Maximizing Stability with Geogrid for Soil Stabilization

Geogrid for Soil Stabilization with original, spot supply, and direct manufacturer support. Contact us for bulk orders.

Tel: +86-411-39569550 | E-mail: info@geofantex.com/geofantex@gmail.com

Geogrid for Soil Stabilization with original, spot supply, and direct manufacturer support. Contact us for bulk orders.

Geogrid for road construction stands as a game-changer in the realm of infrastructure. These innovative materials, meticulously designed and strategically placed within road layers, bolster structural integrity and longevity.

Geogrid reinforcement is a critical aspect of civil engineering and construction. In this article, we’ll delve into what geogrid reinforcement is, its uses, and its significance. We’ll also address some key questions to provide a comprehensive understanding of this vital construction technique.

When considering geotextile driveway fabric cost, various factors come into play that significantly influence pricing.

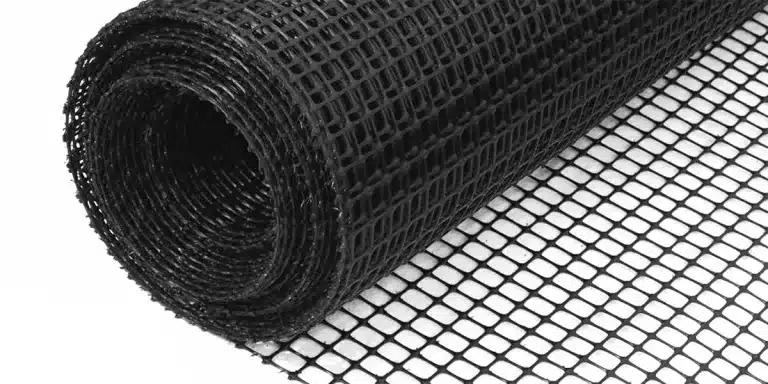

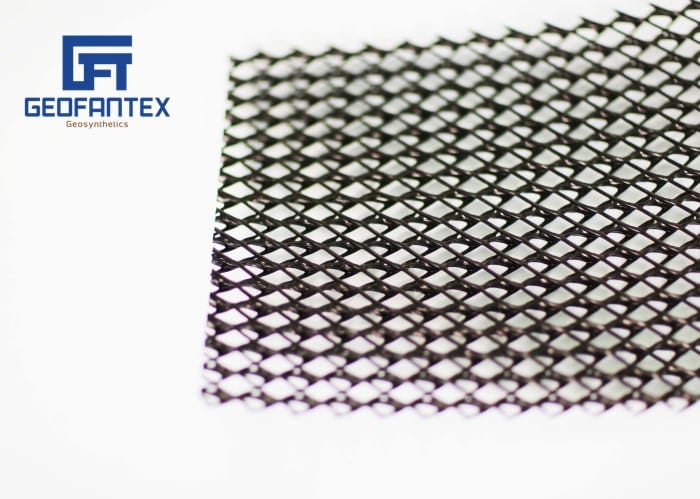

Geogrids are essential in modern construction and civil engineering. In this article, we’ll delve into geogrids – a geosynthetic material used to reinforce soils and similar materials. We’ll explore their applications, when and why they’re used, the various types available, and the benefits they bring over traditional construction methods.

Understanding the diverse geosynthetic functions is pivotal in modern engineering and construction landscapes. Geosynthetics play an indispensable role in infrastructure development, boasting a spectrum of functions such as separation, filtration, drainage, protection, reinforcement, erosion control, barrier creation, and stress relief.

Geotextile fabrics are indispensable in various civil engineering and landscaping projects. However, selecting the right geotextile fabric is crucial for project success. In this article, we will explore the recommended geotextile fabrics, and types, and offer insights on how to make the right choice for your specific needs.

Geomembrane solutions are a crucial innovation in various industries, from environmental protection to agriculture and construction. This article delves into the key aspects of geomembranes, including their materials, applications, and different types. It aims to provide a comprehensive understanding of geomembrane solutions.

Geogrid backfill reinforcement stands as a cornerstone in fortifying structures across diverse construction projects.

Geosynthetics play a crucial role in civil engineering and environmental projects, and two common types are geonets and geogrids.

End of content

End of content

WhatsApp us