+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Biaxial Plastic Geogrid has gained prominence in the field of civil engineering and construction due to its unique properties and versatility. In this article, we will delve into the concept of biaxial geogrid, its differences from uniaxial geogrid, the significance of plastic geogrid, and the distinctions between uniaxial and biaxial load. By the end, you’ll have a comprehensive understanding of how this innovative material is transforming construction practices.

What is Biaxial Geogrid?

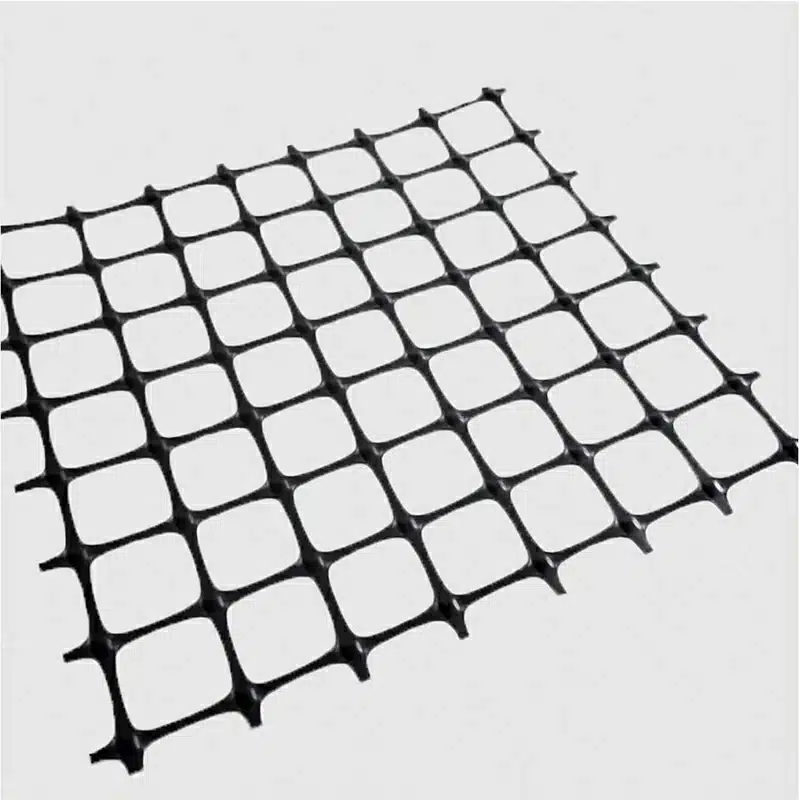

Biaxial geogrids are a type of geosynthetic material crafted from high-density polyethylene (HDPE) or other plastics. They boast a grid-like structure with evenly spaced openings in both the longitudinal and transverse directions. This special design grants them remarkable tensile strength in both directions, making them perfect for bolstering soil in applications like road construction, retaining walls, embankments, and erosion control projects.

What is the Difference Between Uniaxial and Biaxial Geogrid?

The primary difference between uniaxial and biaxial geogrid lies in their tensile strength characteristics. Uniaxial geogrids offer strength in only one direction, typically the longitudinal direction, making them suitable for applications where reinforcement is needed in a single direction, such as under roads or foundations. On the other hand, biaxial geogrids, as the name suggests, provide tensile strength in both the longitudinal and transverse directions, allowing for even distribution of loads and reinforcement in multiple dimensions. This versatility makes biaxial geogrids more suitable for a wider range of construction projects.

What is Plastic Geogrid?

Plastic geogrid, such as biaxial plastic geogrid, is made from high-density polyethylene (HDPE), a polymer plastic. Its purpose is to improve the mechanical properties of soil, enhancing its stability and load-bearing capacity. These geogrids are employed in civil engineering projects like roads, embankments, slopes, and landfills to reinforce and stabilize the soil. They achieve this by spreading applied loads over a larger area, thereby reducing soil stress and preventing settlement or deformation.

What is the Difference Between Uniaxial and Biaxial Load?

In engineering, uniaxial and biaxial loads are about the direction in which forces or stresses are applied. When forces apply in only one direction, whether horizontally or vertically, it’s called a uniaxial load. This occurs when stress primarily concentrates in one direction, like the weight of a building on its foundation. On the other hand, biaxial loads involve forces applied in two perpendicular directions simultaneously, resulting in a more complex load distribution pattern. To illustrate, think of it this way: a column is a uniaxial column if the combined effect of load and configuration of the column is symmetric; a biaxial column, if the combined effect is unsymmetric or eccentric. Biaxial plastic geogrids shine in applications where the load spreads in multiple directions, ensuring top-notch stability and reinforcement.

In conclusion, Biaxial Plastic Geogrid is a remarkable geosynthetic material that has revolutionized modern construction. Its ability to provide strength in both longitudinal and transverse directions sets it apart from uniaxial geogrids, making it a versatile choice for a wide range of civil engineering projects. By understanding the principles behind plastic geogrids and the difference between uniaxial and biaxial loads, engineers and construction professionals can harness the full potential of this innovative material to enhance the durability and longevity of their projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)