+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

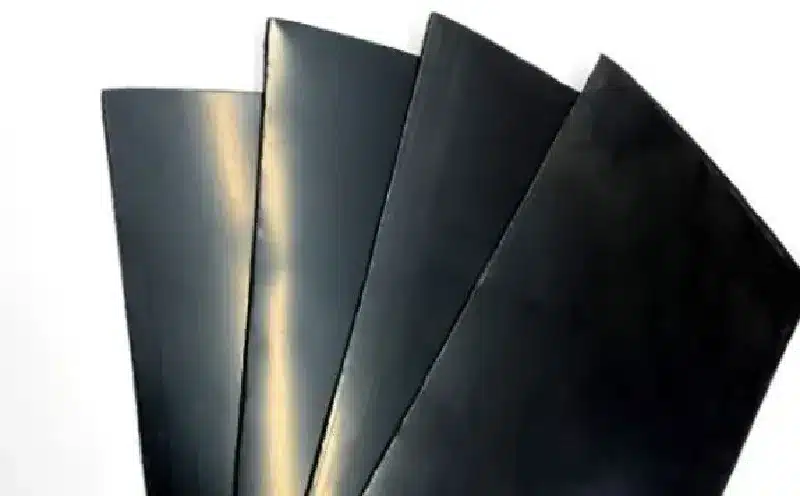

In the world of aquatic leisure and construction, the quest for durable, efficient, and eco-friendly materials is never-ending. The introduction of High-Density Polyethylene (HDPE) geomembrane as a pool liner material has set a new standard in the industry. Unlike traditional materials, HDPE offers unparalleled benefits in terms of longevity, environmental resistance, and maintenance. This article delves into the specifics of HDPE geomembrane pool liners, exploring their thickness, material properties, differences from PVC geomembranes, and overall purposes, providing a comprehensive understanding of why they are becoming the go-to choice for pool construction and renovation projects.

How thick is an HDPE geomembrane liner?

- Water containment and leak prevention: HDPE geomembranes provide a highly impermeable barrier that effectively prevents water loss and maintains stable water levels in swimming pools, decorative ponds, and reservoirs.

- Chemical resistance: HDPE exhibits excellent resistance to chlorine, disinfectants, salts, and common water treatment chemicals, significantly reducing material degradation and extending liner service life.

- Structural protection: By isolating concrete, soil, and subgrade materials from constant water exposure, HDPE liners help minimize cracking, erosion, and chemical attack on pool and containment structures.

- UV and weather durability: HDPE liners are engineered to withstand prolonged UV exposure and wide temperature fluctuations, making them suitable for long-term use in both indoor and outdoor environments.

- Hygiene and water quality control: The smooth, non-porous surface limits algae growth and bacterial penetration, simplifying cleaning procedures and reducing ongoing maintenance requirements.

- Environmental safety: HDPE is non-toxic, chemically stable, and environmentally safe, allowing its use in recreational water facilities, aquaculture systems, and potable water containment when properly specified.

Overall, HDPE lining delivers long-term performance, lower maintenance costs, and high reliability for pool and water containment applications, making it a superior choice for modern construction and renovation projects.

What is HDPE geomembrane material?

High-Density Polyethylene (HDPE) geomembrane is a type of plastic liner used in various civil engineering and environmental applications. It is made from high-density polyethylene resin, a thermoplastic polymer known for its strong molecular structure and resistance to chemicals, punctures, and environmental stressors.

HDPE geomembranes are typically manufactured through a process called extrusion, where the polymer is melted and formed into a continuous sheet of varying thicknesses and widths. These sheets can then be welded together on-site to create large liners for containment applications.

HDPE geomembranes are commonly used in:

| Landfills | They serve as liners or caps to prevent the leachate from contaminating surrounding soil and groundwater. |

| Mining | HDPE geomembranes are used in tailings dams and heap leach pads to contain and manage mine waste and chemicals. |

| Water and wastewater containment | They are used in reservoirs, ponds, canals, and wastewater treatment facilities to prevent seepage and leakage. |

| Environmental protection | HDPE geomembranes are utilized in applications such as secondary containment systems for industrial facilities, agricultural ponds, and erosion control. |

| Aquaculture | They are employed in fish ponds and shrimp farming to prevent water seepage and maintain water quality. |

HDPE geomembranes offer several advantages, including high tensile strength, flexibility, chemical resistance, UV resistance, and ease of installation. These characteristics make them suitable for a wide range of applications where impermeable barriers are necessary to contain liquids, gases, or solids.

What is the difference between PVC and HDPE geomembrane?

PVC and HDPE geomembranes differ in flexibility, chemical resistance, durability, and applications. PVC is more flexible and easier to install, making it suitable for water containment and non-hazardous waste. However, it has lower chemical resistance and can degrade under UV exposure. HDPE, while less flexible, offers superior chemical resistance, UV stability, and durability, making it ideal for landfills and hazardous waste containment. HDPE also has a longer lifespan but comes at a higher initial cost. PVC is generally more cost-effective but less suitable for harsh environments.

What Is the Purpose of HDPE Lining in Pool and Water Containment Applications?

The primary purpose of HDPE lining is to act as a high-performance impermeable barrier that prevents water loss, protects underlying structures, and ensures long-term durability in pools and other water containment systems.

In pool and aquatic applications, HDPE lining serves several key functions:

- Water containment and leak prevention: HDPE geomembranes are virtually impermeable, preventing seepage and maintaining consistent water levels in swimming pools, decorative ponds, and reservoirs.

- Chemical resistance: HDPE resists chlorine, disinfectants, salts, and water treatment chemicals commonly used in pools, reducing material degradation and liner failure over time.

- Structural protection: The liner isolates concrete, soil, or subgrade materials from continuous water exposure, minimizing cracking, erosion, and chemical attack on the pool structure.

- UV and weather durability: HDPE liners withstand prolonged sunlight exposure and temperature fluctuations, making them suitable for both indoor and outdoor pools with extended service life.

- Hygiene and water quality control: The smooth, non-porous surface inhibits algae growth and bacterial penetration, simplifying cleaning and reducing maintenance requirements.

- Environmental safety: HDPE is non-toxic and environmentally stable, allowing safe use in recreational water features, aquaculture, and potable water containment when properly specified.

Overall, HDPE lining ensures long-term performance, reduced maintenance costs, and enhanced reliability for pools and water containment systems. Its combination of impermeability, chemical resistance, and durability makes it a superior solution for modern pool construction and renovation projects.

HDPE geomembrane pool liners represent a significant advancement in pool construction and maintenance technology. With their exceptional thickness, material properties, and durability compared to traditional materials like PVC, HDPE liners offer a cost-effective, long-term solution for creating and preserving water features. Their ability to withstand environmental challenges, along with ease of installation, makes them a superior choice for both residential and commercial applications. As the industry continues to evolve, HDPE geomembranes are set to play a pivotal role in shaping the future of aquatic leisure spaces.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)