+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

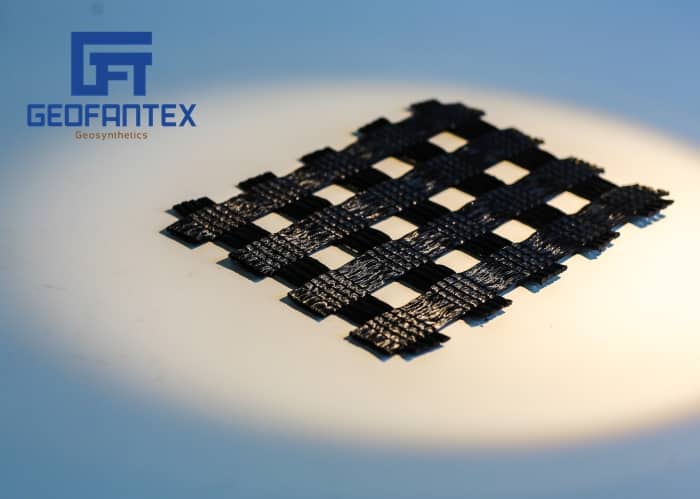

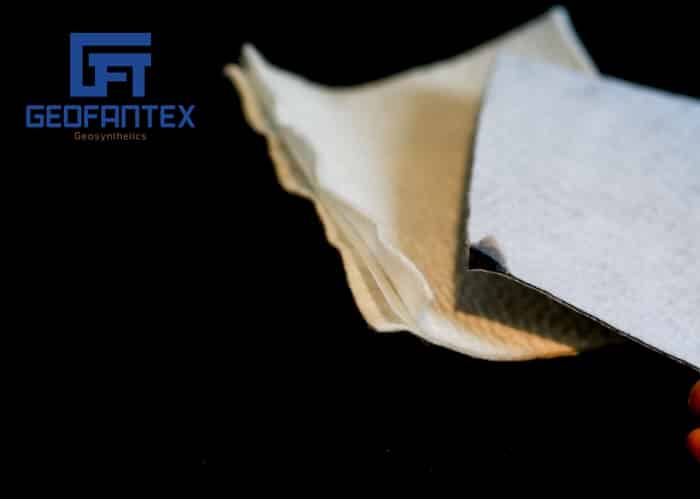

Geotextiles play a vital role in modern infrastructure projects, providing soil stabilization, reinforcement, and improved drainage on roadbeds, railways, and tunnels. Correct geotextile installation ensures durability, reduces maintenance costs, and enhances the overall lifespan of civil engineering structures. Understanding the proper laying method of geotextiles is crucial for engineers, contractors, and project managers.

Importance of Geotextile Laying on Roadbeds

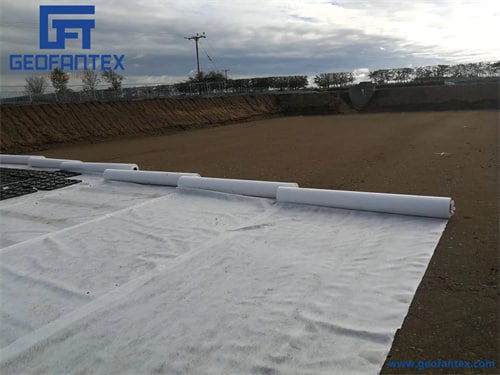

In road construction, geotextiles are primarily used to separate subgrade soil from aggregate layers, prevent rutting, and enhance load distribution. The proper laying method involves:

- Surface Preparation: Clear debris, vegetation, and loose soil. Ensure the subgrade is leveled and compacted.

- Orientation and Alignment: Roll out the geotextile along the road alignment, ensuring it covers the entire width of the subgrade.

- Seam Overlap: Maintain a minimum overlap of 300 mm between adjacent rolls to prevent soil migration and maintain integrity.

- Fixation: Use stakes, pins, or temporary weights to keep the geotextile in place before laying aggregates.

Correct installation prevents roadbed deformation, reduces maintenance, and prolongs pavement life.

Geotextile Installation on Railways

Railways require high structural stability to support dynamic loads from trains. Geotextiles enhance ballast stability and drainage. The railway geotextile laying method includes:

- Subgrade Preparation: Remove loose material and level the track foundation.

- Geotextile Placement: Roll geotextile along the track direction. Avoid folds or wrinkles that could compromise drainage.

- Overlap and Securing: Overlap adjacent sheets by 200–300 mm. Use pins or ballast to hold the geotextile in position.

- Ballast Installation: Place ballast over the geotextile gradually, avoiding sudden impacts that could damage the fabric.

Proper geotextile installation minimizes track settlement, maintains ballast structure, and improves drainage efficiency.

Geotextile Laying in Tunnels

Tunnels often encounter high groundwater pressure, requiring geotextiles to aid in drainage and soil stabilization. The tunnel geotextile installation method includes:

- Surface Cleaning: Remove loose soil or rocks and ensure the tunnel lining is ready for geotextile placement.

- Layering: Lay geotextile sheets along the tunnel lining, overlapping edges by at least 200 mm.

- Fixation: Attach geotextiles using anchors or temporary supports to prevent displacement.

- Drainage Integration: Combine geotextile with drainage mats or pipes to guide water away from the tunnel structure.

Properly installed geotextiles in tunnels reduce water pressure on linings, prevent soil erosion, and extend tunnel life.

The laying method of geotextiles on roadbeds, railways, and tunnels is a critical factor in infrastructure performance. Correct installation improves soil stabilization, enhances drainage, reduces maintenance costs, and increases the longevity of roads, railways, and tunnels. Selecting the appropriate geotextile type and following precise installation procedures ensures optimal results in civil engineering projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)