Nonwoven geotextile fabrics are often referred to as ‘multipurpose’, and to a great degree deliver on that promise. Contributing to their popularity is their cost-of-manufacture to weight ratio is less than their woven counterparts. The manufacturing process of nonwoven geotextiles is very different from that of woven geotextiles, with needlepunched finishing as the leader. When used in filtration applications it is important to note that the actual mechanics of this function by nonwoven geotextiles are much different than the original woven monofilaments.

For a complete history of Carthage Mills and the geosynthetics industry, see Geosynthetics: How it all began…, or a featured article by Geosynthetica on geosynthetica.com.

View All Products

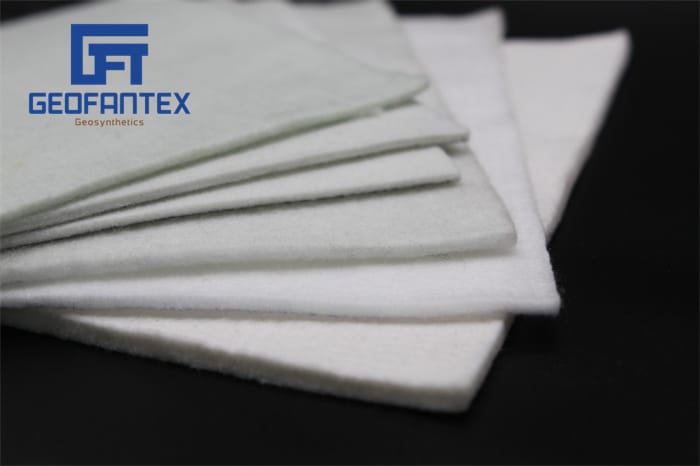

Nonwoven geotextiles consist of fibers that are either continuous filament yarns or short staple fibers which are then bonded together by various processes that can include a needling process that intertwines the fibers physically (needlepunched), or a chemical / thermal bonding operation that fuses adjacent fibers together. The resulting nonwoven geotextiles have a random fiber orientation with high porosity and permeability, indirect and unpredictable openings, a thickness ranging from thick felt to a relatively thin fabric, and low modulus with high elongation.

Carthage Mills Series of Nonwoven Geotextiles

GEOFANTEX-GFS Series (Civil)

Carthage GEOFANTEX-GFS Series of nonwoven geotextiles are often times considered ‘multipurpose’ geotextiles as they can offer immediate and cost effective solutions for many separation, drainage, erosion control and filtration applications. Read more…

- Subsurface Drainage Systems; Under Riprap/Hard Armor in Erosion Control; Separation under Streets, Railways, Roadways and Pavers; Swales; Filtration/Drainage in SRW and Landfill Applications; Under Athletic Fields

GEOFANTEX-GFP Series (Environmental)

Carthage GEOFANTEX-GFP Series of nonwoven geotextiles are specially designed for a wide variety of applications in the environmental market. They offer immediate and cost–effective solutions for many of the unique challenges found in these types of applications. Read more…

- Landfill/Waste Collection Drainage and Filtration Systems; Geomembrane Protection; Gas Collection and Venting Systems; Liquid and/or Gas Pressure Relief Systems

GEOFANTEX-GFE Series of Asphalt Overlay Fabrics

Carthage GEOFANTEX-GFE nonwoven polypropylene Asphalt Overlay geotextiles for Pavement Restoration, Sealing, Stress Relief and Asphalt Adhesive Bonding. Read more…

- Parking Lots; Highways; Streets; Airports; Bridges; Basketball Courts; Tennis Courts

American Association of State Highway and Transportation Officials and AASHTO: M288-15

A joint committee, formed from the American Association of State Highway and Transportation Officials (AASHTO) and the Industrial Fabrics Association (IFAI), developed a general platform to standardize geotextiles for general transportation applications. The current revision for this standard is AASHTO: M288-15.

AASHTO: M288-15 is NOT a design guideline. The selection criteria are based on an engineer’s knowledge of the site-specific installation stresses and soil hydraulic properties for the project application. Click here for a Geotextile Selection Guide and the appropriate Carthage Mills product. For further information on Carthage Mills and AASHTO: M288-15 contact your local Carthage Mills Representative or call (800) 543-4430. To order a copy of the complete AASHTO: M288-15 Specification, contact AASHTO at (202) 624-5800.

Click Here to view Geotextile Products Overview

Call or E-mail us for Product Information, Pricing and Availability.