Home Depot Retaining Wall Reinforcement Grid

What is the best geogrid for a retaining wall?

Large roll geogrids are most resilient in the direction of the roll or machine orientation and are typically cut to specific design lengths. These geogrids are particularly well-suited for constructing retaining walls that exceed a height of 6 feet (1.8 meters).

How far back should geogrid go on a retaining wall?

When constructing a retaining wall, it is important to consider the placement of geogrid. In most cases, the geogrid should be installed at the designated elevation for the entire length of the wall, until a step is reached. Minimum reinforcement lengths of at least 5 feet (1.5 meters) and a 70% reinforcement length to wall height ratio should also be observed. For best results, it is recommended to use the same vertical spacing for geogrid throughout the entire wall. By taking these factors into consideration, you can ensure that your retaining wall is properly reinforced and built to last.

Reinforcement Grid for Retaining Wall

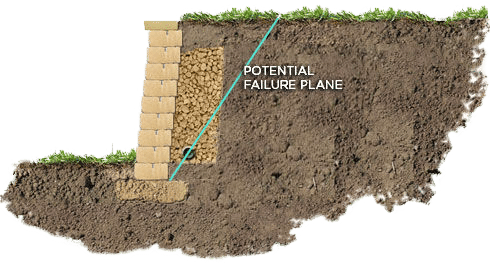

Retaining Wall with Unreinforced Soil, Cross Section.

Retaining walls are designed to prevent the collapse of soil masses that may be prone to instability. The maximum height of an unreinforced VERSA-LOK wall can range from three to four feet, depending on factors such as the type of VERSA-LOK unit used, soil type, and site conditions. However, it is important to note that the stability of the wall may be affected by poor soil quality, additional loads, or slopes on the top or bottom of the wall. Therefore, it is crucial to consider these factors when designing and constructing a retaining wall to ensure its stability and effectiveness.

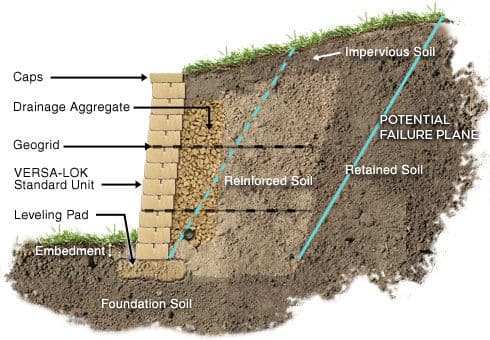

Retaining Wall with Reinforced Soil, Cross Section.

Geogrid soil reinforcement is necessary when the weight of VERSA-LOK wall units alone cannot withstand unstable soil or a heavy load. Horizontal layers of geogrid provide tensile strength, making the reinforced soil mass an integral part of the retaining wall system. As the wall grows taller, longer and stronger geogrids are needed to ensure the reinforced soil mass is properly connected to the VERSA-LOK units, increasing the wall’s size and weight to resist pressure from behind.

Retaining Wall Reinforcement Grid Strength Calculation

Geogrids come in different types with varying tensile strength and widths of 3.65 m, while their length is dependent on design requirements. Ultimate strength is determined through tests following either ASTM or GRI standards, with long term design strength calculated using a safety factor that considers degradation, construction damage, and material deficiency. For Long Term Allowable Design Strength, a design safety factor of 1.5 is used, with geogrids commonly anchored into the facing wall joints and in-situ soil for effective utilization. Resistance against pullout is achieved through friction coefficient and engagement techniques like pins or folding over a lip in the block.

The connection values between blocks and different geogrid types are determined through testing. The ultimate connection value for blocks is computed using Equation-1: Peak connection strength = 425 + 0.27N, with a maximum of 8.45 KN. In this equation, 425 represents the proprietary geogrid engagement value to the block, 0.27 is the tangent of the block-geogrid-block friction angle, and N is the weight of the overlaying blocks. A safety factor of 1.5 is used for connections to ensure safety and reliability.

Design Criteria for Geogrid Segmental Retaining Wall

Retaining walls play a crucial role in civil engineering projects, providing structural support to keep soil and rock in place. When planning for a retaining wall, several factors must be considered, including the height along its length, plan view alignment, and contouring. In some cases, sloped backfill may be necessary, making it crucial to determine the characteristics of both in-situ and backfill soil.

Consultants play an essential role in providing values for internal friction and density, as well as necessary recommendations for global stability. It’s important to ensure that the backfill materials used are well-drained and meet the requirements of the Unified Soil Classification System, with the GW group being ideal for backfill material.

To achieve a stable and reliable retaining wall, it’s crucial to assess the soil properties, including internal friction and density. Additionally, global stability checks may be necessary to ensure the overall stability of the project. With careful planning and expert consultation, a retaining wall can provide reliable structural support, even in challenging terrain.