+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the realm of civil engineering and construction, the quest for innovative solutions that enhance efficiency and sustainability is never-ending. Among the myriad of advancements, geogrid technology stands out, especially when applied to temporary working areas. This popular science article delves into the essence of geogrids, exploring their purpose, application in road construction, the materials they are made from, and the optimal timing for their use. By shedding light on these aspects, we aim to provide a comprehensive understanding of how geogrids contribute to the modern construction landscape.

What is the purpose of geogrid?

Geogrids are specifically engineered to reinforce soils and similar materials, thereby enhancing their load-bearing capacity and stability. Their primary function is to evenly distribute loads across a broader area, effectively reducing the pressure exerted on the underlying soil layers. This characteristic is particularly vital in temporary working areas, such as construction sites, where the ground is required to support heavy machinery and materials. By preventing soil displacement and compaction, geogrids play a crucial role in promoting safer and more efficient construction practices, ensuring that soils and similar materials are adequately reinforced for the task at hand.

What is the use of geogrids in road construction?

In road construction, geogrids play a pivotal role in ensuring the longevity and durability of the roadway. By being laid between the subgrade (the native soil) and the road base layer, they create a reinforced foundation that not only withstands the stresses of traffic over time but also increases bearing capacity and ensures longer-term stability and performance. This crucial reinforcement prevents the mixing of subgrade soil with aggregate materials, maintains structural integrity, and minimizes the risk of potholes, rutting, and other forms of degradation. Consequently, the application of geogrids results in a more stable, durable road surface with a potentially longer lifespan and reduced maintenance needs, thereby enhancing the overall quality and reliability of road infrastructure.

What is the most common material used for geogrid?

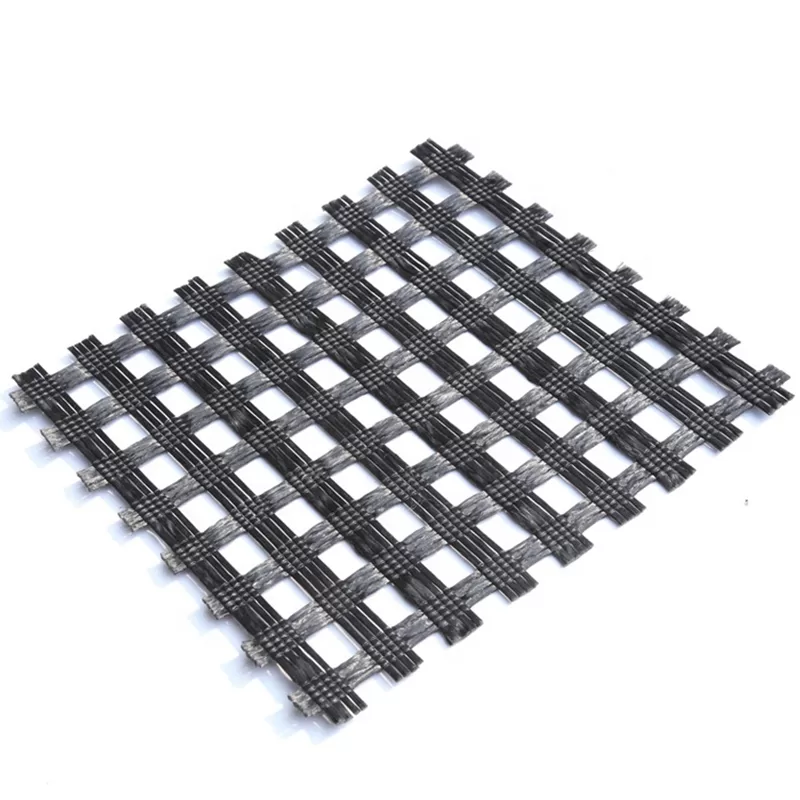

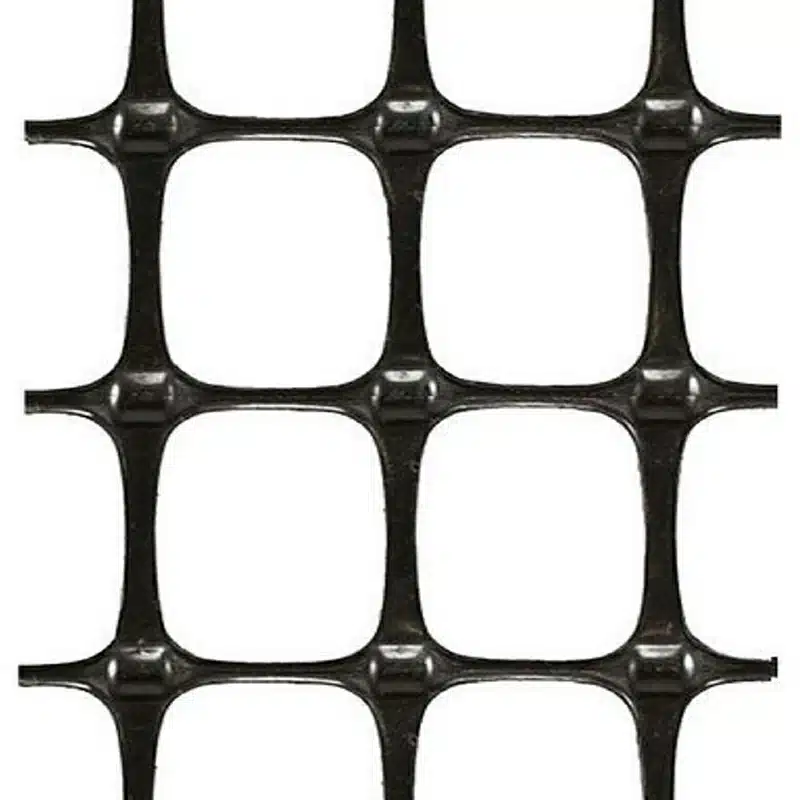

Polypropylene, a type of plastic, is the most common material used for manufacturing geogrids, which are polymers with typically large apertures. Its popularity stems from its exceptional durability, resistance to chemicals, and ability to withstand a wide range of temperatures. Thanks to these large apertures, polypropylene geogrids are also prized for their flexibility, tensile strength, and environmental resistance, making them suitable for various applications, including those in harsh or fluctuating environmental conditions. Additionally, these geogrids are lightweight, easy to install, and offer a cost-effective solution for soil reinforcement needs, further highlighting their adaptability and utility in reinforcing soils and similar materials.

When should geogrid be used?

Geogrid should be used in any construction project where soil stabilization and reinforcement are necessary to ensure the structural integrity and longevity of the project. This includes temporary working areas that need to support heavy equipment, areas with weak or unstable soil, road and railway construction projects, and any application where soil erosion might pose a problem. Geogrids are also essential when constructing on slopes, in areas prone to landslides, or for retaining walls taller than three to four feet, as they help to prevent soil movement and loss. The decision to use geogrids should be based on a thorough analysis of the site conditions, including soil type, load requirements, and environmental factors, ensuring that even structures like tall walls maintain their integrity over time.

Geogrid technology has revolutionized the way we approach construction and civil engineering projects, particularly in temporary working areas and road construction. By reinforcing soil, geogrids enhance its load-bearing capacity, ensuring stability and durability. Made predominantly from polypropylene, these geogrids offer a resilient, cost-effective solution for a myriad of construction challenges. Their application is advised whenever soil stabilization is critical for the success and longevity of a project. As we continue to push the boundaries of construction technology, the role of geogrids in achieving sustainable, efficient, and durable construction practices is undoubtedly set to expand.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)