+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

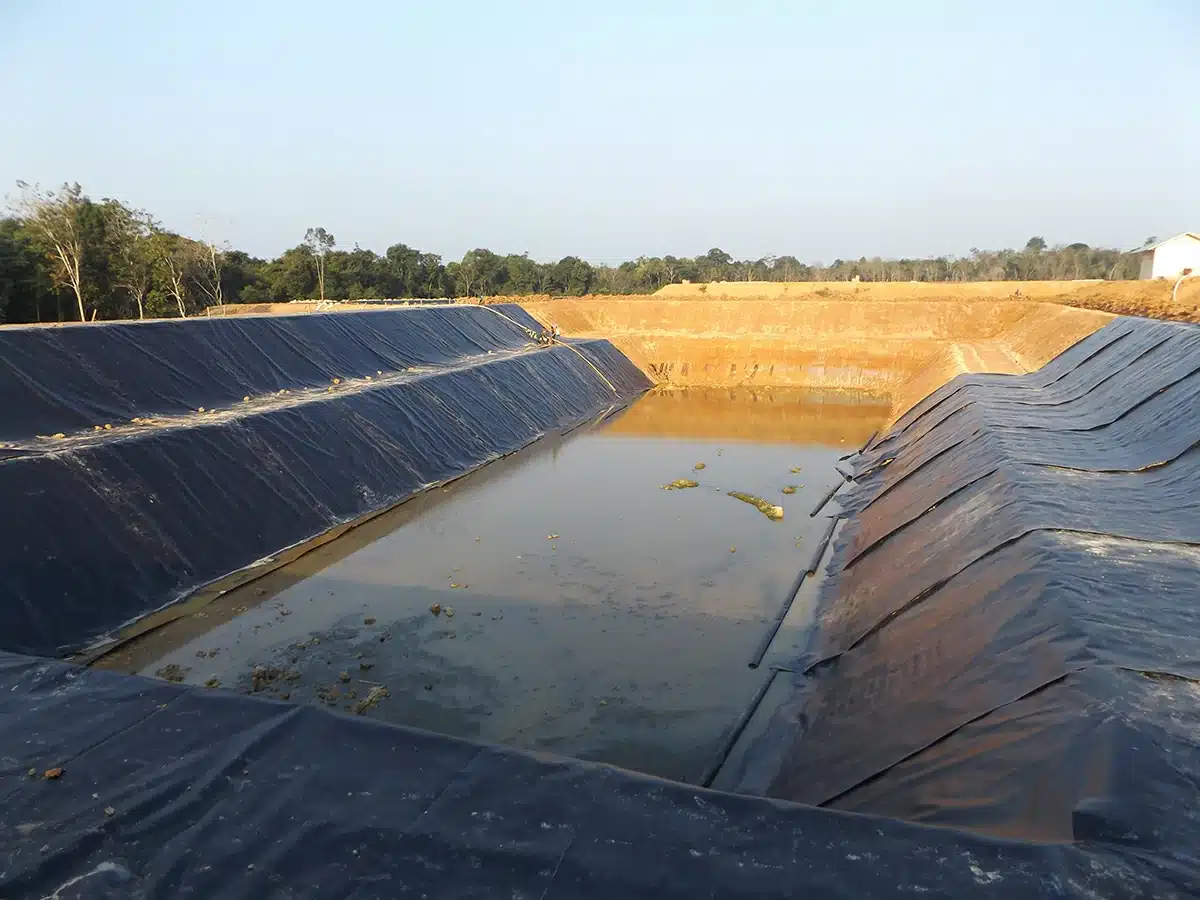

When it comes to the price of geomembranes, several factors can influence the overall cost. In this article, we’ll explore some common questions about geomembrane price and how these prices are determined in the geosynthetics industry.

What factors influence the geomembrane price?

The price of geomembranes depends on a variety of factors including material type, thickness, and manufacturing processes. High-quality materials like HDPE (High-Density Polyethylene) tend to be more expensive than lower-grade options due to their durability, resistance to chemicals, and UV stability. Additionally, the complexity of the manufacturing process, such as custom sizes or surface textures, can also affect pricing. Transportation costs and geographic location play a role as well, especially for large-scale projects or international orders.

How does the installation environment affect geomembrane price?

Installation conditions can significantly influence the total cost of geomembrane projects. For instance, installations in extreme environments (such as high temperatures or in areas with difficult terrain) may require more durable geomembranes, which can drive up the price. Special additives or coatings may be needed to enhance the geomembrane’s resistance to environmental factors, thereby adding to the cost. Moreover, the complexity of the installation process—whether it involves welding, seaming, or using additional protective layers—can increase both material and labor costs.

Are there cost-effective alternatives to geomembranes?

While geomembranes are highly effective for containment applications, there are cost-effective alternatives available for specific uses. For example, geotextiles or geosynthetic clay liners (GCLs) may be a more affordable option for projects with less stringent durability requirements. However, geomembranes are often chosen over these alternatives for their superior resistance to punctures, chemical exposure, and UV degradation. When considering alternatives, it’s crucial to evaluate the long-term benefits and performance needs of the project.

How can companies reduce the geomembrane price in large projects?

For large-scale projects, bulk purchasing and long-term contracts with suppliers can help reduce the overall geomembrane price. Companies can also minimize costs by standardizing product specifications and reducing the need for custom designs. Additionally, opting for standardized installation techniques and minimizing waste during installation can further lower expenses. Some companies may also provide discounts based on project size or repeat business, making it beneficial to establish long-term supplier relationships.

In conclusion, understanding the factors that influence geomembrane price is crucial for making informed decisions in geosynthetics projects. Whether you are looking to reduce costs or choose the best materials for your needs, being aware of these variables can help you navigate the pricing landscape more effectively.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)