+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Polyester Staple Fiber Nonwoven Geotextile – GeoFanTex

- Brand GeoFanTex® GFS

- Product origin China

- Delivery time 7-14 Days

- Supply capacity 40′ HQ/ 7 Days

Product Details

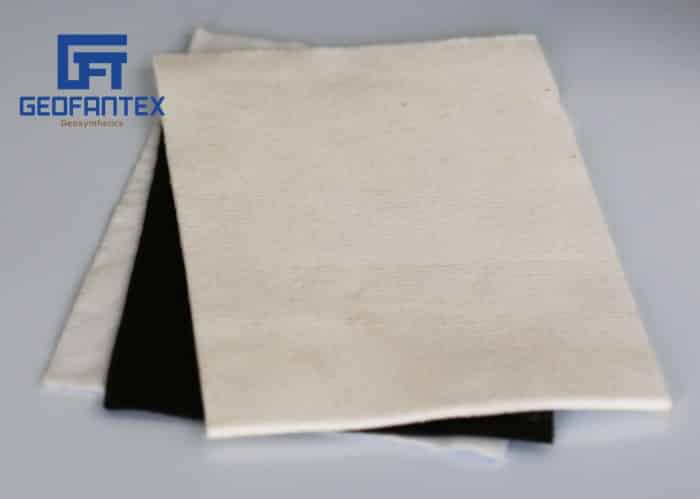

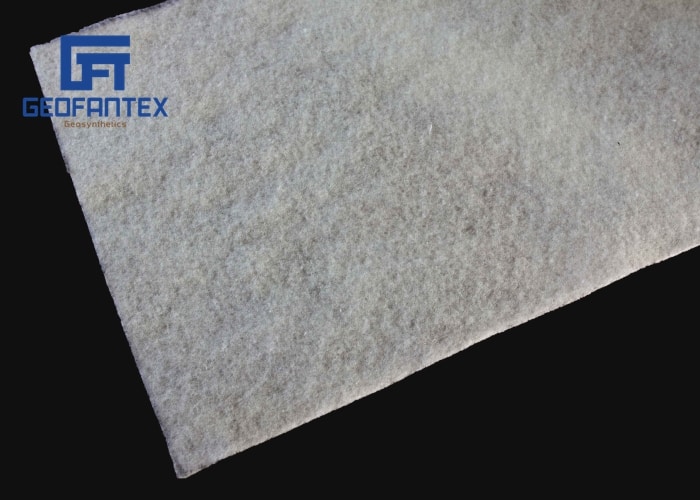

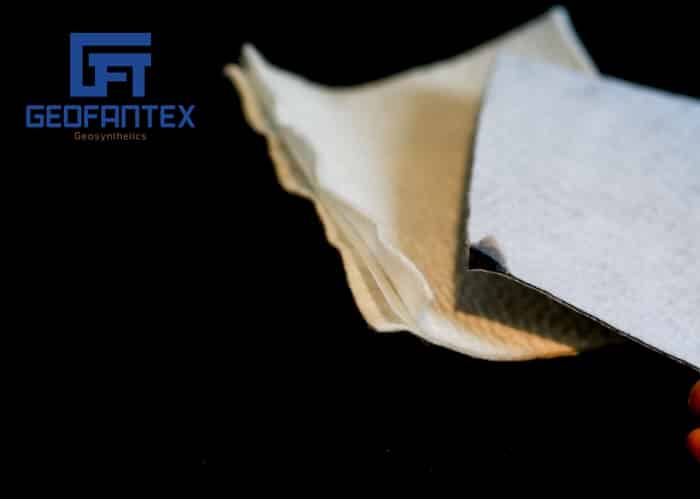

GeoFanTex® GFS Nonwoven Geotextiles are made from high-quality polyester staple fibers, providing excellent performance in soil stabilization, erosion control, and drainage. These geotextiles offer a range of functional properties, including mechanical strength, permeability, impermeability, and soil-tightness, making them ideal for various civil engineering applications.

