+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

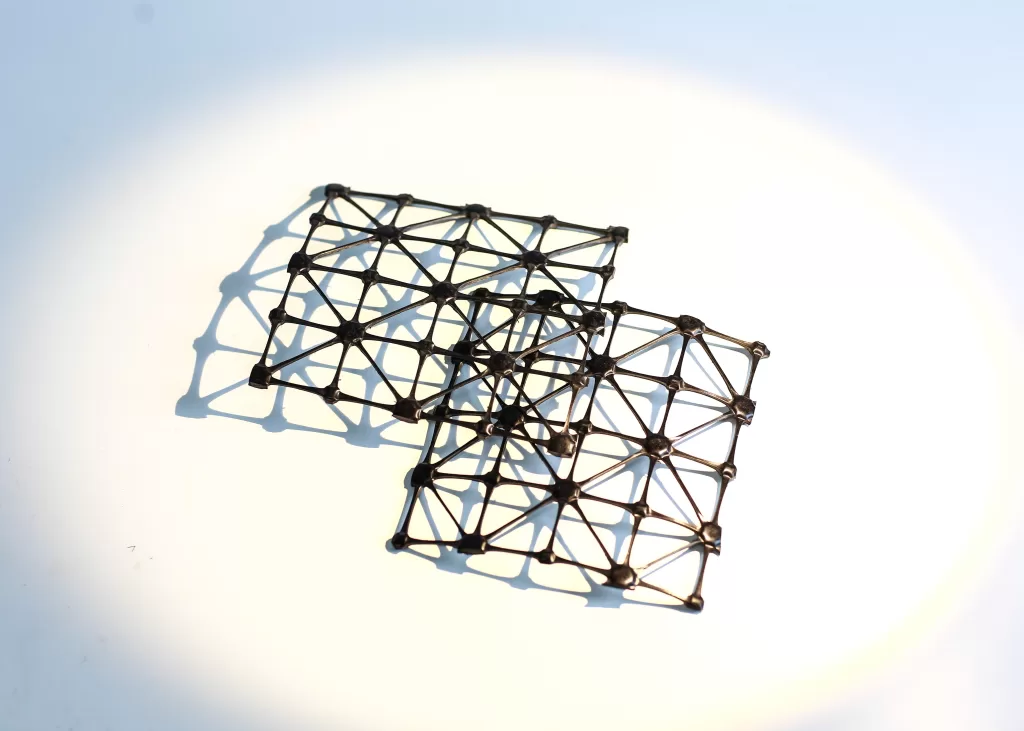

In the world of landscaping and outdoor construction, the materials chosen to lay the foundation of a project are critical to its longevity and effectiveness. Geogrid black polypropylene has emerged as a popular choice for reinforcing patio paver bases, offering durability, stability, and environmental resistance. This article delves into the properties of this material, how it’s used in patio construction, and the advantages it brings to both residential and commercial projects.

What is Geogrid Black Polypropylene?

Geogrid Black Polypropylene:

Composition:

- Material: Geogrid Black Polypropylene is made from high-quality polypropylene, a thermoplastic polymer known for its durability and resistance to various chemicals.

- Structure: It consists of a grid-like structure, where the strands are connected at their intersections, forming a network of apertures.

Purpose:

- Reinforcement: The primary purpose of Geogrid Black Polypropylene is to reinforce soil and other materials in construction projects.

- Stabilization: It stabilizes the ground by distributing loads over a larger area, reducing the stress on the underlying materials.

- Erosion Control: It helps in controlling erosion by providing a stable base that prevents soil displacement.

Applications:

- Road Construction: Used in the construction of roads and highways to improve the strength and longevity of the pavement by reinforcing the subgrade.

- Retaining Walls: Utilized in the construction of retaining walls to enhance their stability and load-bearing capacity.

- Landfills: Employed in landfill construction to reinforce the layers and prevent deformation.

- Railways: Used in railway construction to stabilize the tracks and reduce maintenance costs.

- Slope Protection: Applied in slope protection projects to prevent landslides and erosion by reinforcing the soil.

How does Geogrid Black Polypropylene enhance patio paver installations?

Improved Durability:

- Enhanced Load Distribution: Geogrid Black Polypropylene helps distribute loads evenly across the patio surface, reducing the stress on individual pavers and extending their lifespan.

- Resistance to Environmental Factors: This material is resistant to UV radiation, chemicals, and biological degradation, ensuring it remains effective over time.

Increased Stability:

- Prevents Paver Movement: By providing a stable base, Geogrid Black Polypropylene reduces the likelihood of paver displacement or shifting, maintaining a uniform and level surface.

- Soil Reinforcement: It reinforces the underlying soil, preventing erosion and subsidence that can lead to uneven surfaces and structural issues.

Enhanced Performance:

- Efficient Water Drainage: The geogrid structure allows for better water drainage, reducing the risk of water pooling and associated damage to the pavers and substrate.

