+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the realm of geotechnical engineering, materials like geonets and geogrids play pivotal roles in reinforcing soil, enhancing erosion control, and facilitating drainage. Geogrids, in particular, are plastics formed in a wide open, regular netlike structure, purpose-developed for the reinforcement of soil. This specific design allows them to interlock with soil particles, significantly enhancing the soil’s stability and load-bearing capacity. Despite their similar applications, these materials possess distinct characteristics and functionalities. This article delves into the nuances between geonets and geogrids, exploring their definitions, purposes, types, and lifespans, providing a comprehensive understanding for professionals and enthusiasts alike.

What is the difference between a Geonet and a Geogrid?

Geonets and geogrids are both types of geosynthetic materials used in various civil engineering and environmental applications, but they serve different purposes and have different structures.

Geonet:

- Geonets are typically made from polymer materials like high-density polyethylene (HDPE) or polypropylene.

- They consist of a series of interconnected parallel ribs or channels with openings or perforations between them.

- Geonets are primarily used for drainage applications, including landfill drainage, leachate collection, and subsurface drainage systems.

- They provide a pathway for the flow of liquids through the material while preventing the passage of soil particles.

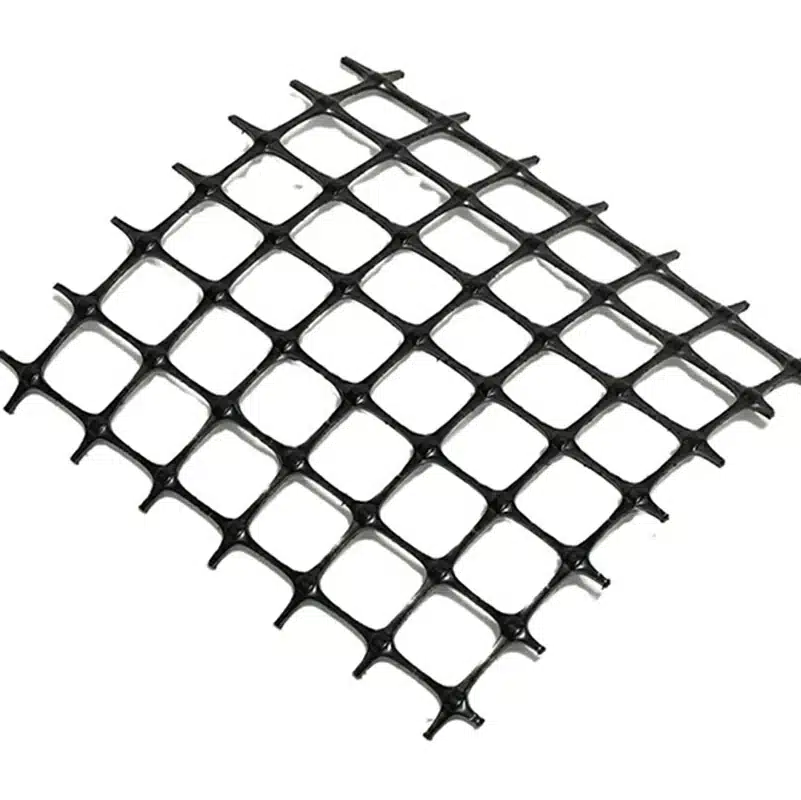

Geogrid:

- Geogrids are usually made from polymers (plastics), fiberglass, or steel.

- They are characterized by a grid-like structure with regularly spaced apertures or openings.

- Geogrids are used primarily for soil reinforcement applications, such as stabilizing retaining walls, steep slopes, and roadways.

- They improve the structural integrity of the soil by confining it and distributing loads more evenly, thereby reducing soil movement and increasing stability.

In summary, while both geonets and geogrids are geosynthetic materials used in civil engineering, geonets are used for drainage purposes, whereas geogrids are used for soil reinforcement.

What is the purpose of a Geogrid?

Geogrids serve several purposes in civil engineering and construction:

- Soil Reinforcement: Geogrids are used to reinforce soil, providing structural support to the soil mass. They distribute loads over a wider area, reducing the pressure on the soil and preventing soil movement or failure.