Our data sheet provides information about the mechanical properties of GeoFanTex® GFS nonwoven geotextiles, but if you require details about permeable properties, loading quantities, or other specific information, we can provide this to you upon request. Choose GeoFanTex® GFS nonwoven geotextiles for superior quality and reliable performance in your civil engineering projects.

(* Geofantex Geosynthetics can produce GeoFanTex® GFS according to your requirement in constructions, MINIMUM ORDER QUANTITY: 20’ft Container)

Geotextile Speicifciations

| Properties | Standard | Unit | GFS 100 | GFS 150 | GFS 200 | GFS 250 | GFS 300 | GFS 350 | GFS 400 | GFS 450 | GFS 500 | GFS 600 | |

| Tensile Strength | ASTM D 4595 | M T | KN/m | 3.6 4.5 | 4.5 6.2 | 7.5 10.0 | 10.0 12.5 | 13 16 | 14.0 17.5 | 16.4 20.5 | 18.0 22.5 | 20 25 | 28 32 |

| Tensile Elongation | ASTM D 4595 | M | % | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Grab Strength | ASTM D 4632 | M T | N | 188 260 | 258 326 | 369 594 | 420 696 | 760 875 | 788 920 | 907 1043 | 967 1128 | 1045 1259 | 1245 1610 |

| Grab Elongation | ASTM D 4632 | M | % | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

For more properties please contact Geofantex Geosynthetics or send an email to info@geofantex.com

| Properties | Standard | Unit | GFS 800 | GFS 1000 | GFS 1200 | GFS 1400 | GFS 2000 | |

| Tensile Strength | ASTM D 4595 | M T | KN/m | 40 52 | 55 61 | 59 64 | 65 70 | 91 99 |

| Tensile Elongation | ASTM D 4595 | M | % | 50 | 50 | 50 | 50 | 50 |

| Grab Strength | ASTM D 4632 | M T | N | 2019 2731 | 3271 3622 | 3351 3812 | 3509 4047 | 4513 5279 |

| Grab Elongation | ASTM D 4632 | M | % | 50 | 50 | 50 | 50 | 50 |

For more properties please contact Geofantex Geosynthetics or send an email to info@geofantex.com

Geotextile Advantages

The light Polyester Staple Fiber Nonwoven Geotextile (GeoFanTex® GFS) has a filter and separation function, the main properties of heavy PET Staple Fiber Nonwoven Geotextile ( GeoFanTex® GFS ) for reinforcement are Strength, stiffness, and the conservation of these properties during the life cycle of construction.

1. Geotextile For Filtration and Separation

Polyester Staple Fiber Nonwoven Geotextile ( GeoFanTex® GFS) provide superior hydraulics and soil retention, making them ideal for filtration in subsurface drainage systems. PET Staple Fiber Nonwoven Geotextile ( GeoFanTex® GFS ) have conservation of the cycle life of road, also reduces the overall thickness of the road structure by requiring less aggregate during construction. Bank protection with a filter construction.

2. Geotextile Fabric Reinforcement

Polyester Staple Fiber Nonwoven Geotextile(GeoFanTex® GFS ) is commonly installed in reinforcement and protection for the natural ground and embankment on the natural ground with low bearing capacity. Steep slope structure.

Applications of Non Woven Geotextile

- Separation: Nonwoven geotextile to separate construction materials (such as soil and sand, sand and gravel, soil and concrete, etc.) with different physical properties (large grain diameter, distribution, consistency, density, etc.) The two kinds of materials are not lost or mixed, the overall structure and function of the materials are maintained, and the load-bearing capacity of the structure is strengthened.

- Filtration: When the water flows from the fine soil layer into the coarse soil layer, the good air permeability and water permeability of the needle punched geotextile is used to pass the water flow, and the effective interception of soil particles, fine sand, small stones, etc., to maintain water and soil Engineering stability.

