products with the rolls, pots, bags, sheets, or your requirement in orders. Our company has been committed to supplying high-quality products with reasonable prices and delivery on time. Delivery one 40’HQ within 7 – 10 days. And we have an obligation in increasing loading quantity and make you save the freight costs maximumly. We supply the products by plane, by sea, and by land carriage to any region or any countries of the worldwide, even the door-to-door service.

What is needle punched geotextile?

Νeedle punched, Nonwoven geotextiles produced from polypropylene staple fibers. Nonwoven geotextiles are used in many civil engineering and building applications and are designed to offer filtration, separation, and erosion control functions. They are exceptional for road, railway, drainage, and landfill applications.

What are the two main types of geotextiles?

Geotextile fabrics come in three basic forms: non- woven geotextiles, woven geotextiles (needle punched), or heat bonded geotextiles (structural woven).

What is the needle punching process?

Needle punching is one of the methods used for making a nonwoven felt. This involves taking loose fibers and “needling” them together using a needle loom full of barbed needles to force the fiber to push through and entangle itself.

Package Details

- PE film or PP woven bag for outpackage or as your reqeust.

Additional information

| Color |

White/Black |

|---|---|

| Roll Width |

1-6m |

| Roll Lengt |

50m-100m |

| Material |

Polypropylene |