+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

When dealing with geomembranes, it’s vital to grasp the variety of types and liners used in industrial and environmental applications. In this article, we’ll explore the three main types of geomembranes and delve into the available liners. We’ll also make a direct comparison between PVC geomembranes, known for their flexibility and ease of handling, and HDPE geomembranes, recognized for their toughness and lack of flexibility.

What are the Different Types of Geomembrane Liners?

Here are the different types of geomembrane liners, summarized in bullet points:

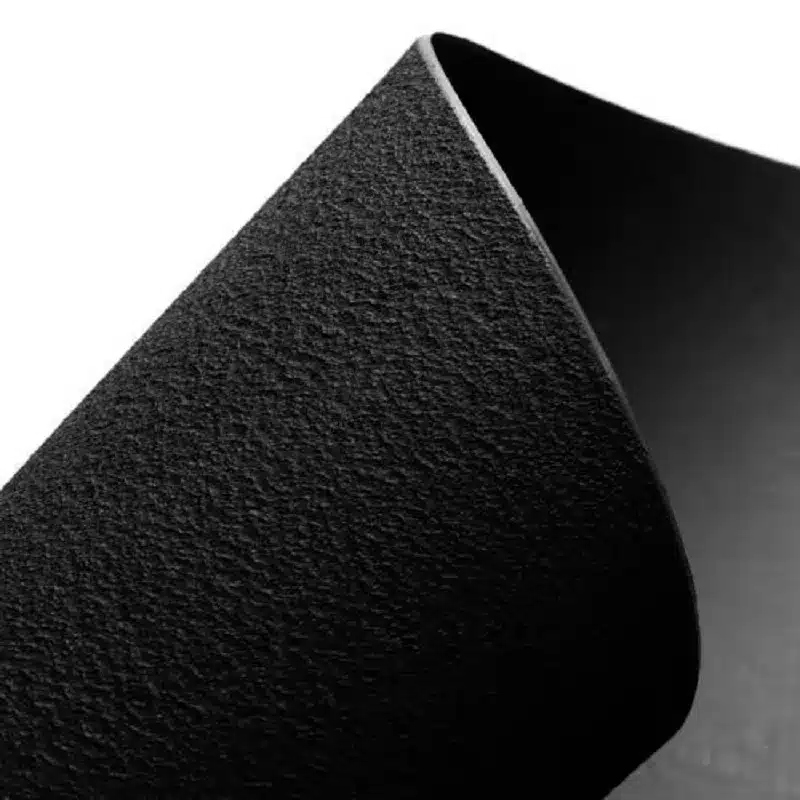

- HDPE (High-Density Polyethylene): The most widely used type, known for its excellent chemical resistance, UV stability, and low permeability. It’s ideal for landfills, mining, and wastewater treatment, but is less flexible and harder to install in cold weather.

- LLDPE (Linear Low-Density Polyethylene): Offers greater flexibility and elongation than HDPE, making it suitable for projects that require liners to conform to uneven surfaces. Commonly used in ponds and canals.

- PVC (Polyvinyl Chloride): A soft, flexible liner that’s easy to seam and install. It’s commonly used in decorative ponds, agriculture, and canal linings. However, it has lower UV and chemical resistance compared to HDPE and LLDPE.

- EPDM (Ethylene Propylene Diene Monomer): A synthetic rubber liner known for superior flexibility and weather resistance. It’s widely used in landscaping, reservoirs, and ornamental ponds. It is more expensive and has lower chemical resistance.

- RPE (Reinforced Polyethylene): A lightweight, durable liner with reinforced layers for added strength. It’s commonly used in stormwater containment, agriculture, and temporary covers. Easy to handle and install.

- CSPE (Chlorosulfonated Polyethylene): Known for its long-term UV and ozone resistance, it is suitable for reservoirs and floating covers. Although durable, it is less commonly used today due to higher costs.

Each geomembrane type offers specific benefits, and the best choice depends on the project’s environmental conditions, durability needs, and budget.

What is the Difference Between HDPE and LLDPE Geomembrane?

