+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the realm of environmental engineering and construction, selecting the right materials is pivotal for the success and durability of projects. One such material, LLDPE resin, has become increasingly popular for its role in producing geomembranes. These geomembranes serve as critical components in various applications, from water reservoirs to hazardous waste containment. This article delves into the essentials of LLDPE resin for geomembranes, exploring its uses, benefits, and how it compares to other materials in the field.

What is LLDPE resin used for?

LLDPE (Linear Low-Density Polyethylene) resin is a versatile material used in a wide range of applications due to its flexibility, durability, and resistance to chemicals. Some of the common uses include:

- Packaging: It’s widely used in the production of plastic films for packaging materials, such as stretch wrap, grocery bags, and bubble wrap. LLDPE is valued for its ability to stretch and resist puncturing.

- Pipes: LLDPE is used in the manufacturing of pipes for water and gas distribution systems, as well as for irrigation, thanks to its strength and flexibility.

- Plastic Products: LLDPE is used in making toys, containers, and lids because of its tough yet flexible nature.

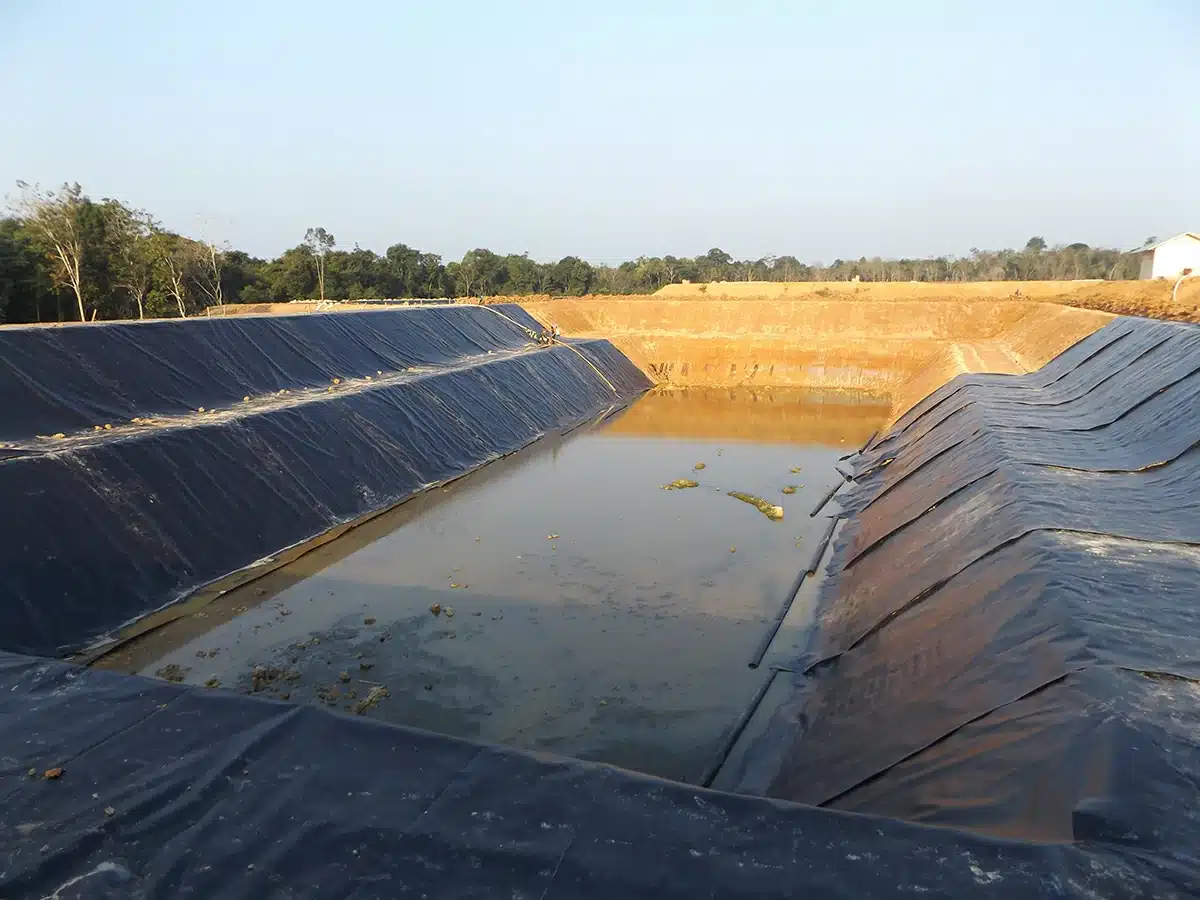

- Geosynthetics: It is also used in the production of geosynthetic materials like geomembranes for environmental protection, landfill liners, and pond liners due to its excellent impermeability.

- Agriculture: It is used in agricultural films to cover greenhouses or fields, providing UV resistance and durability under varying weather conditions.

- Cables: LLDPE is often used as an insulation material in electrical and communication cables due to its low moisture absorption and high dielectric strength.

What is the difference between HDPE and LLDPE geomembrane?

The key differences between HDPE (High-Density Polyethylene) and LLDPE (Linear Low-Density Polyethylene) geomembranes come down to their molecular structure, which affects their mechanical properties, flexibility, puncture resistance, and application suitability.

Here’s a quick comparison:

| Property | HDPE Geomembrane | LLDPE Geomembrane |

|---|---|---|

| Flexibility | Less flexible; more rigid | More flexible and elastic |

| Tensile Strength | Higher | Slightly lower |

| Puncture Resistance | Moderate | Higher due to better elongation |

| Elongation at Break | Lower (about 10–20%) | Higher (about 600–800%) |

| Stress Crack Resistance | Lower | Higher |

| Welding/Seaming | More sensitive to seaming parameters | Easier and more forgiving to weld |

| UV Resistance | Excellent | Good (but generally less than HDPE) |

