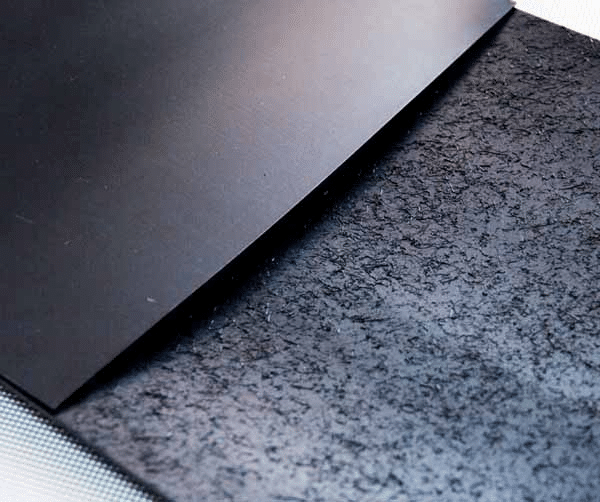

Geomembrane is usually divided into HDPE smooth surface geomembrane and HDPE textured surface geomembrane according to the surface. Their main components are composed of 97.5% high-density polyethylene and 2.5% carbon black. The main function of carbon black is anti-aging and anti-oxidation. and UV resistance. The difference between HDPE smooth surface geomembrane and ane is usually divided into HDPE smooth surface geomembrane and masks is that they have densely textured spots on their surfaces, only one side with textured spots is called single textured geomembrane, those with textured spots on both sides are called double textured geomembrane, and those without textured spots are smooth geomembrane.

HDPE geomembrane liner has excellent temperature adaptability, weldability, weather resistance, good aging resistance, chemical resistance, environmental stress crack resistance, and puncture resistance. Therefore, it is especially suitable for underground engineering, mining engineering, landfill, sewage, or waste treatment site as anti-leakage material.

Textured surface HDPE geomembrane liner has excellent temperature adaptability, weldability, weather resistance, good aging resistance, chemical resistance, environmental stress crack resistance, and puncture resistance. Textured surface HDPE geomembrane liner is a new type of anti-seepage material. HDPE geomembranes liner such as single textured surface and double textured surface increase the friction coefficient and anti-skid function, which are more suitable for steep slope and vertical anti-seepage, and improve engineering stability.

Textured HDPE Geomembrane Textured HDPE Geomembrane

Types of textured surface geomembrane

Single Textured Surface Geomembrane

Single textured surface geomembrane: single textured surface geomembrane is a geomembrane with one textured side and one smooth side. In the construction of slope anti-seepage engineering, the textured side of the single textured surface geomembrane is often in contact with the geotextile so as to play a non-slip effect.

Double Matte Finish Geomembrane

Double-textured geomembrane: Double-textured geomembrane is a geomembrane with textured surfaces on both sides. Double-textured geomembrane is widely used. A double-textured geomembrane can be in contact with geotextiles on both sides in the construction of slope anti-seepage projects. Anti-slip effect.

Column Point Anti-Skid Geomembrane

Pillar point geomembrane: A pillar point geomembrane is a geomembrane with uniform raised points on one or both sides. The textured points of the pillar point geomembrane are evenly distributed and beautiful. Column-point geomembrane can also be used in slope anti-seepage projects to achieve anti-seepage, anti-skid, and anti-fouling effects.

Tailings Pond Project

Landfill Liners Project

Performance comparison of traditional technology textured surface and anti-skid column point textured surface geomembrane

| Product Name/Technical Specifications | Tensile strength MPa | Elongation% | friction coefficient |

| Performance comparison of traditional technology textured surface | ≥11 | ≥100 | 0.4 |

| anti-skid column point textured surface geomembrane | ≥28 | ≥300 | 0.8 |

The textured geomembrane is mainly used in the slope anti-skid and seepage prevention and closure of some daily garbage landfills, tailings ponds, and other projects; while the smooth geomembrane is used in the bottom of the landfill, artificial lakes, reservoirs, and other projects in the impermeable body. textured geomembrane has a better elongation at break and resistance to environmental stress cracking and better environmental adaptability than glossy geomembrane.

Generally speaking, both single-textured geomembrane and double-textured geomembrane can improve the anti-seepage, anti-aging, and anti-ultraviolet capabilities of the geomembrane, and can also increase the friction coefficient between the geomembrane and the construction surface, which can better solve the anti-seepage of the slope. need.

Due to the continuous leakage of heavy metals in mines and the diffusion of toxic gases in mine waste residues, the pollution level has been accelerated. Therefore, people are paying more and more attention to environmental protection issues, and the country’s requirements for environmental protection are getting higher and higher.

The problem that the mining industry must face is anti-seepage and anti-leakage. At present, the more common method is to cover and seal with anti-seepage geomembrane materials. Generally, textured surface geomembrane is used more. Textured surface geomembrane has strong anti-slip properties on hillsides, and can effectively prevent impact in severe weather conditions such as strong winds and rainstorms.

Smooth Geomembrane VS Textured Geomembrane

The thickness specification of HDPE textured geomembrane is generally 0.5 mm to 2 mm, and the thickness is less than 0.5 mm, which will affect the anti-seepage, ductility, and anti-aging functions of the geomembrane. , will increase the difficulty and time of construction. It is generally recommended to use a geomembrane with a thickness of 1.0 for the tailings pond project. During construction and welding, care should be taken not to allow machines and workers to step on it excessively. Before laying the membrane, the broken surface should be cleaned to prevent sharp objects from piercing the geomembrane. material, which affects the later anti-seepage. The textured surface geomembrane will not have the possibility of the protective layer slipping due to the textured surface. In order to increase the friction coefficient, it is beneficial to the steep slope and vertical seepage prevention and improves the engineering stability. Therefore, the textured surface geomembrane is widely used. Textured surface HDPE geomembrane liner has excellent temperature adaptability, weldability, weather resistance, good aging resistance, chemical resistance, environmental stress crack resistance, and puncture resistance. It is mainly used for anti-seepage on steep slopes. The reason why the textured-surface anti-seepage geomembrane is used is to enhance the friction between the geomembrane and the slope surface to prevent slippage and improve engineering stability.

Because of the large friction coefficient and good anti-seepage performance of textured geomembrane, textured geomembranes, composite geotextiles, and non-woven fabrics are widely used in landfills, tailings pond bottoms, conditioning treatment pools, dam water conservancy, evaporation ponds, waste landfills, biogas digesters, and other anti-seepage projects.

If you happen to have tailings or landfill projects under construction or planning, contact me and I will send you a proven solution. If you need samples of textured HDPE sheets or HDPE smooth geomembrane, our company is happy to provide you with free samples.

Request Free Quote

Rate this post