+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

When considering a geomembrane liner for environmental protection, one of the most common questions asked is, “What is the geomembrane liner cost?” Geosynthetics are widely used in projects involving landfills, water containment, and environmental protection, but understanding the factors that influence pricing is crucial for making an informed decision. In this article, we’ll explore the important factors that affect the geomembrane liner cost and provide industry insights.

What factors affect the geomembrane liner cost?

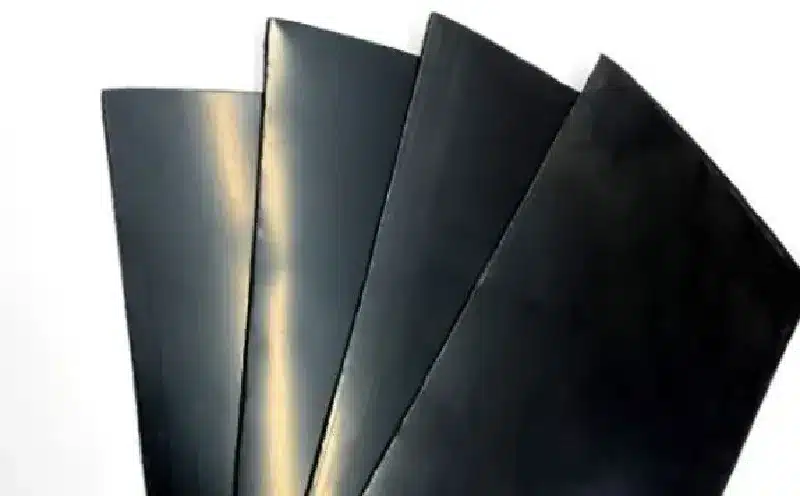

The geomembrane liner cost is influenced by several factors, including material type, thickness, and installation complexity. The most common materials used in geomembranes are High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), and Ethylene Propylene Diene Monomer (EPDM). Each material has its own price range based on its durability and resistance to chemical, environmental, and mechanical stress.

Factors Affecting Geomembrane Liner Cost:

- Installation Complexity – Irregular shapes or slopes raise costs.

- Material Type – HDPE is the cheapest; EPDM and RPP cost more.

- Thickness – Thicker liners are more expensive.

- Project Size – Bigger areas may reduce the cost per m².

- Surface Prep – Uneven ground may need extra work.

How does the project size impact the geomembrane liner cost?

The size of the project plays a critical role in determining the geomembrane liner cost. Larger projects, such as landfills or large-scale reservoirs, often benefit from economies of scale. Bulk purchasing, combined with the efficiency of larger-scale installations, can significantly reduce the cost per square foot.

Industry data shows that for large-scale projects, the cost can drop by 10-20% for geomembrane liners used in construction projects over 50,000 square feet (Geosynthetic Institute, 2023). For smaller, more specialized applications, such as pond linings or waterproofing in residential areas, the cost tends to be higher per square foot.

What are the maintenance costs associated with geomembrane liners?

While the geomembrane liner cost primarily focuses on the initial installation, it’s important to factor in long-term maintenance costs. Geomembrane liners typically require less maintenance than other containment materials. However, they should be inspected regularly for punctures, tears, or other damage that could compromise their integrity.

Industry data indicates that the lifespan of a high-quality HDPE liner can be between 20-30 years with minimal maintenance, while PVC and EPDM liners can last 15-25 years (Geosynthetic Institute, 2023). The cost of repairs or replacements is typically lower for HDPE, making it a popular choice for long-term projects.

How can installation methods affect the geomembrane liner cost?

The geomembrane liner cost can also vary depending on the installation method chosen. Liner installations can be done through welding, adhesive bonding, or mechanical fastening. While welding is the most common and secure method, it may require specialized equipment and skilled labor, which can add to the overall project cost.

Industry data shows that welded installations, which require high-precision machinery, can increase the installation cost by 15-25% compared to simpler adhesive bonding or fastening methods (Geosynthetic Institute, 2023). However, welded liners often provide better durability and fewer long-term maintenance issues, making them a cost-effective option in the long run.

Understanding the geomembrane liner cost is crucial for both project planning and budgeting. By considering factors such as material choice, project size, maintenance needs, and installation methods, businesses and contractors can make informed decisions that balance both upfront and long-term costs. Always consult with experts in geosynthetics to get precise pricing based on your project’s specific requirements and to ensure the best solution for your needs.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)