+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

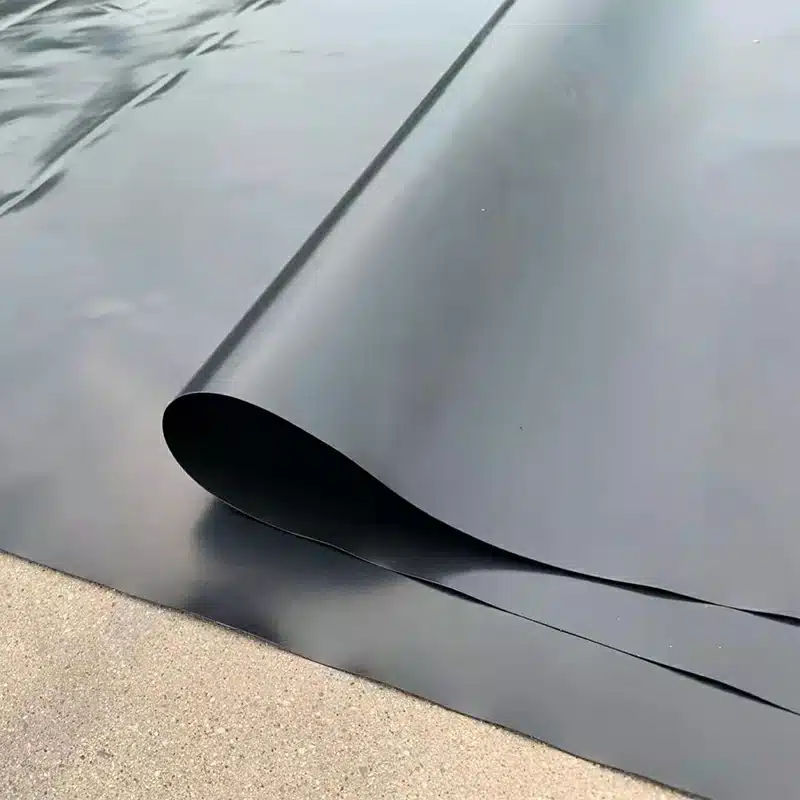

HDPE geomembrane liners have become essential materials in modern engineering projects that require effective containment and environmental protection. Known for their strength, chemical resistance, and impermeability, these liners serve as reliable barriers to prevent leakage and contamination in applications ranging from landfills to water reservoirs and mining operations. Understanding what HDPE geomembrane liners are, how they work, and where they are best applied is crucial for engineers, contractors, and environmental managers aiming to ensure long-lasting, safe, and cost-effective solutions.

What is geomembrane lining?

Geomembrane lining refers to the use of a very thin, impermeable membrane made of synthetic material to provide a barrier to the movement of water, fluids, or other substances. This type of lining is used in various environmental, geotechnical, and hydraulic applications to control and contain the movement of liquids or gases. The primary purpose of a geomembrane liner is to prevent contamination of the soil and groundwater or, conversely, to protect stored liquids from being contaminated by the underlying ground.

Key aspects of geomembrane lining include:

- Material Composition: Geomembranes are made from various polymers, including High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Polyvinyl Chloride (PVC), Ethylene Propylene Diene Monomer (EPDM), and others. The choice of material depends on the specific requirements of the project, such as chemical resistance, flexibility, and durability.

- Applications: Geomembrane liners are used in a wide range of applications. Common uses include lining for landfills to prevent leachate from contaminating groundwater, lining for ponds, lakes, and reservoirs to prevent water loss, lining for mining operations (such as heap leach pads), and in secondary containment systems for preventing spills from contaminating soil and water.

- Installation: The installation of geomembrane liners is a specialized task. It involves site preparation, deploying the geomembrane panels, and then seaming them together to form a continuous barrier. The quality of installation, including seam integrity, is critical to the liner’s effectiveness.

What is the purpose of a geomembrane?

The primary purpose of a geomembrane is to act as a barrier to prevent the migration of liquids, gases, or contaminants. This impermeable layer is used in various applications to protect the environment, manage resources, and ensure safety in industrial and construction projects. The specific purposes of geomembranes include:

- Containment of Contaminants: In waste disposal facilities, like landfills, geomembranes prevent hazardous leachate – the liquid that percolates through waste material – from contaminating the soil and groundwater.

