Tel: +86-411-39569550 | E-mail: info@geofantex.com/geofantex@gmail.com

Tel: +86-411-39569550 | E-mail: info@geofantex.com/geofantex@gmail.com

Geogrid backfill reinforcement stands as a cornerstone in fortifying structures across diverse construction projects. By integrating geogrids within backfill materials, construction endeavors experience a transformative enhancement in structural stability and durability. This innovative reinforcement technique effectively redistributes loads, curtails settlement risks, and mitigates the impact of lateral pressures. Whether in the realm of retaining walls, bridge abutments, or other vital infrastructure, geogrid backfill reinforcement proves instrumental in fortifying against potential structural vulnerabilities. Discover how this advanced methodology secures longevity and elevates the resilience of construction projects, ensuring enduring stability and performance.

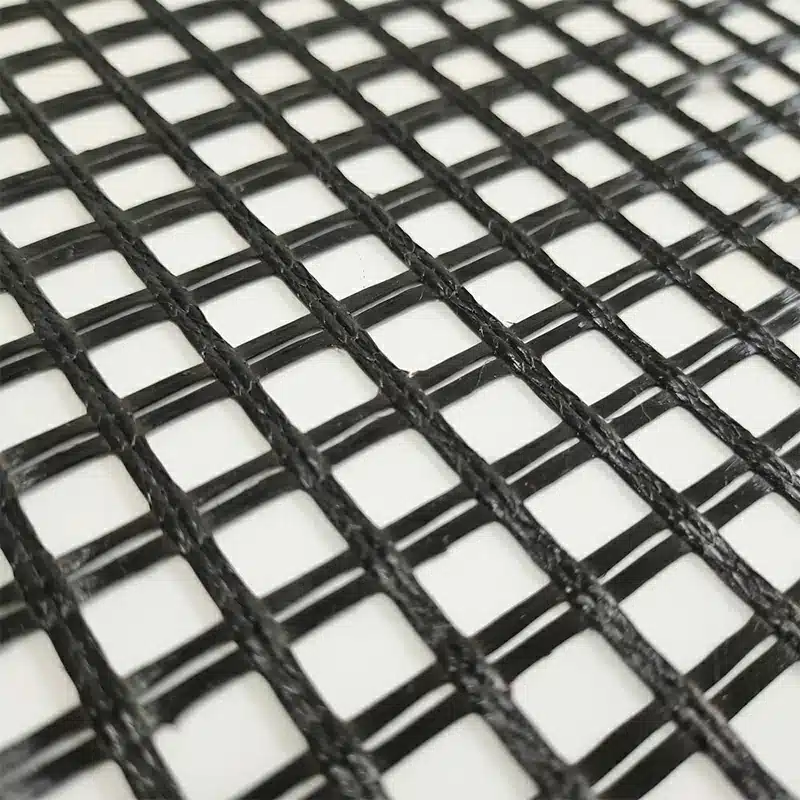

Yes, geogrids are extensively used for reinforcement in civil engineering and geotechnical applications. These geosynthetic materials are specifically designed to improve the structural performance of soil by providing tensile strength and distributing loads more evenly. Geogrids are commonly applied in retaining walls, roadways, slopes, embankments, and foundation systems. In these settings, they enhance load-bearing capacity, reduce differential settlement, and improve overall stability. Their open-grid structure allows for effective interaction with surrounding soil or aggregate, creating a composite system that resists deformation under load. Depending on the project requirements, uniaxial, biaxial, or triaxial geogrids may be selected to address specific directional stresses. In essence, geogrids serve as a reliable, cost-effective reinforcement solution that strengthens soil structures and extends infrastructure lifespan.

When designing geogrid-reinforced backfill for integral bridge abutments, several key factors should be carefully considered:

In summary, geogrid reinforcement provides significant advantages for the backfill of integral bridge abutments, including improved stability, reduced settlement, minimized lateral earth pressures, enhanced load distribution, erosion resistance, construction efficiency, and long-term durability. These benefits make geogrid-reinforced backfill a reliable and widely adopted solution in modern bridge construction and engineering design.

Not necessarily. The need for geogrid reinforcement in a retaining wall depends on several factors such as the height of the wall, the soil conditions, the type of material used for the wall, and the expected loads it will bear.

For shorter retaining walls (typically under 4 feet), geogrid reinforcement might not be necessary if the soil conditions are stable and the wall is properly designed and constructed. However, for taller walls or walls built in unstable soil conditions, geogrid reinforcement is often recommended to provide additional stability and prevent potential failure.

In essence, while geogrid reinforcement can enhance the stability and durability of a retaining wall, its necessity depends on the specific circumstances of each project.

Backfilling, the process of replacing soil into a hole or trench after excavation, can present several challenges:

Addressing these challenges requires careful planning, proper materials, and skilled execution to ensure the stability and longevity of the structure or area being backfilled.

In conclusion, integrating geogrid backfill reinforcement in structural projects offers a reliable solution to mitigate these problems, ensuring stability, longevity, and enhanced structural integrity.

We’ll respond as soon as possible(within 12 hours)

WhatsApp us