Uniaxial Geogrid

Singhal Industries is a number one Manufacturer of Uniaxial Geogrid globally, making on a large scale with outstanding quality. Many customers use our products to stabilize soils and improve their moisture and nutrient retention.

Uniaxial Geogrid is a type of soil that has been specifically designed to withstand high winds and heavy loads. It is a good option for sites exposed to high levels of wind or weather conditions, such as wind turbines, construction sites, and agricultural fields. Monoaxial Geogrid can also be used in areas where water runoff is an issue. It contains unique properties that help reduce the intensity and amount of water flowing off the site. Singhal Industries Private Limited is one of the best manufacturer of monoaxial Geogrid in the country and provide Geogrid related products worldwide.

Geonet – Geo Fabric

Uniaxial Geogrid

Description Features Advantages Applications Specification Reviews Questions

What is Uniaxial Geogrid?

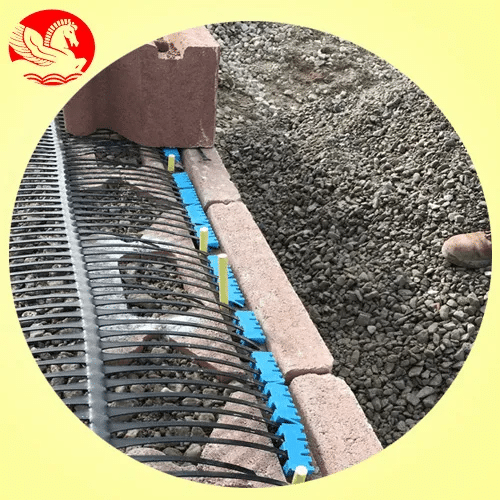

The Uniaxial Geogrid is a particular type of cloth and netting-based geosynthetic material used to reinforce soil beneath pavements and highways. This article defines the monoaxial Geogrid, provides insights into its advantages and disadvantages and provides information on the materials that make up the material.

What are High-Density Polyethylene Uniaxial Grids?

High-density polyethylene (HDPE) uniaxial geogrid is a type of geogrid that has been used in construction since the 1940s. They are designed to be used on both highways and in industrial settings, but they have become more popular with the construction industry in recent years.

HDPE uniaxial geogrid is made from high-density polyethylene (HDPE) plastic. The density of this material makes it strong enough to withstand heavy weight loads without deforming or cracking. It also has good tensile strength, which means it can hold its shape under stress.

In addition to being strong and flexible, HDPE uniaxial geogrid also have good abrasion resistance, so they can withstand rough surfaces without tearing or ripping apart. They’re also resistant to chemicals like gasoline or oil, making them safe for use around fuel tanks and other areas where chemicals may be present during installation or use.

Importance of Uniaxial Geogrid?

Monoaxial geogrid is an essential material for construction and civil engineering applications. It has several advantages over other materials, such as being lightweight and having good stability. The uniaxial nature of the geogrid makes it an excellent choice for constructing roads, bridges, and other large infrastructure projects. The geogrid can also stabilize unstable soil and protect it against erosion.

How does Monoaxial Geogrid work?

Uniaxial geogrids are a type of soil reinforcement typically used in construction and agricultural applications. They are made from sand, silt, and clay and are usually measured in pounds per square foot. They can be used to stabilize soils and improve their moisture and nutrient retention. The most commonly used monoaxial geogrid is a concrete reinforcement mesh (CM), which comprises aggregate or a concrete mesh. These meshes are used to reinforce the soil and improve its compressive strength. The amount of CM per square foot varies depending on factors such as grade, moisture, and natural materials that can be found in the soil. Geogrids are used as soil stabilizers to stabilize the soil and reduce settling or cracking.

What are the different uses for Uniaxial Geogrids?

Uniaxial Geogrids can be used in a variety of ways. Some examples are foundations for buildings, drainage systems, and even roads. You would use Monoaxial Geogrids to dig it up and then pave the soil over it. This would be done to make a foundation for buildings or even a road. These are often used in constructing roads because they can carry heavy loads much better than other materials like bricks or concrete. The large size of Uniaxial Geogrids allows them to last longer and stand up to more stress. Therefore, they are very well suited for traveling roads, especially if they have been built on stony ground.

