+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

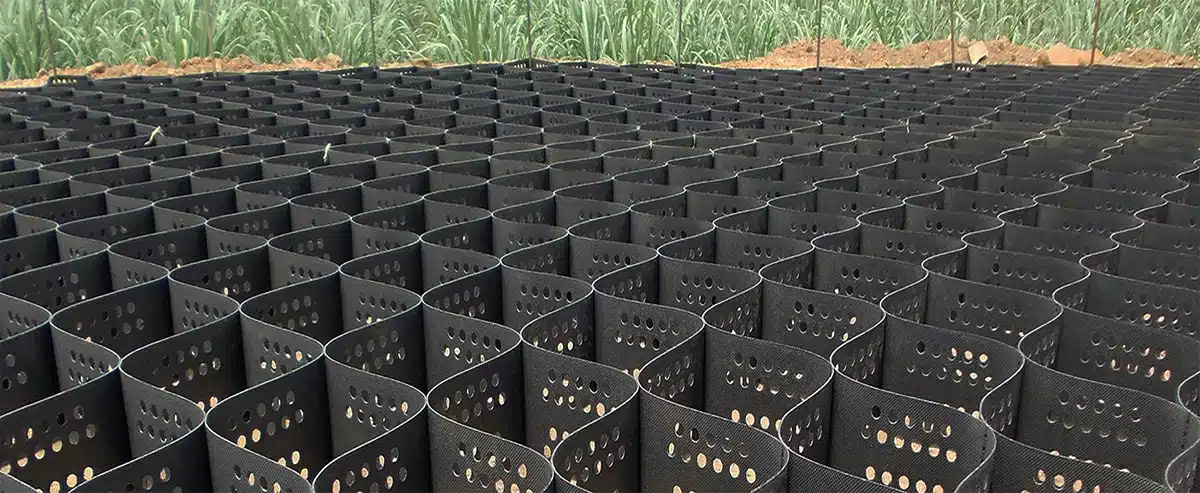

In the realm of civil engineering and construction, soil stabilization is a critical concern, directly impacting the longevity and safety of infrastructure projects. Among the myriad of solutions available, Geocell technology stands out, particularly the variant known as “Geocell .” This article delves into the essence of Geocell , exploring its manufacturing process, applications, and benefits, aiming to shed light on its significance in modern construction practices.

What is Geocell?

Geocell is a type of cellular confinement system made from high-density polyethylene or other polymer materials. It’s a three-dimensional honeycomb-like structure used in civil engineering and construction projects to improve ground stability. Here’s how it functions and some common applications:

- Purpose: The primary purpose of Geocell is to reinforce and stabilize soil, preventing erosion and enhancing load distribution across various surfaces.

- Functionality: The cells are filled with soil, gravel, sand, or other granular materials. Once filled, the interconnected cells create a stable and uniform surface that provides lateral confinement, reducing movement of the infill and enhancing overall strength.

Applications:

- Slope Protection: Prevents soil erosion on steep slopes and embankments.

- Load Support: Distributes loads more evenly for unpaved roads, parking lots, and temporary construction access roads.

- Retaining Walls: Used to build reinforced retaining walls for increased soil retention.

- Channel Protection: Reduces erosion in channels, ditches, and rivers.

- Green Infrastructure: Offers solutions for landscaping and sustainable urban drainage.

How does Geocell contribute to soil stabilization?

Geocell technology, which consists of three-dimensional, honeycomb-like structures made from polymer materials, enhances soil stability and prevents erosion through several mechanisms:

- Load Distribution: The cells distribute applied loads over a wider area, reducing stress on the underlying soil, which prevents rutting and surface deformation.

- Confinement: By confining the soil within each cell, Geocell prevents lateral movement, enhancing shear strength and reducing displacement.

- Erosion Control: Geocell structures hold soil in place on slopes, mitigating soil erosion and enabling vegetation establishment.

- Drainage: Perforations or gaps between cells facilitate drainage, preventing water buildup and reducing hydrostatic pressure.

- Flexible Design: The flexible nature allows Geocell to adapt to varying terrain and soil types, making it suitable for roadbeds, retaining walls, and slope stabilization.

How is Geocell manufactured?

Materials Used

- Primary Material: High-Density Polyethylene (HDPE)

- Additives: UV stabilizers, carbon black, and other compounds to enhance durability and environmental resistance.

Manufacturing Steps

Raw Material Preparation

- Selection: High-quality HDPE resin is selected.

- Blending: HDPE is blended with additives to improve the performance characteristics of the final product.

Extrusion

- Heating: The blended material is heated to a specific temperature to achieve a molten state.

- Extrusion Process: The molten HDPE is extruded through a flat die to form continuous sheets of the desired thickness.

Sheet Formation

- Cooling: The extruded sheets are cooled using air or water to solidify the material.

- Cutting: The cooled sheets are cut into desired sizes based on the specifications of the Geocell.