- Drainage: Needle punched geotextile is a good water-conducting material. It can form a drainage channel inside the soil and discharge excess liquid and gas in the soil structure.

- Reinforcement: Use acupuncture geotextiles to enhance the tensile strength and deformation resistance of the soil, increase the stability of the building structure, and improve the soil quality.

- Protection: Effectively spread, transfer or decompose concentrated stress to prevent soil from being damaged by an external force.

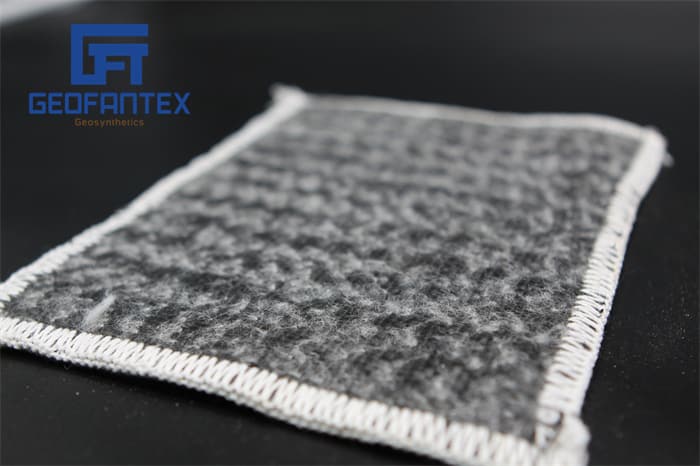

- Geocomposite: Sealing Needle-punched geotextiles fabric cooperates with other materials (mainly asphalt or plastic film) to form an impervious barrier in the soil layer. (For road resurfacing, etc.)

Geofantex Geosynthetics have to make a series of guarantee for our products both plant processing and selling out to our customers. Selling to you is the first step, the service, and guarantee is our task. Geofantex Geosynthetics have an ISO Certificate to guarantee the raw material, the product processing, and the end product. From receiving your order to replacement and installation of the products, we have solved the problems in time if you need, whatever the quality and technics guideline or suggestions. Our company has been committed to supplying high-quality products with reasonable price and delivery in time.