- Water Retention: In ponds, reservoirs, and irrigation systems, geomembranes are used to prevent water loss due to seepage into the ground. This is crucial for water conservation in agriculture, aquaculture, and recreational water bodies.

- Environmental Protection: Geomembranes are used in environmental protection projects, such as the capping of contaminated sites to prevent the spread of pollutants, or in remediation projects where they prevent contaminants from entering or exiting a designated area.

- Chemical Containment: In industrial applications, geomembranes are used to line tanks or containment areas where chemicals are stored or processed, preventing any potential leaks or spills from seeping into the ground.

- Mining Applications: In the mining industry, geomembranes are used in heap leach pads, where they contain the leaching solution and collect the leachate for processing to extract minerals from mined materials.

What are the main applications and benefits of HDPE geomembrane liners?

HDPE geomembrane liners are highly versatile and widely used across many industries due to their excellent durability, chemical resistance, and impermeability. Their primary applications and benefits include:

- Landfill Liners and Caps: HDPE liners are used extensively to line landfill bases and caps, effectively containing leachate and preventing harmful contaminants from infiltrating soil and groundwater. Their chemical resistance ensures long-term environmental protection.

- Water Containment: These liners are ideal for lining reservoirs, ponds, irrigation canals, and water treatment facilities. They prevent water loss through seepage, helping conserve water resources and improve irrigation efficiency in agriculture.

- Mining Operations: In mining, HDPE geomembranes serve as liners for heap leach pads and tailings ponds, containing toxic by-products and preventing contamination of surrounding soils and waterways. Their robustness withstands harsh mining conditions.

- Secondary Containment: Industrial sites storing hazardous chemicals or petroleum products use HDPE liners for secondary containment systems, providing a fail-safe barrier to capture leaks or spills, minimizing environmental damage.

Benefits include:

- Exceptional chemical and UV resistance for long-term durability.

- High tensile strength and puncture resistance, suitable for demanding environments.

- Flexibility and ease of installation, reducing labor and project time.

- Cost-effective solution by minimizing maintenance and extending service life.

Understanding these applications helps engineers and project managers select the right liner system to meet environmental safety, regulatory compliance, and project performance goals.

What is a geomembrane liner for a landfill?

- A geomembrane liner is a synthetic impermeable barrier used in landfills to contain waste and prevent leachate—the liquid that drains from waste—from contaminating soil and groundwater.

- These liners are typically made from materials such as High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), or Polyvinyl Chloride (PVC), chosen based on site-specific requirements.

- The primary function is to act as a containment layer, blocking harmful chemicals, heavy metals, and pathogens from escaping into the environment.

- Geomembrane liners are often combined with other layers, like compacted clay or geotextiles, to form a multilayer protective system.

- Installation includes preparing a smooth landfill base, carefully unrolling and positioning the liner, welding seams to create a continuous barrier, and thorough inspection to ensure no leaks.

- Challenges include risks of puncture from debris, deformation from ground movement, and degradation due to UV exposure, all requiring proper quality control and maintenance.

- Their use is governed by strict environmental regulations (e.g., EPA’s RCRA standards) that specify thickness, chemical resistance, and installation criteria to ensure long-term containment and environmental safety.

What is the difference between geotextile and geomembrane?

Geotextiles, just as its name implies, are made of nonwoven fabrics and are mainly used to consolidate subsoil. Geomembrane is made of high-density polyethylene, primarily for seepage-proofing.

When it comes to safeguarding the environment and managing containment solutions, a geomembrane liner stands out as a crucial component. Geomembrane liners are engineered to provide impermeable barriers, preventing the seepage of liquids or contaminants into the ground. These versatile liners find application in a wide range of industries, from agriculture and construction to wastewater management and mining. Whether you’re looking to line a pond, landfill, or industrial reservoir, understanding the benefits and types of available can make a significant difference in your project’s success and environmental stewardship efforts.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)