+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Retaining walls are critical structures used to hold back soil in a variety of landscaping and construction projects. One key component that enhances the stability and longevity of these walls is the geogrid. This popular science article delves into the specifics of geogrids, focusing on their cost, utility, types, and installation requirements, particularly in the context of retaining wall construction.

What is the cost of geogrid?

Geogrids are used to reinforce soils in construction, improving stability and load distribution. The main factors that affect the number of required layers include:

- Soil Type: Sandy soil usually needs more geogrid layers than cohesive soils like clay due to lower shear strength.

- Traffic Load: Moderate traffic requires a moderate level of reinforcement, while heavy traffic needs more layers.

- Wall Height or Fill Depth: Taller retaining walls or deeper fill sections typically require additional geogrid layers.

- Soil Moisture Conditions: Poor drainage or high moisture content can reduce soil strength and increase reinforcement needs.

- Purpose: The application type, such as subgrade stabilization, retaining walls, or roads, determines how loads are distributed in the soil.

Should I use Geogrid for the retaining wall?

Advantages of Using Geogrid for Retaining Walls

- Enhanced Stability: Geogrid provides additional tensile strength, helping to stabilize the soil and prevent wall failure.

- Cost-Effective: Generally, Geogrid can be a cost-effective solution, reducing the need for extensive excavation and other materials.

- Ease of Installation: It is relatively easy to install, which can save time and labor costs.

- Versatility: Geogrid can be used with various wall types and soil conditions, offering flexibility in design and application.

Disadvantages of Using Geogrid for Retaining Walls

- Initial Cost: While cost-effective in the long run, the initial purchase of high-quality Geogrid can be expensive.

- Requires Expertise: Proper installation requires an understanding of engineering principles and may necessitate professional assistance.

- Material Degradation: Over time, Geogrid materials can degrade, especially if exposed to UV light or extreme weather conditions.

Comparison with Other Materials

- Cost: Compared to traditional concrete or stone retaining walls, Geogrid systems can be cheaper in terms of material and labor.

- Durability: Concrete and stone walls are more durable in the long term but lack the flexibility that Geogrid offers.

- Effectiveness: Geogrid excels in providing soil reinforcement, especially in applications where soil conditions are poor.

Factors Making Geogrid a Better or Worse Choice

- Soil Type: Geogrid is particularly effective in poor soil conditions where additional reinforcement is needed.

- Project Scale: For large-scale projects, the cost-effectiveness and ease of installation of Geogrid can be significant benefits.

- Environmental Conditions: Consider the potential for UV exposure and other environmental factors that could affect the longevity of Geogrid.

What is the best geogrid for a retaining wall?

Geogrids are a key element in the design of retaining walls, providing reinforcement and stability. The type of geogrid used can significantly affect the long-term performance and cost-effectiveness of the structure. Several factors, including the soil conditions, height, and material type retained, play a role in determining the best geogrid.

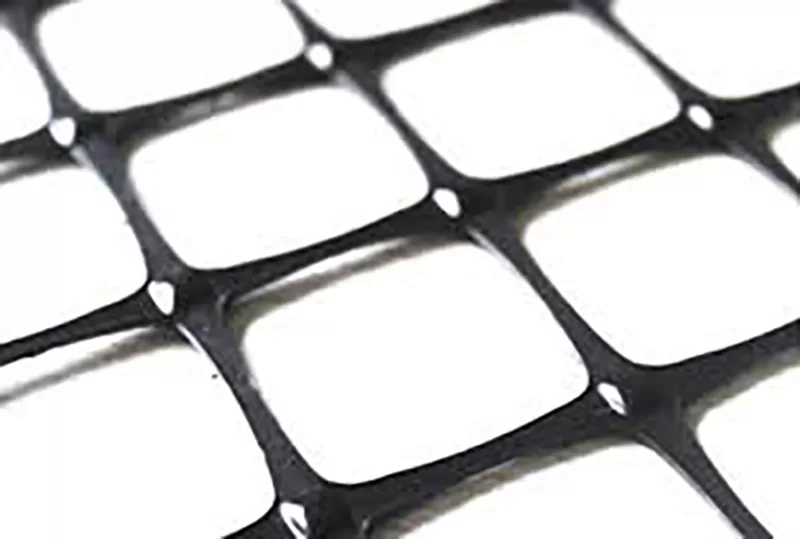

Polymer Geogrids

- Material: Made from polymers such as polyester (PET) or polypropylene (PP).

- Strengths: Highly resistant to corrosion. Lightweight and easy to install. Effective for moderate to heavy soil types. Good long-term durability when exposed to UV light and moisture.

- Ideal Applications: Commonly used for retaining walls

How many layers of geogrid do I need?

Geogrids are used to reinforce soils in construction, improving stability and load distribution. The primary factors that influence the required number of layers include:

- Soil Type: In your case, sandy soil typically requires more reinforcement than cohesive soils (clay), due to its lower shear strength.

- Traffic Load: Moderate traffic implies a requirement for a moderate level of reinforcement, as compared to heavy traffic, which would need more layers.

- Purpose: Whether for subgrade stabilization, retaining walls, or road construction, the design purpose influences how the load is spread across the soil.

Calculation Method:

- Soil Type Consideration: Sandy soils generally have low shear strength. The standard approach is to increase the number of geogrid layers for sandy soils compared to clay or silt soils.

- Load Distribution: For moderate traffic loads, you will likely need at least 2-3 layers of geogrid.A common guideline is the use of one layer per 12-18 inches of fill material for moderate loading.

- Industry Formulas: The number of geogrid layers can be estimated using formulas like the Reinforced Soil Structure Design (RSSD) equation, which relates geogrid properties, soil properties, and load requirements. In general: N=LD×CN = \frac{L}{D} \times C where: NN is the number of geogrid layers, LL is the length of the reinforcement zone, DD is the depth of the reinforced soil, CC is a constant based on soil type and load requirements.

- Guidelines: For typical subgrade stabilization in sandy soils with moderate traffic, 2-3 layers of geogrid are often recommended. For higher loads or where deeper soil layers need reinforcement, up to 4 layers may be required.

Assumptions:

- Standard geogrid materials with typical tensile strength and aperture sizes.

- Moderate traffic loads and typical weather conditions.

- Standard fill material (sand with low fines content).

Recommendations:

- For your project with sandy soil and moderate traffic, 2-3 layers of geogrid should be sufficient for subgrade stabilization.

- Consider increasing the number of layers to 3-4 if the road will experience higher loads or if there is significant moisture variation in the soil.

This approach will ensure sufficient reinforcement and prevent failure or deformation of the soil under the specified traffic conditions.

Geogrids are an essential component in modern retaining wall construction, offering enhanced stability and longevity. While the cost of geogrids can vary, their inclusion in a retaining wall project is often a wise investment in terms of long-term durability and performance. The choice of geogrid type and the number of layers should be tailored to the specific needs of the project, guided by professional advice. By understanding these aspects, homeowners and builders can make informed decisions that ensure the structural integrity and cost-effectiveness of their retaining walls.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)