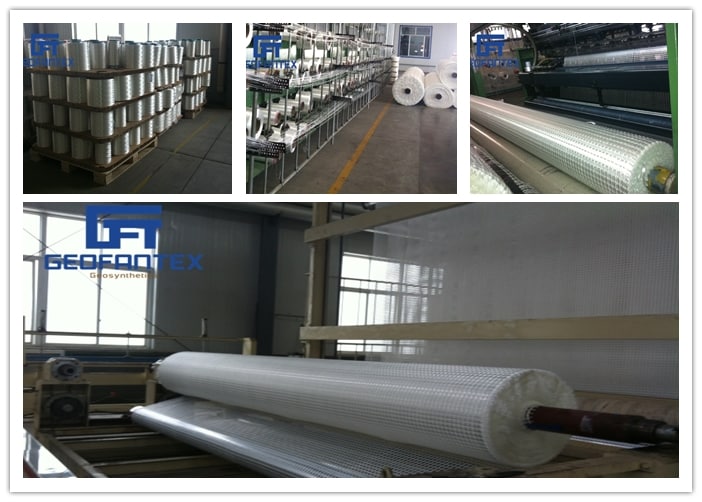

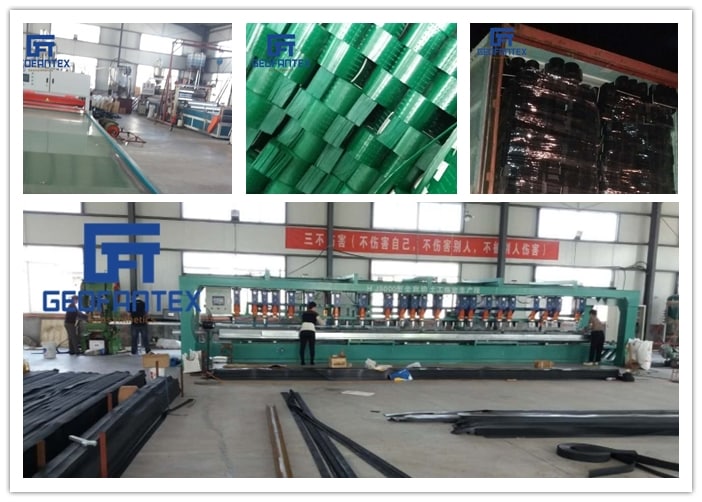

MANUFACTURING QUALITY ASSURANCE

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at the factory. GEOFANTEX maintains a high level of quality and up-to-the-minute results on finished products through a fully equipped, well-staffed, dedicated laboratory existing in each of the manufacturing facilities. Each facility follows the same guidelines for evaluating the quality of GEOFANTEX products and is capable of adapting to market-driven requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define an implementation of basic manufacturing quality assurance (MQA) procedures necessary to ensure consistent production of quality products supplied to the geosynthetic market. Note that at this time, these procedures are limited to polyester staple fiber nonwoven geotextile.

B. Scope

In order to achieve GEOFANTEX’s stated purpose, a rigorous set of minimum standards and an effective test program to assure compliance have been established. These procedures and requirements are frequently reviewed and adjusted to assure compliance with current market demands and/or predetermined project specifications. These procedures assure that raw materials and process parameters are controlled to provide products complying with GEOFANTEX’s pre-defined minimum characteristics.

PRODUCT IDENTIFICATION AND DOCUMENTATION

A. Roll Numbering

Each roll of geotextile is assigned a unique roll number. The Quality Assurance Laboratory maintains records documenting the raw materials and resulting product quality information.

B. Approval Procedure

Results for each tested roll of the product are checked against both GEOFANTEX China standard and customer specifications for compliance. The Quality Assurance Laboratory approves those materials that meet these requirements for shipment.

C. Non-Conformance

Material that does not meet GEOFANTEX minimum standards is given a roll number but is rejected and not placed into inventory. The material is identified as scrap and will not be utilized. Material that meets GEOFANTEX minimum standards but does not meet a stricter customer specification is not allocated to that customer but is placed into inventory as GEOFANTEX standard material.

D. Documentation

Individual Quality Assurance Certificates are generated and supplied for each roll of needle punched nonwoven geotextile product to include all relevant quality assurance information about the material(s).

