+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geosynthetics and Their Applications(Part 2)

1. Reinforcement

Common reinforcement materials: geogrids, geotextiles and georeinforced tapes, etc.

There are two main types of reinforcement in highway engineering:

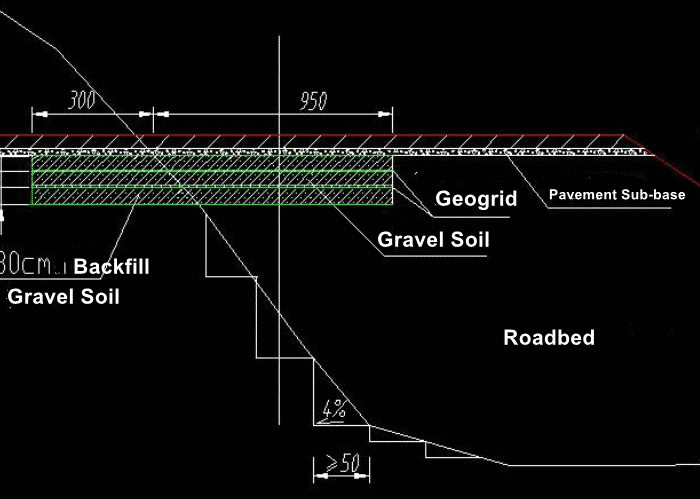

①The stability of the embankment is insufficient. In order to improve the stability of the embankment and control the settlement of the embankment, geosynthetics are used for embankment reinforcement;

②In order to reduce the uneven settlement between the subgrade and the structure, the subgrade on the back of the platform is reinforced with geosynthetics.

(1) Reinforcement mechanism

The material is placed in the soil as required, and the lateral movement of the soil is restricted by the interfacial friction between the material and the surrounding soil, so that the modulus of the soil is increased and the integrity is enhanced to increase the bearing capacity of the soil. Reinforced soil engineering: At present, reinforced soil has been widely used in soft soil foundations to strengthen building retaining walls, construction of steep slopes, shallow foundation foundations, bridge abutments, road crack prevention reinforced soil retaining walls, etc.

Most of them are based on the interaction of the two materials at the interface between the reinforcement and the soil. The popular view (around friction):

①The reinforcement adds a frictional force to prevent lateral deformation in the soil;

② Reinforcement increases soil cohesion;

New point of view:

Tension Membrane Theor

Stress field and displacement field change

Indirect Influence Band Theory

deep base effect

(2) Reinforcing material properties

Tensile strength and stress-strain relationship (elongation) of bars

Tensile stiffness of bars (creep and stress relaxation)

Roughness of reinforcement and occlusal performance with soil (wear resistance)

Resistance to temperature, aging and durability of bars

The failure mode of the reinforcement: fracture, pull-out, excessive tensile deformation

.png)

A.png)

2. Filtration and drainage

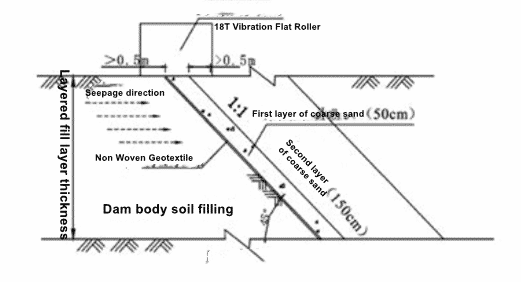

Filtration: prevent the massive loss of soil particles during the drainage process of geotechnical structures;

Drainage: Drain excess water to maintain soil stability;

Filtration and drainage are often required at the same time to enhance soil resistance to infiltration damage.

(1) Filtration mechanism of geotextiles

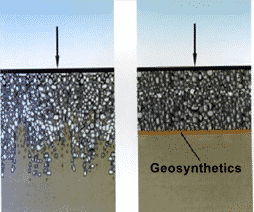

When the water in the soil flows through the geotextile, the water can pass through smoothly, but the soil particles are blocked. This phenomenon is called filtration or reverse filtration.

The main factors affecting the design of geotextile filter:

①Types and characteristics of geotextiles;

②The nature and state of the protected soil (internal stable soil and internal unstable soil, cohesive soil and sandy soil)

③ characteristics of water flow (dynamic flow and static flow, one-way flow and two-way flow);

④The construction quality of the geotextile and the contact surface of the soil layer;

⑤Other external conditions (such as the downstream drainage material of the reverse filter layer)

(2) Drainage

Drainage, the ability of a material to allow water to drain along its interior. It is used as an alternative to traditional drainage material sand and gravel. Nonwoven geotextiles, composite drainage materials, drainage pipes and plastic drainage have this feature.

Commonly used drainage materials: non-woven geotextile, plastic drainage pipes, plastic drainage belts, geonets, capillary drainage belts, flexible drainage pipes, quick-draining dragons, etc.