- Stabilization: They stabilize slopes and embankments by improving the bearing capacity of the soil. This helps prevent erosion and landslides, especially on steep slopes.

- Retaining Walls: Geogrids are often used in the construction of retaining walls to enhance their stability and strength. They reinforce the soil behind the wall, reducing the pressure exerted on the structure.

- Pavement Reinforcement: In road construction, geogrids are employed to reinforce the pavement layers, reducing rutting, cracking, and deformation caused by traffic loads. This extends the lifespan of the pavement and reduces maintenance costs.

- Erosion Control: Geogrids can also be used for erosion control in applications such as shoreline protection, riverbank stabilization, and stormwater management. They prevent soil erosion by stabilizing the soil surface and promoting vegetation growth.

Overall, geogrids are essential geosynthetic materials that contribute to the stability, durability, and sustainability of various civil engineering projects.

What are the three types of Geogrid?

Geogrids can be categorized into several types based on their manufacturing process and the direction of their strength, including Uniaxial, Biaxial, Triaxial (Triax®), and Geogrid-Geotextile Composites:

- Uniaxial Geogrids: These are designed to provide strength in one direction and are commonly used in retaining wall and slope stabilization projects. Their specific structure is ideal for applications where support is needed predominantly in a single direction.

- Biaxial Geogrids: Offering strength in two directions, biaxial geogrids are often utilized in roadway and pavement applications, where equal distribution of load in both directions is crucial. This bidirectional strength is essential for ensuring the stability and durability of the paved surfaces.

- Triaxial Geogrids (Triax®): With strength distributed in three directions, triaxial geogrids provide a more uniform reinforcement, making them suitable for a wide range of applications, including base reinforcement for roads, railways, and foundations. Their triaxial structure offers enhanced stability and support compared to uniaxial and biaxial types.

- Geogrid-Geotextile Composites: These innovative materials combine the reinforcement capabilities of geogrids with the separation and filtration functions of geotextiles. They are particularly useful in complex engineering projects where both reinforcement and drainage/separation are required.

This classification underscores the versatility of geogrids in addressing various geotechnical engineering needs, from simple reinforcement to complex stabilization and drainage requirements.

What is the lifespan of a Geogrid?

Typical Lifespan of a Geogrid

The lifespan of a Geogrid typically ranges from 50 to 100 years, depending on various factors.

Factors Affecting Longevity

- Material Quality: Geogrids made from high-density polyethylene (HDPE) or polypropylene (PP) tend to last longer due to their resistance to environmental degradation.

- Environmental Conditions: Exposure to UV radiation, chemical agents, and biological factors can reduce the lifespan. Geogrids buried in soil or covered to minimize UV exposure generally last longer.

- Installation Quality: Proper installation ensures the geogrid performs optimally and remains intact. Poor installation can lead to early failure due to physical damage or incorrect placement.

- Load and Stress: Constant heavy loads and dynamic stresses can wear down the geogrid over time. Geogrids under lower stress conditions typically last longer.

Ways to Extend Durability

- Proper Installation: Follow manufacturer guidelines strictly. Ensure correct tensioning and anchoring during installation.

- Protective Measures: Use protective coatings or coverings to shield from UV radiation. Employ geotextiles or other materials to protect from chemical exposure.

- Regular Maintenance: Inspect periodically for signs of damage or wear. Address any issues promptly to prevent further degradation.

- Choosing Quality Products: Select geogrids from reputable manufacturers known for durable and high-quality materials.

By considering these factors and implementing protective measures, the lifespan of a geogrid can be maximized, ensuring long-term performance and stability in various applications.

Understanding the difference between geonets and geogrids is crucial for professionals in geotechnical engineering and related fields. While both materials serve to improve soil stability and control erosion, their specific applications, structures, and functionalities set them apart. Geonets are primarily used for drainage, whereas geogrids are essential for soil reinforcement, available in various types to suit different engineering needs. Remarkably, geogrids have a potential lifespan of about 100 years, representing a long-term solution for enhancing the durability and stability of civil engineering projects. This impressive longevity underscores the value of geogrids in providing sustainable, effective reinforcement over time.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)