LLD250

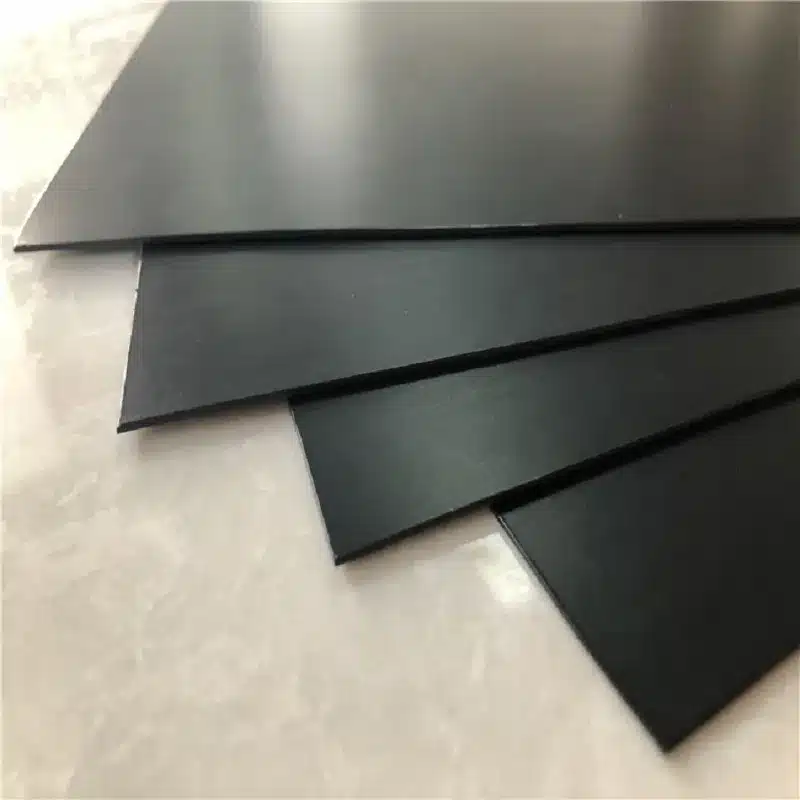

GeofanMeb LLD Geomembrane

- Our LLD range of geomembranes are manufactured from low linear density polyethylene and are tested in accordance to current ASTM standards.

- LDPE gives a more flexible geomembrane with excellent chemical resistance and high UV degradation resistance.

LLD250

General Application(s):

- Liquid containment features such as artificial lakes

- Irrigation channels and storage ponds

- Wrapping of subsurface storage tank systems

- Our roll width of 7m, lowers the installation cost by limiting unnecessary material overlapping wastage, reduced welding and increased speed of application

| Property | Test Method | Unit | Frequency | Minimum Value |

|---|---|---|---|---|

| Thickness (minimum average) | ASTM D 5199 | mm | Every roll | 2.50 |

Lowest individual reading (-10%) | ASTM D 6637 | 2.25 | ||

Density | ASTM D 1505 | g/cc | 90,000Kgs | 0.939 |

Tensile Properties (each direction) | ASTM D 6693,TypeIV | 9,000Kgs | ||

Strength at Break | Dumbell,2ipm | N/mm | 66 | |

Elongation at Break | G.L. 2.0 in (51mm) | % | 800 | |

2% Modulus(max) | ASTM D 5323 | N/mm | E.M.B | 1050 |

Tear Resistance | ASTM D 1004 | N | 20,000Kgs | 250 |

Puncture Resistance | ASTM D 4833 | N | 20,000Kgs | 620 |

Axi-Symmetric BreakResistance Strain | ASTM D 5617 | % | 30 | |

Carbon Black Conten | ASTMD1603*/4218 | % | 9,000Kgs | 2 |

Carbon Black Dispersion | ASTM D 5596 | 20,000Kgs | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | |

Oxidative Induction Time | ASTMD 3895,200℃ ,1 atm | min | 90,000Kgs | 100 |

Oven Aging at 85℃ | ASTM D 5721 | |||

Standard OIT, retained after 90days | ASTM D 3895 | E.M.B | 35 | |

UV Resistance High Pressure OIT, retained after 1600 hours (min.avg) | ASTM D 5885 | E.M.B | 35 |

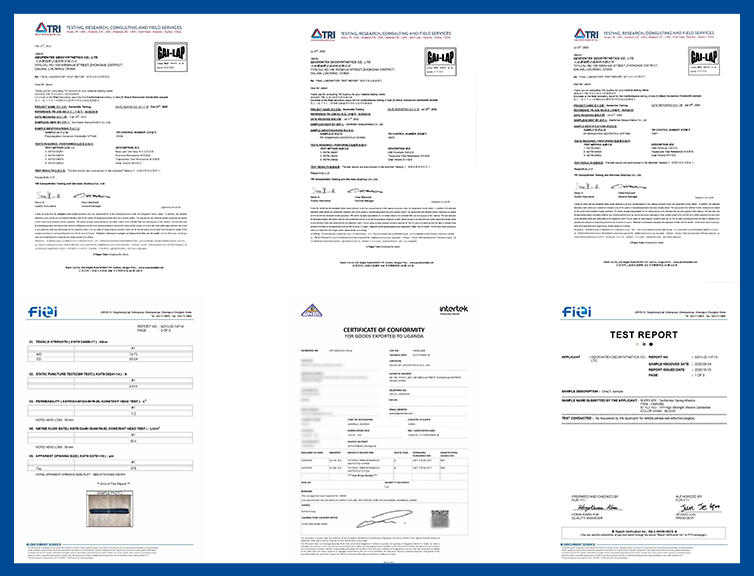

- (1) The above values are on an average basis, the data was obtained from in-house test laboratories, National test institutes, and international test institutes. Geofantex Geosynthetics keeps the right of data changes and the final explanation right.

- (2) Liability Exclusion: This publication should not be construed as engineering advice. While the information contained here is accurate to the best of our knowledge, Geofantex Geosynthetics does not warrant its accuracy or completeness. The only warranty made by Geofantex Geosynthetics for its products is outlined in our Product Test Report accompanies our shipment of the products, or such other written warranty as may be agreed by Geofantex Geosynthetics and the customer.

- (3) Geofantex Geosynthetics specifically disclaims all other warranties, express or implied, including without agreement by Geofantex Geosynthetics and the customer. Geofantex Geosynthetics specifically disclaims all other warranties, express or implied, including without limitation, warranties of merchantability or fitness for a particular purpose, or arising from the provision of samples, a course of dealing, or usage of trade.

LLD 250 Shipping and packaging information

| Roll Length(m) | Roll Width(m) | Approx Load Q’ty per 40’ HC(㎡) |

|---|---|---|

| 84 | 1-7 | 11172 |

Certificate

LLD 250 Industry Product Equivalents

ACF ACF N031, ADS ADS 0311T, BP-Amoco Amoco 4535, Carthage Mills FX-30HS, Contech C-31NW, Crown Resources/TNS Crown R031, Dalco Daltex 1031, EXXON Exxon GTF-125, Hanes Geo TerraTex N03, L&M Supply LM 310, Maccaferri MacTex N11.1, Mirafi Mirafi 135N, Propex Geotex 311, Synthetic Industries SI 311, Skaps Skaps GT131, Thrace-LINQ LINQ 120EX, Willacoochee Industries WINfab 310N

This information is provided for reference only and is not intended as a warranty or guarantee. US Fabrics assumes no liability in connection with the use of this information.