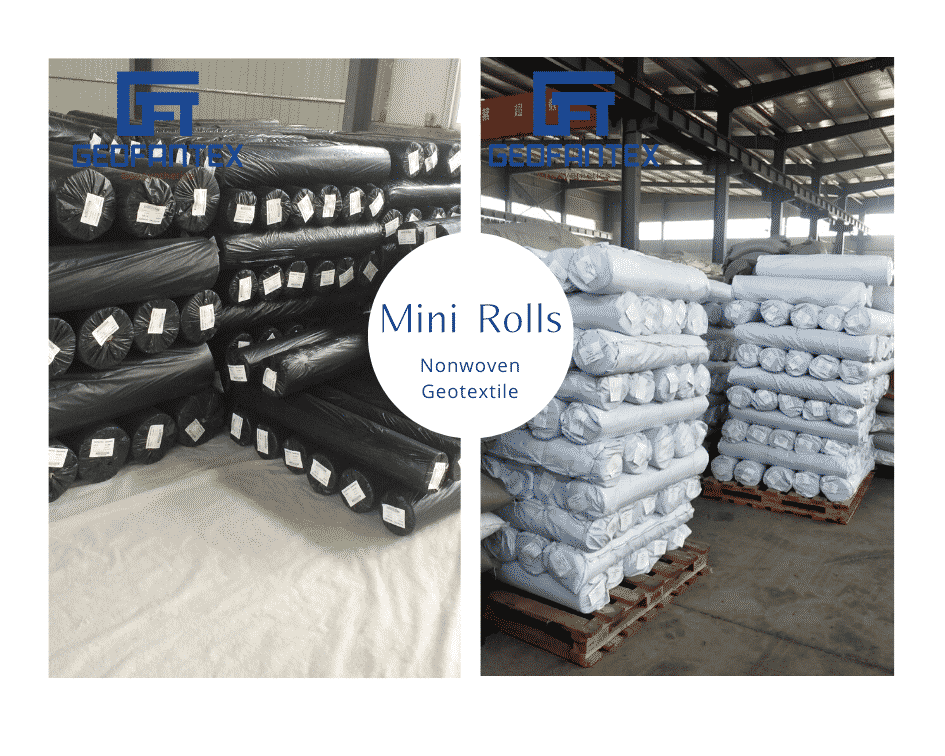

Geofantex Geosynthetics have a series of package and delivery service working procedures. Geofantex Geosynthetics have supplied thousands of containers to Latin America, North America, Southeast Asia, and developed countries, and Africa within the past ten years. We provide the package of products with the rolls, pots, bags, sheets, or your requirement in orders. Our company has been committed to supplying high-quality products with reasonable price and delivery in time. Delivery one 40’HQ within 7 – 10 days. And we have an obligation in increasing loading quantity and make you save the freight costs maximally. We supply the products by plane, by sea and land carriage to any regions or any countries of the worldwide, even the door-to-door service.

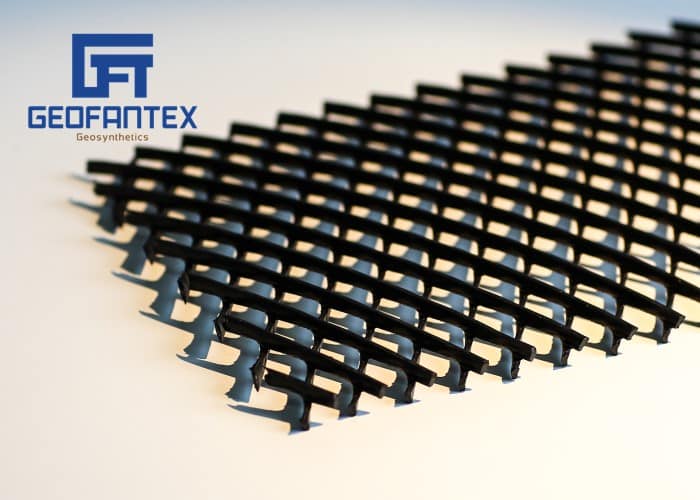

| SEPARATION | REINFORCEMENT | FILTRATION | DRAINAGE | WATERPROOF | PREVENTION | POLLUTION PREVENTION | PROTECTION | CONSOLIDATE | |

| GEOTEXTILE | √ | √ | √ | √ | √ | √ | |||

| GEOMEMBRANE | √ | √ | √ | ||||||

| GEOGRID | √ | √ | |||||||

| GEONET | √ | ||||||||

| GEOTUBE | √ | ||||||||

| GEOCELL | √ | √ | |||||||

| GCL | √ | √ | |||||||

| GEOCOMPOSITE | √ | √ | √ | √ | √ | √ | √ | ||

| GEOCONCRETE BLANKET | √ | √ | √ | ||||||

| Drainage Board B | √ | √ | √ | √ | |||||

| Storage and Drainage Board | √ | √ | √ | √ | |||||

| Grass Paver | √ | √ | √ | √ | √ | √ | √ | ||

| Macmat | √ | √ | √ | √ | √ | √ | √ | ||

| GeoFanTex®GD 2L | √ | √ | √ | √ | √ | √ | |||

| GeoFanPipe® FP | √ | ||||||||

| GeoFanDrain® BC | √ | √ | √ | ||||||

| GeoFanPipe® DCP | √ | √ | |||||||

| GeoFanTRM® Geomantles | √ | √ | √ | √ | √ |

General Installation Guidelines

Geofantex non-woven geotextiles perform the functions of separation and reinforcement. They are referred to by tensile strength and offer a very high load capacity. While woven fabrics are relatively impermeable and won’t provide good drainage, their high compressive strength makes them an ideal choice for roads, parking lots, etc.

