+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the realm of civil engineering and construction, the quest for materials that offer both durability and efficiency has led to innovative solutions. Among these, fiberglass geogrids stand out as a pivotal element in reinforcing soil and enhancing the longevity of paved and unpaved surfaces. This article delves into the science behind fiberglass geogrids, explaining their significance, benefits, applications, and impact on future construction projects.

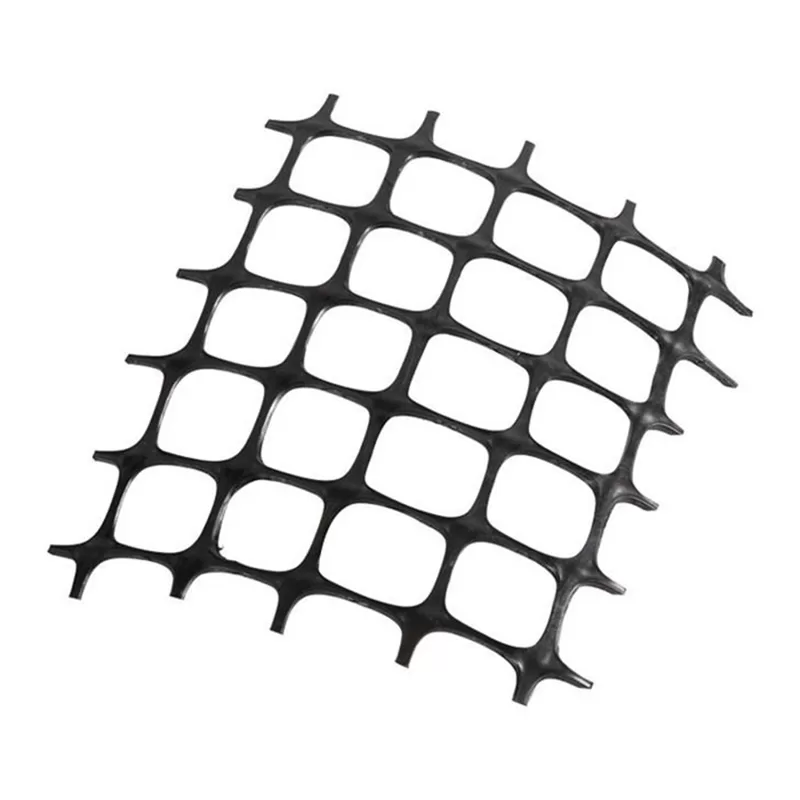

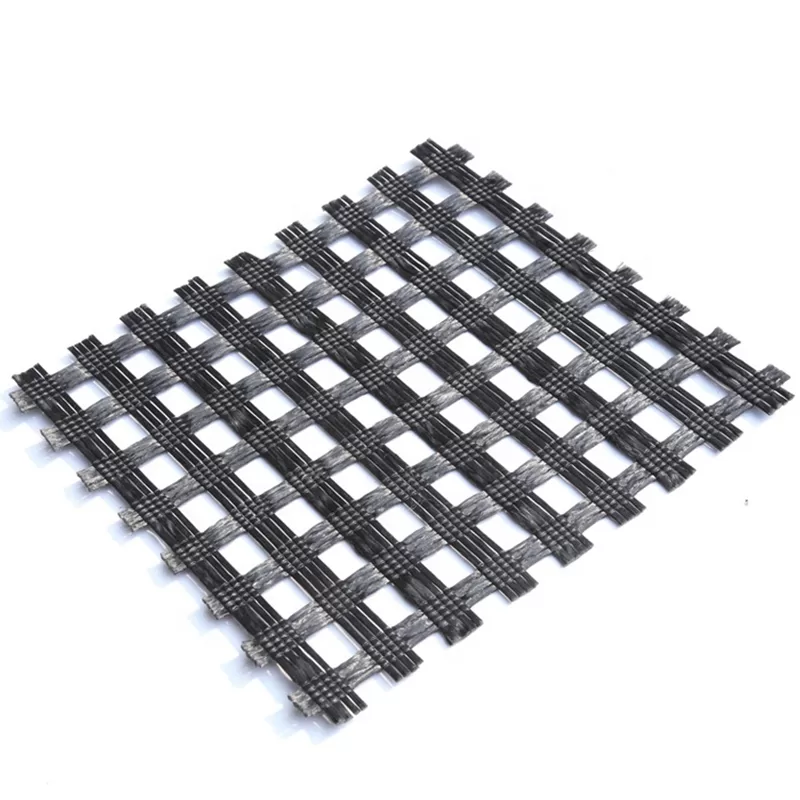

What is Fiberglass Geogrid and How Does it Work?

Fiberglass geogrid is a geosynthetic reinforcement material made from fiberglass filaments coated with a polymer, usually PVC, to enhance durability and chemical resistance. It is commonly used in road construction and asphalt reinforcement. Its main functions include:

- Tensile reinforcement – the grid has high tensile strength and resists stretching, which helps control deformation in weak soils or pavement layers;

- Load distribution – it spreads loads over a wider area, reducing pressure on the base and subgrade;

- Crack control – in asphalt overlays, it prevents reflective cracking by absorbing stress at joints or existing cracks; and

- Extended service life – by improving structural integrity, it extends pavement lifespan and lowers maintenance costs. Fiberglass geogrids are widely applied in highways, airport runways, parking lots, and industrial yards due to their high strength, low elongation, chemical resistance, and easy installation.

What Are the Main Benefits of Using Fiberglass Geogrids in Construction?

- Enhanced Durability: They significantly increase the lifespan of roads and pavements by preventing common issues like cracking and potholing.

- Cost Efficiency: By extending the service life of infrastructure, they reduce the need for frequent repairs, translating into long-term savings.

- Environmental Sustainability: Fiberglass geogrids can reduce the thickness of pavement layers, meaning less raw material is needed, which minimizes the environmental footprint.

- Versatility: Suitable for a wide range of applications including roads, railways, airports, and parking lots, making them a flexible choice for various projects.

Where Are Fiberglass Geogrids Most Effectively Used?

- Road Construction: Improving the performance of both asphalt and concrete pavements by reinforcing the base layer.

- Slope Stabilization: Preventing soil erosion and landslides on embankments and slopes.

- Railway Tracks: Stabilizing the railway ballast, ensuring smoother and safer train operations.

- Airport Runways and Parking Lots: Enhancing the capacity to withstand heavy aircraft and vehicular traffic.

What is the Future of Fiberglass Geogrids in Construction?

The future of fiberglass geogrids in construction looks promising, driven by continuous advancements in material science and construction technology. Innovations are likely to produce even more durable and environmentally friendly geogrids. Furthermore, as the global focus shifts towards sustainable and resilient infrastructure, the demand for materials that contribute to these goals is set to increase, positioning fiberglass geogrids as a key player in the future of construction.

Fiberglass geogrids are a cornerstone in modern construction, offering unmatched durability, cost efficiency, and versatility. By understanding their role and benefits, stakeholders in the construction industry can make informed decisions, paving the way for infrastructure that stands the test of time. As we continue to innovate and seek sustainable solutions, fiberglass geogrids will undoubtedly play a crucial role in shaping the future of our built environment.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)