These are much more stable than Strain Geogrids. They can withstand tension and compression with equal ease and take on thousands of pounds of weight without cracking. Making geogrid involves laying the surface layer very flat to be perfectly smooth. Compressive stress can also affect the integrity of a Strain Geogrid, but it is far less likely to cause cracks in them than tensile stress.

Another reason that Uniaxial Geogrids hold up so well is that they do not tend to damage easily as a Strain Geogrid would. For example, if you were to carry a piece of Strain Geogrid, the weight would cause it to begin to crack and deform. The uniaxial stress of any geogrid form is less likely because it does not tend to degrade as quickly or as easily. When a monoaxial Geogrid is appropriately installed and placed in top condition, it will support the weight of whatever you are installing it on whether you want it to or not! It is essential that when purchasing geogrids that they be installed appropriately.

Singhal Industries Private Limited is a manufacturer and trusted exporter of such products to the USA, UK, UAE, Australia, and the entire world.

What are the Features of Uniaxial Geogrids?

Uniaxial geogrids are a type of soil that has a uniaxial orientation. This means that the grains in the soil are oriented in one direction only. Uniaxial geogrids have many benefits for soil erosion control, including:

- They provide a stable foundation for plant growth and prevent erosion by water and wind

- They resist compaction and improve aeration and drainage

- They reduce the amount of water required to retain moisture in the soil

- They improve the physical and chemical condition of the soil by holding more air, water, and nutrients.

- Good Creep Resistance

- Quick Installation

- High Tensile Strength

The orientation of each grain in uniaxial geogrids is determined to be parallel to the direction of least resistance.

Advantages of Uniaxial Geogrids

When constructing soil or foundation materials, there are many advantages to using uniaxial geogrids. Geogrids provide stability and uniformity across a large area, which can be beneficial when constructing foundations or constructing soil in regions prone to shifting or settling. Additionally, geogrids can help to conserve water and reduce erosion. Because geogrids provide a consistent spacing across the surface, they can be used to create a structure such as a barrier. An embankment is an artificial barrier that slows or stops the movement of water in certain areas. This type of barrier can help control erosion, and it can also provide a stable foundation for any structures built on top of it.

Geogrids are also used to prevent soil erosion. When a geogrid is laid out on top of the soil, the soil becomes pressed into the grid wire, and the soil’s natural ability to absorb water is effectively limited. This prevents runoff and erosion from taking place, which can help to conserve the water supply and preserve the environment.

Applications of Uniaxial Geogrid

Uniaxial geogrid is a type of soil surface with a consistent, uniform texture and can be used in various applications.

- Uniaxial Geogrid is most commonly used as a surface for construction and agricultural purposes, but it can also be used in automotive manufacturing and paintball fields.

It is important to note that Uniaxial Geogrid is not a substitute for traditional soils, and it cannot hold water or nutrients and should not be used in areas that require these properties. Additionally, uniaxial geogrid is not resistant to erosion or decay.

- It is Environment Friendly, and it PRevents Soil from Erosion.

- The use of Uniaxial Geogrid results in more economical construction.

What are the specifications of Uniaxial Geogrids?

Uniaxial Geogrids are a type of geotextile fabric used as a soil reinforcement or drainage control material. They are made of a single layer of strong, smooth textile fibers tightly woven together to form a grid. Uniaxial geogrids have certain vital specifications that make them the perfect choice for many applications. Below are some of its specifications.

- They are solid and resistant to tearing.

- They have excellent drainage properties, effectively controlling water retention and preventing flooding.

Uniaxial geogrids are easily installed and can be cut to any desired shape or size.

Rate Our Service

Your review

Your overall rating Select a Rating 5 Stars 4 Stars 3 Stars 2 Stars 1 Star

Your name

Your email

Your review

Submit your review

Reviews from Our Customers

There are no reviews yet. Be the first one to write one.

Ask a Question

Your email address will not be published. Required fields are marked *

Comment *

Name*

Email*

Website

No queries found. Be the first one to ask a question.

Customer also bought

-

-

Geocell Material its Structure and use in Road Construction

-

‹›