- Improved Load-Bearing Capacity: The use of geogrid increases the load-bearing capacity of the patio, making it suitable for heavier loads without compromising structural integrity.

Cost-Effectiveness:

- Reduced Maintenance Costs: With improved durability and stability, the need for frequent maintenance and repairs is significantly reduced, saving time and money in the long run.

- Extended Lifespan: The enhanced performance and protection provided by Geogrid Black Polypropylene extend the overall lifespan of the patio installation.

Is Geogrid Black Polypropylene environmentally friendly?

Geogrids, including those made from black polypropylene, are often used in construction for soil stabilization, reinforcement, and erosion control. Assessing their environmental friendliness involves considering several factors:

Material Composition:

Polypropylene: This is a type of plastic derived from petrochemicals. While it is durable and resistant to many environmental factors, it is not biodegradable. Over time, polypropylene geogrids can break down into microplastics, which can have negative environmental impacts.

Manufacturing Process: The production of polypropylene involves the use of fossil fuels, contributing to carbon emissions. However, advancements in manufacturing processes aim to reduce the carbon footprint and increase efficiency.

Usage and Benefits:

- Soil Stabilization and Erosion Control: Geogrids help reduce soil erosion and improve the stability of slopes and embankments. This can lead to reduced land degradation and lower the risk of landslides, which have positive environmental benefits.

- Longevity: Polypropylene geogrids are durable and long-lasting, which means they need to be replaced less frequently compared to other materials. This can reduce the overall environmental impact in terms of production and transportation.

End-of-Life Considerations:

- Recyclability: Polypropylene can be recycled, though the recycling rates for construction materials can be lower than for other products. Proper disposal and recycling practices can mitigate some environmental concerns.

Alternative Materials:

- Biodegradable Geotextiles: There are alternatives to polypropylene geogrids, such as those made from natural fibers or biodegradable polymers. These alternatives may have a lower environmental impact but might not offer the same level of performance or durability.

Overall, while black polypropylene geogrids offer several benefits for soil stabilization and erosion control, their environmental friendliness is mixed due to their non-biodegradability and the carbon footprint associated with their production. Advances in recycling and the development of more sustainable materials could enhance their environmental profile.

What should be considered when installing Geogrid Black Polypropylene?

When installing Geogrid Black Polypropylene, several important factors should be considered to ensure proper performance and longevity of the material. Here are some key considerations:

Site Preparation

- Site Assessment: Evaluate the site conditions, including soil type, moisture content, and load requirements.

- Clearing and Grading: Remove vegetation, debris, and topsoil. Ensure the ground is level and compacted.

Geogrid Selection

- Type and Strength: Choose the appropriate type of geogrid based on the specific application (e.g., road construction, retaining walls, slope stabilization) and required strength.

- Compatibility: Ensure the geogrid is compatible with the soil and the type of fill material to be used.

Installation Procedures

- Cutting and Handling: Cut the geogrid to the required dimensions using appropriate tools. Handle the material carefully to avoid damage.

- Anchoring and Securing: Secure the geogrid in place using suitable anchors or pins to prevent movement during installation.

- Overlap and Joints: Overlap adjacent sections of geogrid by the manufacturer’s recommended amount, typically 0.3 to 0.5 meters (1 to 1.5 feet). Ensure joints are properly secured.

Placement of Fill Material

- Fill Material Quality: Use high-quality, well-graded fill material to ensure proper interlocking with the geogrid.

- Layering: Place fill material in layers, typically 0.2 to 0.3 meters (8 to 12 inches) thick. Compact each layer thoroughly before adding the next.

- Avoid Direct Contact: Ensure that construction equipment does not come into direct contact with the geogrid to prevent damage.

Compaction

- Compaction Equipment: Use appropriate compaction equipment to achieve the desired density. Light compaction equipment is recommended near the geogrid.

- Uniform Compaction: Ensure uniform compaction across the entire area to avoid uneven settlement.

Inspection and Quality Control

- Regular Inspections: Conduct regular inspections during and after installation to ensure proper placement and compaction.

- Documentation: Maintain detailed records of the installation process, including site conditions, materials used, and compaction results.

Environmental Considerations

- Weather Conditions: Avoid installation during adverse weather conditions, such as heavy rain, which can affect soil stability and compaction.

- Erosion Control: Implement erosion control measures to protect the geogrid and surrounding area during and after construction.

Safety Measures

- Protective Gear: Ensure that all personnel involved in the installation wear appropriate protective gear.

- Training: Provide adequate training to the installation team on proper handling and installation techniques.

By considering these factors, you can ensure the effective and durable installation of Geogrid Black Polypropylene, leading to improved soil reinforcement and stability in your project.

Geogrid black polypropylene offers a robust, eco-friendly solution for reinforcing patio paver bases. Its durability, ease of installation, and environmental benefits make it a favored choice among both DIY enthusiasts and professional landscapers. By understanding its properties and applications, homeowners can significantly enhance the longevity and stability of their patio projects, ensuring they enjoy their outdoor spaces for many years to come.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)