The successful use of non-woven geotextiles in these applications requires proper installation. The basic steps of proper installation include:

Step 1:Subgrade Preparation

Level the subgrade to remove ruts, potholes etc. with a depth greater than 100mm.

Step 2:Laying The Geotextile

Roll out the geotextile over the prepared subgrade.

Step 3:Jointing Of Geotextile Layers

Overlap rolls 300–500 mm depending on subgrade. Geotextiles >200 g/m² can be welded by heating overlaps.

Step 4:Repair Of Damages (If Necessary)

In the case of damages occurring during installation, these have to be covered with a piece of nonwoven of the same quality. Such patches can be cut to size with a knife or with scissors.

Step 5:Placing Of The Sub-base Material

Trucks should not be driven directly over the geotextile: the aggregate should be back dumped. The required depth of the fill material depends on the bearing capacity of the subsoil but should not be less than 400 mm for low-bearing-capacity soils.

Step 6:Spreading

Spreading should be carried out with tracked plant (due to lower pressure soil contact pressure).

Geotextile Installation Guide

If you would like further information about the installation guide, please

Certificate

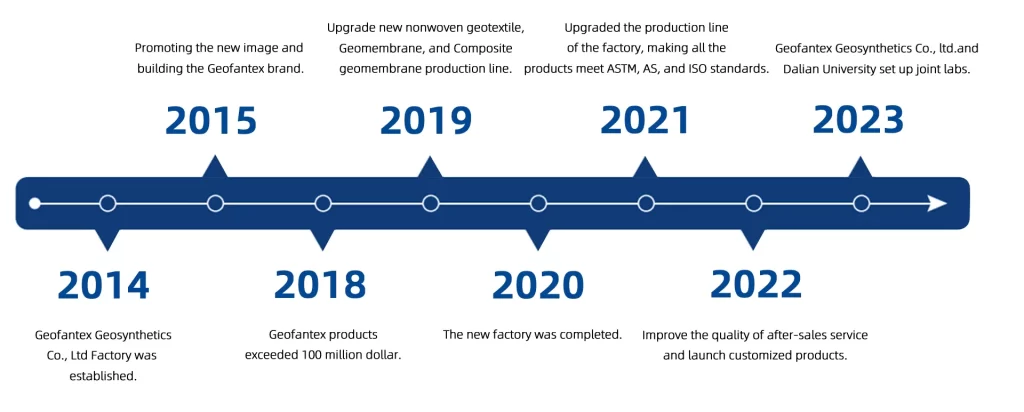

Development history of the company

Company Profile

Geofantex Geosynthetics Co., Ltd. is based in Dalian, a beautiful coastal city known for its excellent location and good transportation. Founded in 2014 with a registered capital of 5 million yuan, the company operates from an industrial park in Jinan, Shandong, covering over 50 acres. It features a modern office, advanced production equipment, and a skilled team in technical and management roles.

Geofantex has achieved ISO9001 and ISO14001 certifications and adheres to national standards to ensure product quality. Since its inception, the company has adopted advanced technologies and equipment, exporting products to regions like Australia, Canada, and Southeast Asia. Its export sales have reached significant figures, and customer feedback highlights our products’ stability, reliability, and cost-effectiveness.

The company leverages its innovative capabilities and market advantages, aiming to become a leading enterprise supported by national policies. Committed to “quality first” and “reputation first,” it emphasizes a people-oriented approach and values integrity, unity, and hard work. Geofantex seeks to collaborate with various engineering units to contribute to infrastructure development.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)