+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

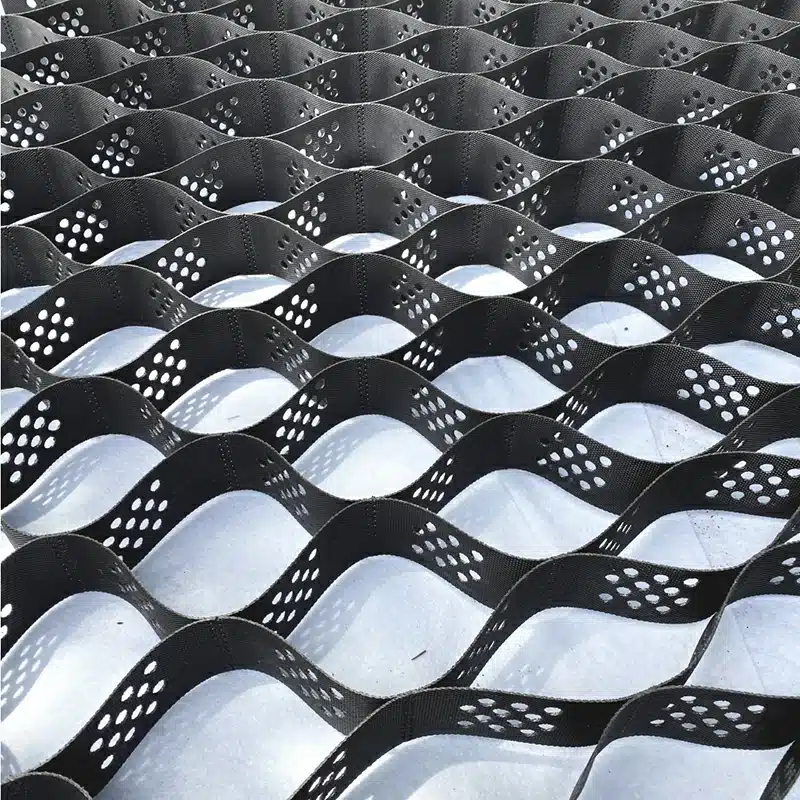

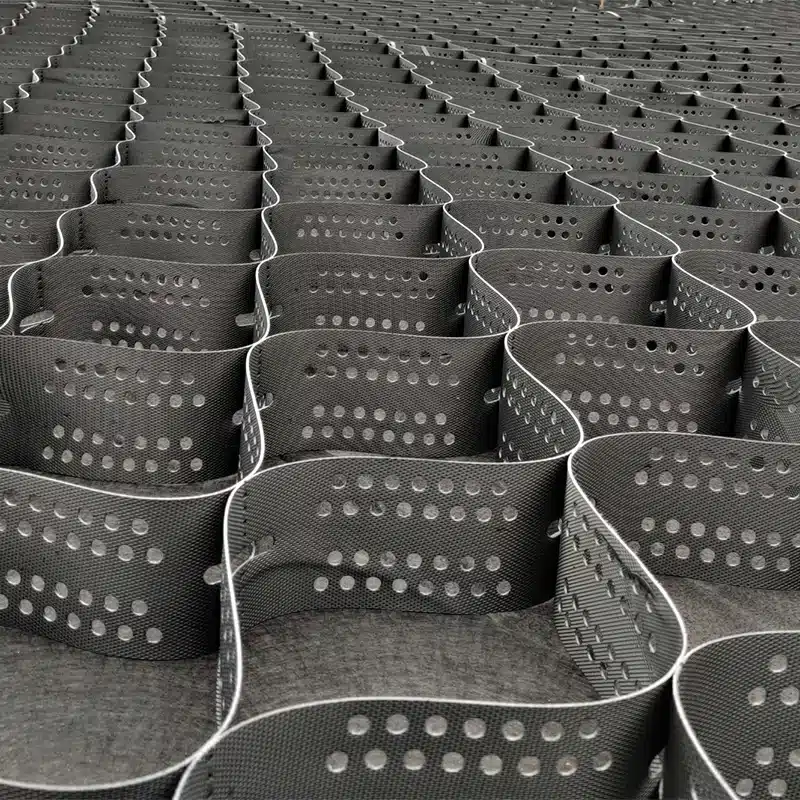

Geocell technology has become an essential solution in modern road construction, providing enhanced stability, improved load distribution, and long-term durability for a wide range of projects. These honeycomb-like structures are designed to reinforce roadbeds, making them ideal for areas with weak soils or heavy traffic. For more details, see Geocell solutions.

What is geocell in road construction?

A geocell is a three-dimensional, honeycomb structure used to stabilize and reinforce soils in road construction. Typically made from HDPE or other durable polymers, geocells are filled with compacted soil, aggregate, or concrete depending on the project.

- Soil Stabilization: Confines fill material to prevent displacement and increase bearing capacity of soft soils.

- Load Distribution: Spreads traffic loads over a wider area, reducing pressure and minimizing rutting.

- Erosion Prevention: Protects underlying soils from erosion caused by water or traffic.

- Durable Roadbeds: Creates long-lasting, stable foundations, even on weak or unstable ground.

See Geocell applications for roadbeds for detailed use cases.

What is the geocell method?

The geocell method is a civil engineering technique for stabilizing and reinforcing weak or loose soils. A geocell is expanded and filled with soil, gravel, or concrete, forming a flexible, load-bearing mat.

Applications:

- Roads and Pavements: Stabilizes weak subgrade soils and reduces excavation needs.

- Slopes and Embankments: Prevents erosion and maintains slope integrity.

- Landfills: Enhances load-bearing capacity and prevents settlement.

- Military and Emergency Roads: Enables rapid construction on unstable ground.

- Retaining Walls: Forms the base of earth-retaining structures.

Advantages:

- Increases load distribution over a larger area.

- Controls surface erosion.

- Reduces fill material usage.

- Cost-effective and faster than traditional stabilization methods.

- Environmentally friendly by minimizing soil excavation and transport.

Learn more about Geocell methods and benefits.

Can you fill the geocell with concrete?

Geocells can be filled with concrete to create highly durable, load-bearing surfaces for demanding road and infrastructure applications.

- Structural Strength: The geocell’s three-dimensional confinement limits concrete shrinkage and cracking, improving structural integrity under heavy loads.

- Enhanced Load Distribution: Concrete-filled geocells distribute traffic loads more evenly, reducing stress concentrations and minimizing surface deformation.

- Improved Durability: This system performs well under repeated traffic loads, temperature variations, and harsh environmental conditions.

- Erosion and Scour Protection: Concrete-filled geocells are highly effective for slope protection, channels, and embankments exposed to flowing water.

- Typical Applications: Roads and access lanes, parking areas, port pavements, retaining wall facings, and slope or channel linings.

Concrete-filled geocell systems combine the flexibility of geosynthetics with the strength of rigid pavement, offering a long-lasting and low-maintenance solution for areas requiring superior stability and erosion resistance.

Geocell technology revolutionizes road construction by improving stability, load distribution, and durability in challenging conditions. Understanding geocells, their method, manufacturing, and concrete-fill potential allows engineers to build stronger, more resilient roads. For additional Geocell road construction insights, visit Geofantex.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)