| Cost | Usually more cost-effective | Slightly more expensive |

| Common Uses | Landfills, mining, water containment | Ponds, canals, temporary liners, flexible containment |

| Thickness Range | Typically thicker | Can be thinner due to flexibility |

Which is better: HDPE or LLDPE?

The choice between HDPE and LLDPE geomembranes depends on the specific requirements of the project. While HDPE is better suited for scenarios demanding high mechanical strength and puncture resistance, often used in applications where the geomembrane is exposed and must withstand environmental stressors, LLDPE is recognized as superior when compared to both LDPE and HDPE due to its excellent flexibility and stretch. This makes LLDPE preferable in situations requiring the geomembrane to fit tightly over irregular shapes and surfaces, showcasing its adaptability and resilience. Therefore, the “better” material is the one that aligns with the project’s needs, whether it be the rigidity and strength of HDPE or the enhanced flexibility and performance advantages of LLDPE.

How do you seal a geomembrane?

Sealing a geomembrane is crucial to ensure its effectiveness as a barrier. The process involves welding the edges of the geomembrane sheets together to form a continuous barrier. For LLDPE geomembranes, this is typically done using thermal welding, a method that applies heat to melt the geomembrane material at the seams, fusing them together upon cooling. Additionally, enhancing the seal with a neoprene gasket and a stainless steel clamp sealed on the edge of the geomembrane with a General Electric Sealer, RTV 103, or equivalent can further secure the integrity of the barrier. Properly welded seams, along with these additional sealing measures, are critical to prevent leaks and ensure the longevity of the geomembrane installation. Professionals often employ testing methods, such as air pressure tests or vacuum tests, to verify the integrity of the seams.

LLDPE resin stands out in the construction and environmental protection industries for its role in producing high-quality geomembranes. With its exceptional flexibility, chemical resistance, and durability, LLDPE geomembranes offer a reliable solution for a wide range of containment needs. The choice between LLDPE and HDPE geomembranes ultimately depends on the project’s specific requirements, with each material offering distinct advantages. Proper installation and sealing techniques are essential to maximize the effectiveness of these geomembranes, ensuring they meet the intended performance standards. As the demand for sustainable and durable construction materials grows, LLDPE resin for geomembranes will continue to play a pivotal role in environmental protection projects worldwide.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)