Geogrid: The Answer to Prevent Structural Failure

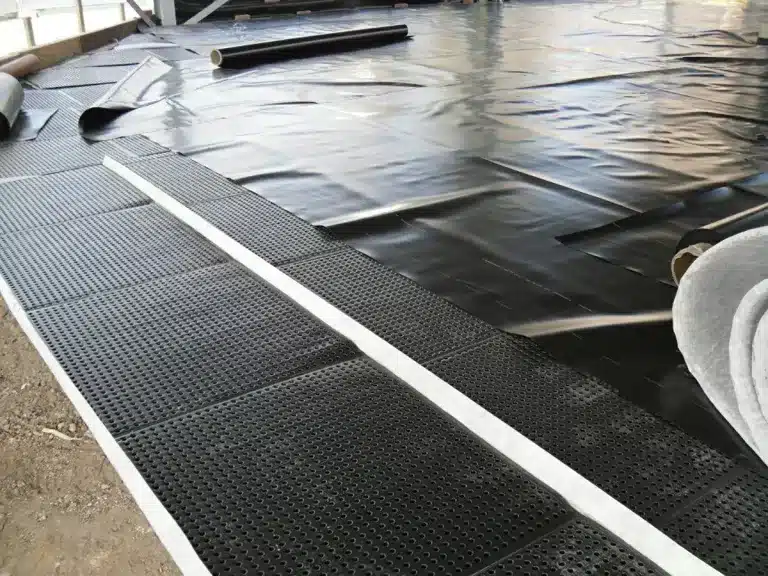

Established construction companies are increasingly relying on geogrids to prevent structural failure, as these materials are highly effective in reinforcing substrates. One of the best ways to gauge the dependability of triaxial geogrids is through their junction integrity, defined by a term known as ultimate junction strength.