Texturing (Optional)

- Embossing: Some Geocell products may undergo a texturing process to enhance soil interaction. This involves passing the sheets through rollers that emboss patterns onto the surface.

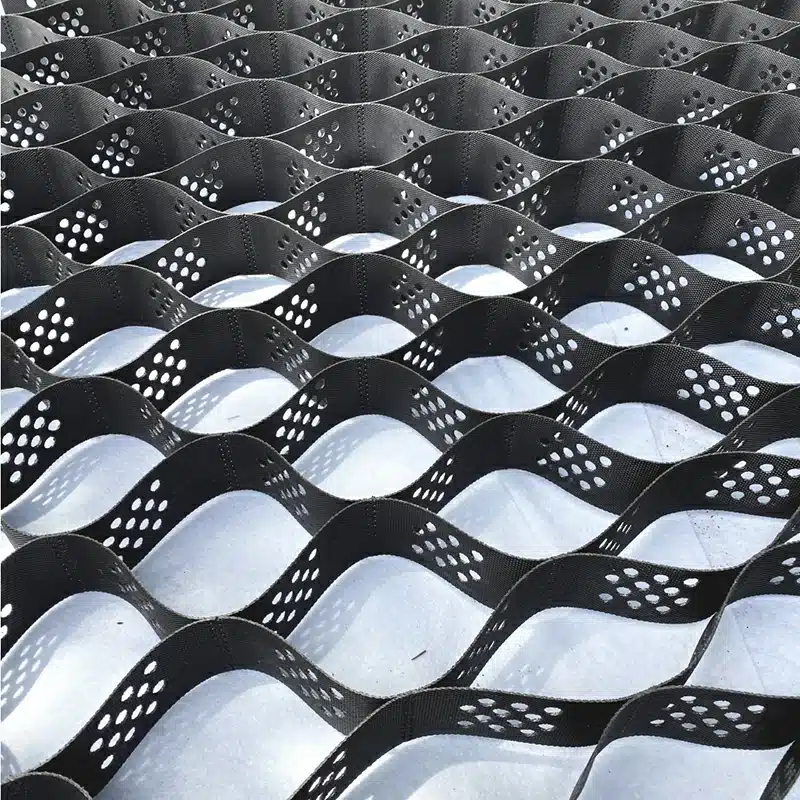

Perforation

- Punching: The sheets are perforated using a punching machine to create the interconnected cell structure. This is a critical step that determines the final shape and size of the cells.

Welding

- Ultrasonic Welding: The perforated sheets are welded together at specific intervals using ultrasonic welding technology. This forms the expandable honeycomb-like structure of the Geocell.

- Quality Check: Each weld is inspected to ensure structural integrity.

Expansion and Folding

- Expansion: The welded sheets are expanded to form the Geocell‘s honeycomb structure.

- Folding: The expanded Geocell is folded into compact bundles for easy transportation and storage.

Packaging

- Bundling: The folded Geocells are bundled and wrapped in protective material.

- Labeling: Each bundle is labeled with product information and specifications.

- Shipping: The final products are prepared for shipment to customers.

Techniques and Machinery

- Extruders: For forming HDPE sheets.

- Embossing Rollers: For texturing the sheets.

- Punching Machines: For creating perforations.

- Ultrasonic Welding Machines: For welding the sheets into a honeycomb structure.

- Quality Control Equipment: For inspecting welds and ensuring product standards.

This structured approach to manufacturing Geocell ensures a high-quality product that meets the necessary performance criteria for various geotechnical applications.

How is Geocell environmentally friendly?

Geocell demonstrates its commitment to environmental sustainability and conservation in several specific ways:

- Energy Efficiency: Geocell employs energy-efficient technologies in its operations, reducing overall energy consumption. Implementation of renewable energy sources, such as solar or wind power, to minimize reliance on fossil fuels.

- Waste Management: Geocell practices responsible waste management by recycling and properly disposing of electronic waste. Reduction of single-use plastics in packaging and operations.

- Carbon Footprint Reduction: Adoption of measures to lower carbon emissions, such as optimizing transportation logistics and using low-emission vehicles. Participation in carbon offset programs to neutralize the company’s carbon footprint.

- Sustainable Products and Services: Offering eco-friendly products and services that have minimal environmental impact. Ensuring that products are designed for durability and recyclability.

- Corporate Social Responsibility (CSR): Active involvement in community projects aimed at environmental conservation and education. support for reforestation and biodiversity initiatives.

- Water Conservation: Implementation of water-saving technologies in their facilities. Encouraging water conservation practices among employees and customers.

Geocell represents a significant advancement in soil stabilization technology, offering a blend of strength, flexibility, and environmental compatibility. Its unique cellular structure, combined with the use of recyclable materials, positions it as an ideal solution for a wide range of construction challenges. By understanding the manufacturing process, applications, and benefits of Geocell, stakeholders in the construction industry can make informed decisions that contribute to sustainable and resilient infrastructure development.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)