+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the realm of environmental conservation and construction, geotextile silt fences stand as unsung heroes, playing a pivotal role in soil stabilization and sediment control. These innovative barriers are not just a testament to human ingenuity in harnessing technology for ecological benefits but also a key player in maintaining the delicate balance between development and nature preservation. This article delves into the fabric of geotextile silt fences, exploring their purpose, installation nuances, and their unique ability to allow water passage while holding back soil particles.

What is the fabric for a silt fence?

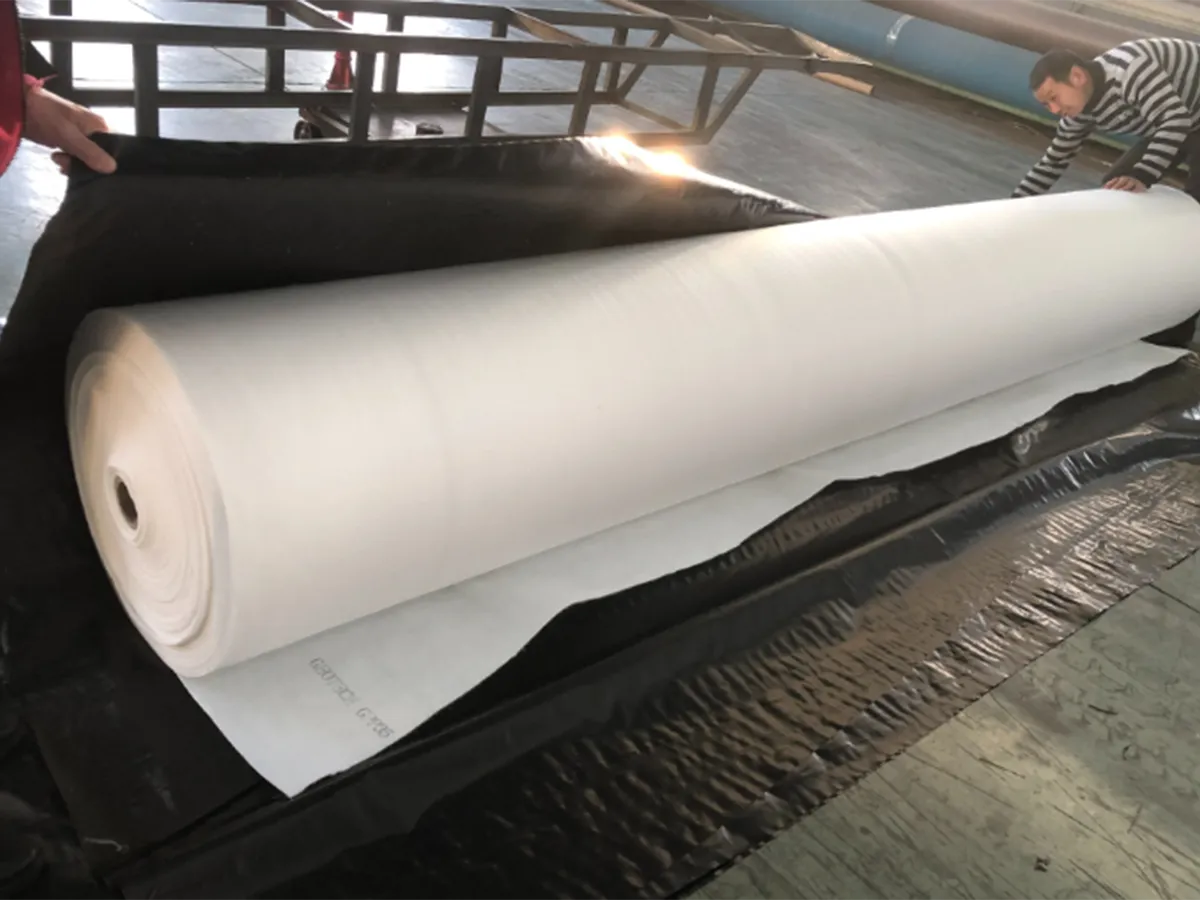

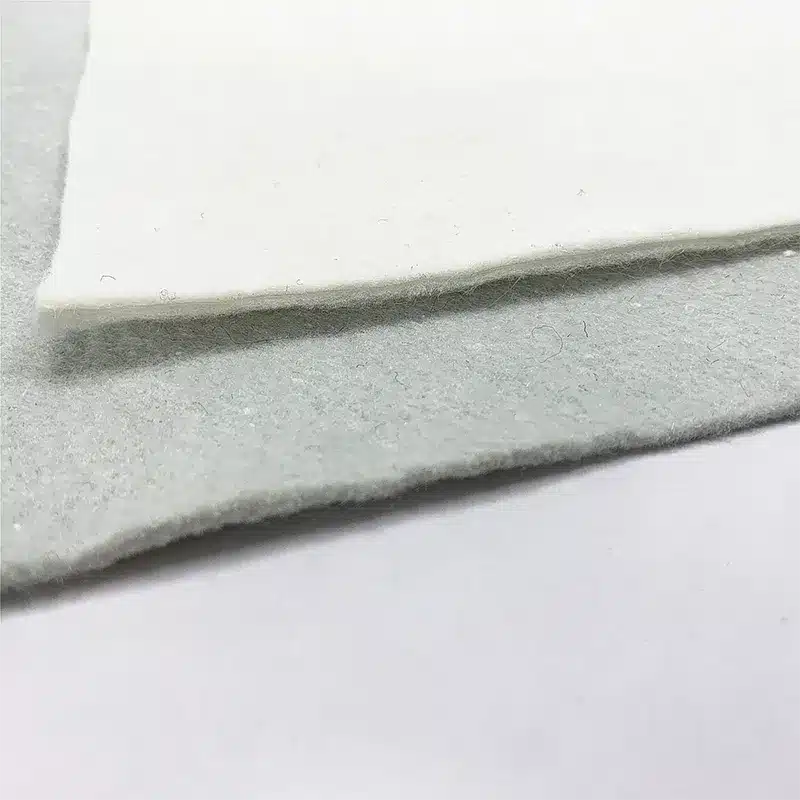

Geotextile fabric, also known as synthetic filtration fabric, typically geotextile filter fabric, is the primary material used for silt fences. This permeable textile is crafted from synthetic fibers through a variety of processes including weaving, needle-punching, or heat-bonding. Engineered specifically to retain soil particles while permitting water to filter through, it stands as an optimal solution for erosion control and sediment management in construction sites and areas prone to land disturbance. The durability and superior filtration capabilities of this synthetic filtration fabric are pivotal to its role in effectively minimizing the environmental impact of soil erosion.

What is the purpose of a silt fence?

A silt fence plays a crucial role in environmental protection, particularly within construction zones and regions vulnerable to soil erosion. Its primary function is to prevent sediment-laden water from exiting the site and infiltrating natural water bodies or stormwater systems, potentially causing pollution and adverse ecological consequences. Additionally, by capturing sediment and permitting water to filter through, silt fences are instrumental in maintaining water quality, preventing sediment accumulation in adjacent streams and rivers, and aiding in the effort to retain the soil on disturbed land. This dual capability supports the natural habitat, underscoring the silt fence’s significance in environmental conservation efforts.

