+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

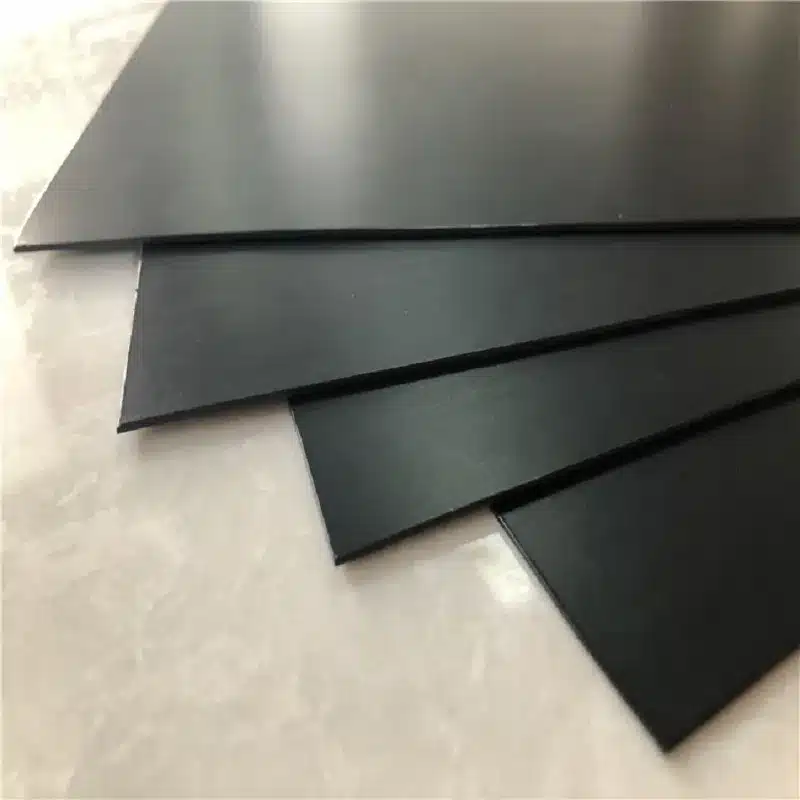

HDPE geomembrane liners are globally recognized as the most commonly employed geomembranes, largely due to their widespread availability and cost-effectiveness. These liners find extensive usage in international projects, particularly in large-scale applications that necessitate UV and ozone resistance, chemical resistance, or high-quality installations.

HDPE geomembrane liners are used in a variety of applications including mining, landfill, and chemical processing.

What is the function of a geomembrane liner?

A geomembrane liner is a type of synthetic material used to create a barrier that prevents the movement of liquids or gases. It is commonly used in a variety of applications, particularly in environmental protection and civil engineering projects. The key functions of a geomembrane liner include:

Containment and Isolation:

- Primary Function: The most important function of a geomembrane liner is to prevent the migration of harmful substances (such as hazardous liquids, leachates, or chemicals) from one area to another. For example, it is used in landfills to contain waste and prevent contaminants from leaking into the surrounding soil and groundwater.

Waterproofing:

- Waterproofing: In applications like ponds, reservoirs, and irrigation systems, geomembranes are used to line the base and sides to prevent water from leaking out or being absorbed by the surrounding soil. This helps to maintain water levels and minimize water loss due to seepage.

Slope Stability and Erosion Control:

- Slope Protection: Geomembranes are often used in combination with other geosynthetics like geogrids or geotextiles to enhance slope stability. They prevent erosion and reduce the risk of landslides or instability in areas with loose or unconsolidated soils.

Chemical Resistance:

- Durability: Geomembranes are designed to be resistant to a wide range of chemicals, making them ideal for industrial applications where chemical containment is crucial. For instance, they are used in the lining of chemical storage tanks, ponds, and industrial sites where toxic substances might be present.

Environmental Protection:

- Environmental Safeguarding: They are widely used in the construction of containment ponds, waste treatment plants, and other facilities that require environmental safeguards. By providing a durable, impermeable layer, geomembrane liners help to protect ecosystems from contamination and ensure regulatory compliance.

Gas Barrier Function:

- Gas Control: Geomembranes also prevent the movement of gases, such as methane, from landfills or other waste containment sites. This is important for safety, as it helps to prevent explosions or the migration of harmful gases into nearby communities.

The geomembrane liner serves primarily as a barrier to liquids and gases, ensuring the containment of harmful substances and protecting both the environment and surrounding communities from contamination. Its durability, chemical resistance, and ability to provide waterproofing and slope stability make it a key component in various engineering and environmental protection projects.

What material is geomembrane lining made of?

Geomembrane linings are typically made from synthetic polymers that provide excellent impermeability and chemical resistance. The most common materials used include:

High-Density Polyethylene (HDPE):

- Popular for its strength, durability, and resistance to chemicals and UV rays.

- Often used in landfill liners, water reservoirs, and wastewater treatment applications.

Low-Density Polyethylene (LDPE):

- More flexible than HDPE, suitable for applications requiring adaptability to uneven surfaces.

Linear Low-Density Polyethylene (LLDPE):

- Combines flexibility with strength, ideal for geomembrane applications requiring ease of installation and durability.

Polyvinyl Chloride (PVC):

- Flexible and easy to install, commonly used in smaller-scale projects like decorative ponds or temporary barriers.

Ethylene Propylene Diene Monomer (EPDM):

- A synthetic rubber material, highly elastic and suitable for projects requiring extreme flexibility, such as fish ponds or reservoirs.

Reinforced Polypropylene (RPP):

- A robust and versatile material, often used in industrial settings.

These materials are chosen based on their specific properties, including resistance to environmental stress, chemical exposure, and physical durability, making geomembrane linings suitable for various containment and environmental protection applications.

What is the difference between geomembrane and pond liner?

Geomembrane Liners Are More Impermeable

Leaks can occur with any material, however, they are much less likely to happen when a geomembrane is specified. Pond liner is an impermeable geomembrane used for the retention of liquids.

Is geomembrane waterproof?

Geomembranes are waterproof sheets that are used as hydraulic barriers. They are available in different widths and packed in rolls joined by different techniques such as thermofusion, welding, adhesive, vulcanization methods, etc.

Geomembranes are synthetic membrane liners or barriers used to control fluid migration in a manmade project, structure, or system. They are made from relatively thin continuous polymeric sheets that are sometimes made from the infusion of geotextiles with asphalt, elastomer, or polymer sprays.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)