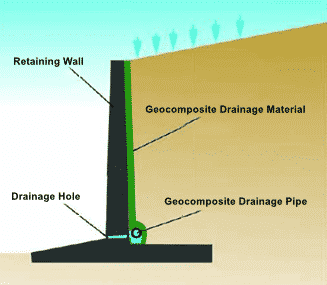

The figure below shows the use of non-woven geotextile or composite drainage material on the back of the retaining wall to drain groundwater to the drain pipe, and then drain it away by the drain pipe.

Set purpose:

(1) Accelerate soil drainage and consolidation and improve soil performance;

(2) Conduct the seepage water in the soil and reduce the seepage pressure;

(3) Reduce the infiltration line in the soil and increase the stability of the soil

(3) Separation

Separation, the function of separating two different materials so that they do not mix.

For example: separating the crushed stone under the railway track from the fine-grained soil of the foundation. The materials used for isolation are often geotextiles or geomembranes. The integrity and stability of the media and structure are maintained through isolation.

(4) Waterproof

Waterproofing, the use of materials to block liquid (water) body or prevent its loss I LI .,. role. Commonly used anti-seepage materials are geocomposite membranes.

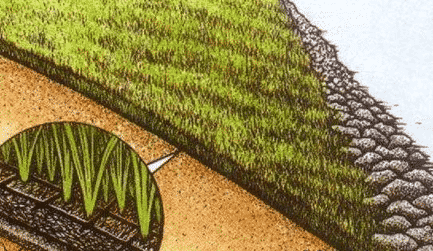

3. Subgrade protection

Protection, subgrade protection mainly includes slope protection and scour protection, using suitable materials to protect rock and soil from damage caused by environmental influences, such as laying geotextiles on the bank slopes of dams to resist water scouring; For soil antifreeze and landscape greening, etc.

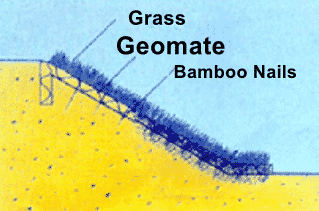

Commonly used protective materials include geotextiles, geotube, geonets, and three-dimensional geomate.

(1) Slope protection

Protect the subgrade slope surface from rain erosion, slow down the influence of temperature difference and humidity change, prevent and delay the evolution process of weathering, crushing and denudation of the soft rock and soil surface, and ensure the overall stability of the subgrade.

Commonly used soil slope stretch mesh turf, fixed grass seed cloth, grid fixed seeding; rock slope geonet, geogrid, etc.

(2) Anti-scour effect

Prevent the erosion, slapping and elutriation of the subgrade by water flow, or prevent the loss of fine-grained filler in the subgrade when the water level drops suddenly.

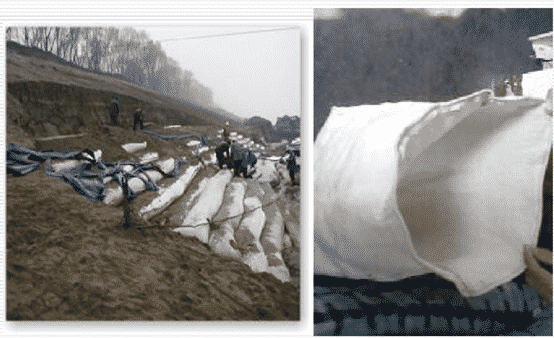

Commonly used geotextile soft sink, geomembrane bag, etc.

Geotextile soft sinking slope protection: a slope protection structure with rock or precast concrete as the load on the geotextile.

It is suitable for underwater engineering and the riverbed and bank slope soil surface where scour is expected.

Geomembrane bag for slope protection: The geomembrane bag is a double-layer fabric bag filled with fluid concrete or cement mortar or diluted concrete, which forms a high-strength and high-rigidity hardened slab after solidification. It is suitable for scouring protection of subgrade and water-facing slopes in mud, pond and small lake areas.

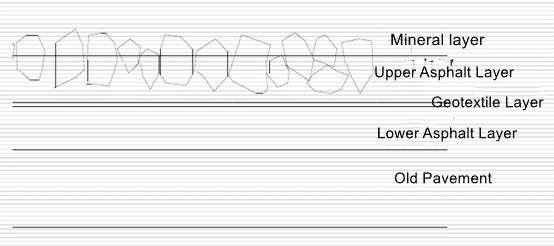

(4) Prevention of pavement cracks

Inhibit the upward expansion of cracks caused by the shrinkage of the semi-rigid base, reduce the rutting of the asphalt pavement, prevent and delay the reflection cracks of the asphalt overlay laid on the old cement concrete pavement, and improve the base and sub-base in the semi-rigid base asphalt pavement. fatigue life.

The main geosynthetic materials used for the prevention and control of pavement cracks are: fiberglass mesh, geotextile, etc.

In general, the reinforcement technology of geosynthetics has developed rapidly and has been widely used in engineering practice.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)