HDPE (High-Density Polyethylene) and LLDPE (Linear Low-Density Polyethylene) geomembranes are both widely used for containment and lining applications, but they have distinct differences in terms of material properties and performance.

| HDPE | LLDPE | |

| Density and Structure | Has a high molecular density, providing a more rigid structure. This gives it better resistance to punctures, tears, and UV degradation. | Has a lower density, resulting in a more flexible structure. It is more resistant to cracking and has higher elongation properties compared to HDPE. |

| Flexibility and Strength | Less flexible but stronger under stress due to its higher density. It is ideal for applications where resistance to mechanical damage and environmental stress cracking is crucial. | More flexible, making it better suited for applications where flexibility and elongation are essential. It can adapt to more uneven surfaces but may not be as strong in terms of puncture resistance. |

| Chemical Resistance | Both materials offer excellent chemical resistance, but HDPE is often preferred for aggressive chemical environments due to its denser molecular structure. LLDPE, while still resistant, may not perform as well in some extreme chemical conditions. | Both materials offer excellent chemical resistance, but HDPE is often preferred for aggressive chemical environments due to its denser molecular structure. LLDPE, while still resistant, may not perform as well in some extreme chemical conditions. |

| Temperature Resistance | Performs better in high-temperature environments compared to LLDPE, as it has a higher melting point. | More suitable for environments with low to moderate temperature fluctuations but may degrade quicker in high-heat conditions. |

| Cost | HDPE is generally more expensive due to its manufacturing process and higher material strength. | LLDPE tends to be more cost-effective, particularly for applications where flexibility is a priority over high mechanical strength. |

| Applications | Commonly used in landfill liners, pond liners, and containment applications where high resistance to punctures, chemicals, and UV exposure is needed. | Often used for applications where flexibility is needed, such as in water containment, irrigation, and certain pond lining applications. |

| Summary | Higher density, stronger, more puncture-resistant, less flexible. | Lower density, more flexible, better elongation, but slightly less resistant to punctures and chemicals compared to HDPE. |

Both types of geomembranes have their strengths and are selected based on specific project requirements.

Which Geomembrane Is Best for My Project?

Choosing the right geomembrane depends on several factors:

- Application type: HDPE is ideal for landfills, mining, and wastewater containment; LLDPE works well for irrigation canals and uneven surfaces; PVC and EPDM are suitable for decorative ponds and landscaping.

- Environmental conditions: CSPE or EPDM offer superior UV and weather resistance, while HDPE is preferred for aggressive chemical exposure.

- Installation considerations: PVC and LLDPE are easier to handle and seam in tight or irregular areas, whereas HDPE and RPE are more durable for large open areas.

- Budget and longevity: HDPE and CSPE have higher upfront costs but long-term performance, while LLDPE or PVC may be more cost-effective but may require more maintenance.

- Consultation and compliance: Always consult with a geomembrane expert and ensure materials meet relevant standards such as EPA, ASTM, or GRI-GM. Ultimately, your choice should balance flexibility, durability, chemical and UV resistance, ease of installation, and cost.

Are All Geomembranes Environmentally Safe?

Not all geomembranes offer the same level of environmental safety, and their impact depends on the material composition, application, and how well they are installed and maintained. Here’s a more detailed breakdown:

- Engineered for Containment: Most geomembranes—especially HDPE, LLDPE, and EPDM—are manufactured to be chemically inert, UV-resistant, and non-toxic, making them suitable for environmental protection in applications like landfills, mining, and wastewater treatment.

- Material Composition Matters: Some materials, such as PVC geomembranes, may include plasticizers, stabilizers, or additives that could leach over time under certain environmental conditions, especially if the material degrades or is exposed to high temperatures.

- Installation Quality Is Critical: Even the most environmentally stable geomembrane can fail if improperly installed, leading to leakage of hazardous substances and groundwater contamination. Seam quality, surface preparation, and anchoring all play vital roles in minimizing environmental risk.

- End-of-Life Considerations: Geomembranes must be disposed of responsibly or, where possible, recycled. Certain polymers are more recyclable than others, with HDPE and LLDPE generally having better end-of-life recycling pathways compared to more complex materials like CSPE or PVC.

- Regulatory Compliance: Geomembrane materials used in environmental containment must often meet strict local and international standards, such as EPA, ASTM, or GRI-GM specifications, to ensure they are safe for long-term use.

Understanding geomembrane types is essential for selecting the right liner. Whether you’re comparing HDPE vs. LLDPE or exploring flexible options like PVC, this guide helps you make informed decisions based on performance, application, and environmental impact.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)