How far into the ground should you dig the geotextile filter fabric for a silt fence?

The effectiveness of a geotextile silt fence largely depends on proper installation, which includes how deep the fabric is buried. Generally, the fabric should be trenched into the ground about 6 to 8 inches deep. This depth ensures that the bottom edge of the fabric is securely anchored, preventing water from undercutting the fence and allowing the system to capture sediment effectively. Proper trenching and backfilling are crucial to prevent erosion under the fence.

Does water drain through geotextile?

Yes, water can indeed drain through geotextile fabric, a fundamental property of silt fences underscored when a geotextile membrane is used, allowing water to pass through the membrane efficiently. The fabric’s permeability not only permits water to traverse but also traps soil particles, effectively mitigating sediment transport and soil erosion. This selective permeability plays a crucial role in harmonizing erosion control efforts with the need to prevent water buildup or flooding behind the fence, thus ensuring the protected area remains safe without negatively impacting water drainage capabilities.

Geotextile silt fences are a testament to the innovative use of technology for environmental protection. By understanding the material properties, purpose, installation requirements, and functional capabilities of these fences, we can appreciate their significance in construction and land management projects. Their ability to control sediment while allowing water flow highlights their role in sustainable development and environmental stewardship. As the construction industry and environmental regulators continue to seek effective erosion control solutions, the geotextile silt fence stands out as an essential tool in the quest to harmonize ecological preservation with human progress.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)