+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the realm of railway infrastructure, geocell technology is a game-changer. Geocells provide durability, stability, and cost-effectiveness for railway projects. They stabilize the ballast, reduce vertical and lateral stresses, and limit ballast movement. In this article, we’ll delve into the concept of geocells in railways, and their functions, and answer key implementation questions.

What is the concept of geocell?

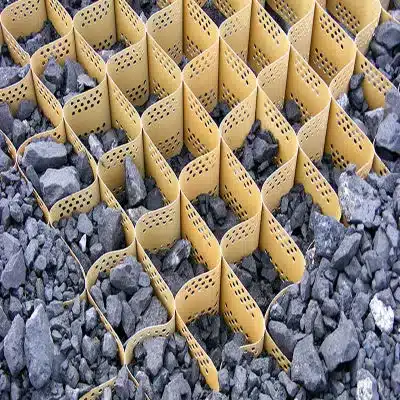

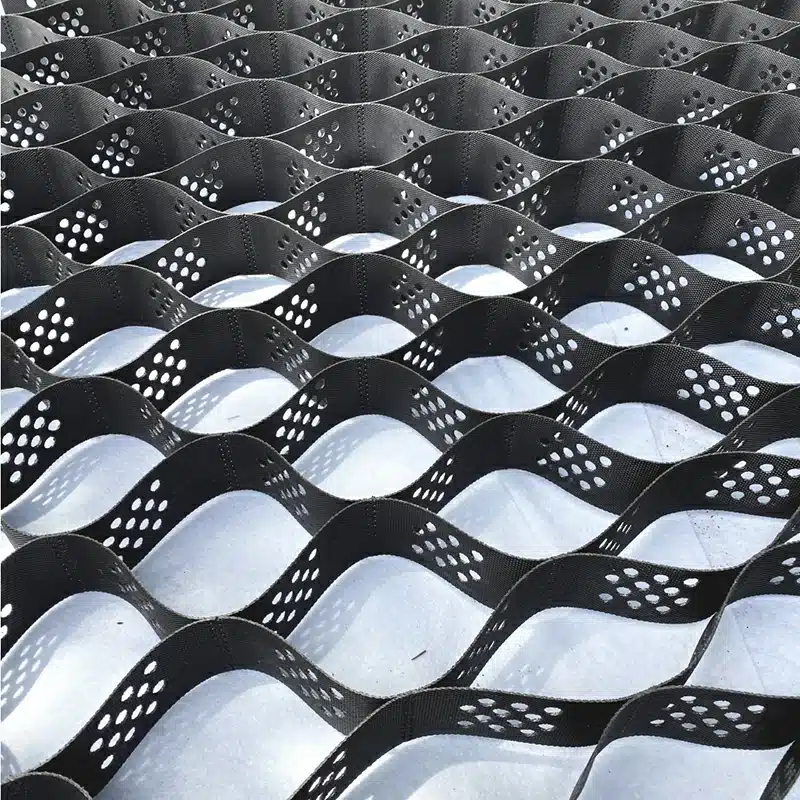

Geocell, or cellular confinement systems, is a durable material created from interconnected high-density polyethylene (HDPE) or polypropylene sheets, forming a three-dimensional honeycomb-like structure. These cells are filled with materials like soil, gravel, or aggregate based on the application. Geocells serve as a sturdy framework that reinforces the soil, providing stability and load-bearing capacity to railway tracks.

What is the function of a geocell?

- Load Distribution: Geocells spread the train’s load across a larger area, easing the strain on the subgrade soil. This prevents track settling and rutting, extending the railway infrastructure’s lifespan.

- Erosion Control: Geocells effectively reduce erosion, protecting railway embankments. Their three-dimensional design keeps soil in place during heavy rains, safeguarding track integrity.

- Slope Stabilization: Geocells secure slopes and embankments by containing soil, preventing erosion. This maintains slope shape and stability, averting landslides and derailments.

- Reduced Maintenance: Geocell technology minimizes long-term railway maintenance needs. Enhanced load-bearing capacity and track stability reduce the frequency of repairs and adjustments, saving time and money.

How is geocell technology environmentally friendly?

Geocell technology promotes sustainability in railway construction. It reduces the need for natural resources like gravel, as it allows for the use of local and recycled materials as infill. Additionally, by reducing maintenance requirements and the risk of erosion, geocells contribute to the preservation of the surrounding environment and reduce the carbon footprint of railway operations.

What are the key considerations when implementing geocells in railway projects?

Implementing geocell technology in railway projects involves several critical considerations:

- Geocell Selection: Choosing the right geocell type, material, and size is crucial to meeting the specific project requirements and load-bearing capacity.

- Installation: Proper installation techniques are vital to ensure that the geocells are securely placed and connected and that the infill materials are correctly compacted.

- Monitoring: Regular inspection and monitoring of the geocell-reinforced railway sections are necessary to detect any issues promptly and ensure their long-term performance.

- Compatibility: Geocell technology should be compatible with other railway components like ballast and track systems to ensure the seamless operation of the railway network.

In conclusion, geocell technology is a groundbreaking solution that significantly enhances railway infrastructure by improving load-bearing capacity, erosion control, and slope stabilization. With its environmental benefits and reduced maintenance requirements, geocells are becoming an indispensable component in modern railway construction and rehabilitation projects. Proper planning, installation, and monitoring are essential for successful implementation, making geocell technology a valuable addition to the railway industry.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)