+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geogrids have become a cornerstone in modern geotechnical engineering, offering unparalleled support in soil stabilization and reinforcement. However, the effectiveness of a geogrid largely depends on selecting the appropriate width, tailored to specific project needs. This article delves into the critical aspects of geogrid width, exploring how to determine the right size, the general requirements, limitations, and the fundamental reasons behind the need for geogrids in construction and landscaping projects.

How wide should a geogrid be for different construction and soil reinforcement applications?

The width of a geogrid depends on the specific project and application:

- Roads and Highways: Typically 1.5–6 meters (5–20 feet) to reinforce pavements and distribute traffic loads.

- Landfills: Can reach 6 meters (20 feet) or more for large-scale soil stabilization.

- Slope Stabilization and Embankments: Usually around 3 meters (10 feet), depending on the slope and project requirements.

- General Soil Reinforcement: Ranges from 1–5 meters (3–16 feet), tailored to the area and soil type.

Selecting the right width ensures optimal load distribution, soil stabilization, and overall project performance. Proper consideration of soil conditions, load-bearing needs, and installation methods is essential for effective geogrid use.

What Are the Key Requirements for Selecting a Geogrid?

Selecting the right geogrid for soil reinforcement and construction projects requires careful consideration of several critical requirements:

- Strength and Tensile Capacity: The geogrid must withstand the expected loads, including traffic, soil weight, or structural pressures, without stretching or failing.

- Durability: Materials should resist UV radiation, chemical exposure, temperature extremes, and long-term environmental degradation to maintain performance.

- Flexibility: While strong, geogrids should conform to the underlying soil or structure, ensuring effective load transfer and soil reinforcement.

- Soil Compatibility: High pullout resistance is necessary to prevent the geogrid from moving relative to surrounding soil or aggregates.

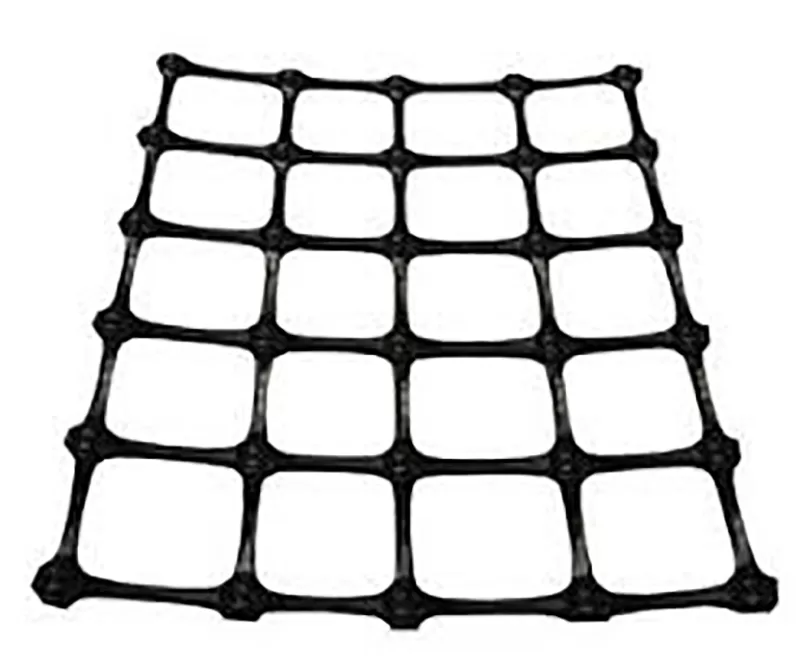

- Aperture Design: Open mesh or grid patterns allow soil or aggregate interlocking, enhancing reinforcement and stability.

- Longevity: The geogrid should maintain structural integrity throughout the project’s design life to ensure reliable performance.

Meeting these requirements ensures that geogrids effectively stabilize soil, reinforce structures, and enhance load distribution, making them essential in roads, embankments, retaining walls, and other civil engineering applications.

What are the limitations of geogrid?

Geogrids have several limitations:

- Performance in Soft Soils: Less effective in very soft or organic soils.

- Installation Damage: Can be damaged during installation, reducing effectiveness.

- UV Degradation: Susceptible to UV degradation if not protected.

- Cost: Higher initial cost compared to other soil reinforcement options.

- Temperature Sensitivity: Performance can be affected by extreme temperatures.

Why do you need Geogrid?

Geogrid is a crucial component in many construction and engineering projects due to its numerous benefits:

- Soil Stabilization: Geogrid helps in stabilizing the soil, which is essential for constructing strong and durable foundations. It prevents soil movement and provides additional support to the ground.

- Load Distribution: It effectively distributes loads over a larger area, reducing the pressure on the soil beneath. This is particularly useful in road construction and other heavy-load-bearing structures.

- Erosion Control: Geogrid plays a significant role in controlling erosion by reinforcing the soil and preventing it from being washed away by water. This is important for projects near water bodies or in areas prone to heavy rainfall.

- Improved Structural Integrity: By using Geogrid, the overall structural integrity of the construction is enhanced. It provides added strength and stability to retaining walls, embankments, and other structures.

- Cost-Effective: Using Geogrid can be more cost-effective compared to other traditional methods of soil stabilization and reinforcement. It often requires less material and labor, leading to overall cost savings.

- Environmental Benefits: Geogrid is often made from recyclable materials and can reduce the need for excavation and soil replacement, making it an environmentally friendly option.

In conclusion, the selection of the appropriate geogrid width is a critical factor in ensuring effective soil stabilization and reinforcement. The width depends on various project-specific factors, including soil type and load requirements. Geogrids must meet certain strength, durability, and compatibility requirements to be effective, but they also have limitations, particularly in certain soil types and environmental conditions. The use of geogrids is indispensable in modern construction and landscaping projects for enhancing soil stability and ensuring the longevity and safety of structures. Understanding these aspects of geogrids empowers engineers and builders to make informed decisions, leading to more successful and sustainable construction projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)