+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

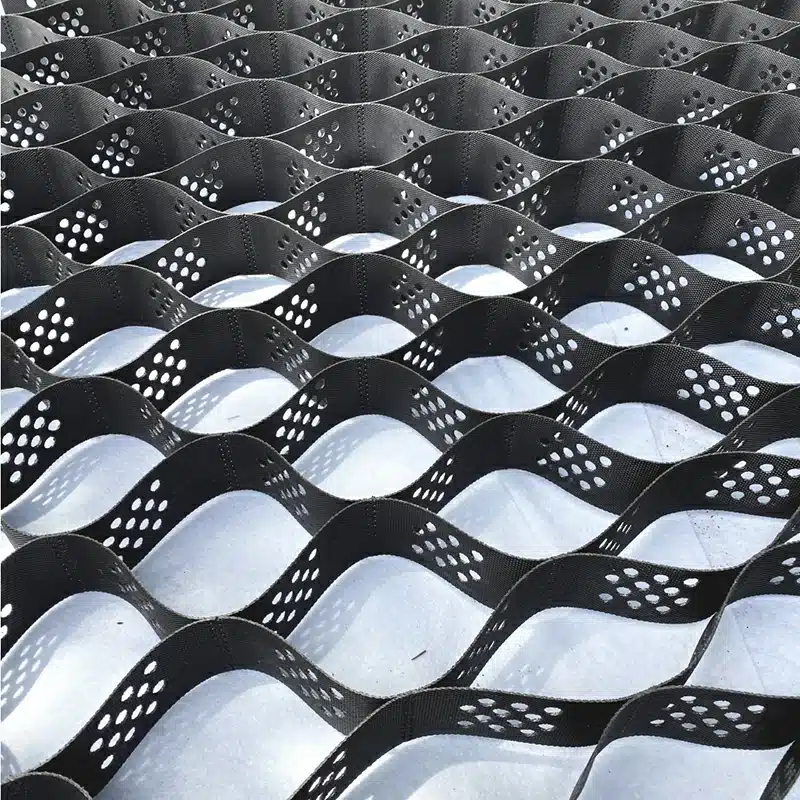

In the world of civil engineering and geotechnical projects, ensuring slope stability is of paramount importance. Geocells have emerged as a revolutionary solution for stabilizing slopes and preventing erosion.

What is a Geocell and How Does it Work for Slope Stability?

Los geocells son estructuras tridimensionales en forma de panal, fabricadas con polímeros de alta resistencia, utilizadas para reforzar suelos y prevenir la erosión. Su funcionamiento principal se basa en:

- Confinamiento del suelo: las celdas mantienen la tierra en su lugar, evitando desplazamientos y mejorando la cohesión;

- Distribución de cargas: reparten de manera uniforme las cargas sobre la superficie del talud, aumentando su estabilidad;

- Control de la erosión: reducen la pérdida de suelo por escorrentía y protegen contra la erosión superficial;

- Mejora del drenaje: permiten el paso del agua, evitando acumulaciones que puedan generar presión hidráulica;

- Versatilidad en aplicaciones: se usan en carreteras, control de erosión costera, gestión de desechos mineros y otros proyectos geotécnicos.

Gracias a estas características, los geocells proporcionan una solución confiable, sostenible y duradera para mantener la integridad de los taludes y minimizar el impacto ambiental.

What Are the Advantages of Using Geocells for Slope Stabilization?

Geocells are great for slope stabilization because they:

- Increase Soil Strength: They prevent soil movement and improve shear strength.

- Control Erosion: Their structure reduces soil displacement and erosion.

- Improve Drainage: They allow water flow, preventing pressure buildup.

- Cost-Effective: Cheaper and easier to install than traditional methods.

- Long-Lasting: Made from durable materials, ensuring lasting stability.

- Environmentally Friendly: Use local materials and promote vegetation growth.

In short, geocells provide a reliable, affordable, and sustainable solution for stabilizing slopes.

How Do I Determine the Right Geocell Specifications for My Project?

For the right geocell specifications:

- Define the project requirements and load-bearing needs.

- Assess the soil type and site conditions.

- Choose the appropriate material based on environmental factors.

- Select the right cell height and size for your application.

- Ensure the geocell’s strength matches the expected load.

If you have more specific project details, I can help refine these recommendations further!

What Maintenance Is Required for Geocell-Supported Slopes?

Maintaining a geocell-supported slope is essential to ensure long-term stability and performance. Key steps include:

- Regular inspections: Check for damage, wear, or deformation in the geocell material, and monitor soil displacement within the cells.

- Vegetation monitoring: If plants are used for slope stabilization, ensure they are healthy and well-established, as roots help secure the soil.

- Drainage checks: Inspect drainage channels and outlets for blockages, and address any water pooling that could cause erosion or stress on the slope.

- Structural integrity: Examine anchors, stakes, and geocell connections to ensure the system remains firmly in place.

- Load monitoring: For slopes exposed to vehicular or heavy loads, verify that load distribution remains within design limits.

- Repairs and replacement: Fix minor tears or deformations on-site, and replace severely damaged sections according to manufacturer guidelines.

- Documentation and professional assessment: Keep records of inspections and maintenance, and consider periodic evaluations by geotechnical engineers for critical or complex slopes.

Proper maintenance ensures geocell-supported slopes remain safe, effective, and long-lasting, maximizing their environmental and structural benefits.

Optimizing slope stability with geocells is an intelligent choice for engineers and project managers looking to enhance infrastructure while minimizing environmental impact. By understanding the benefits, specifications, and maintenance requirements of geocell-supported slopes, you can make informed decisions to ensure the success of your project.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)